1-4

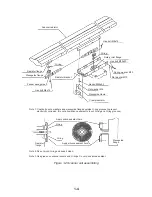

Scanner radiator

Radiator flange

Waveguide flange

Feeder waveguide

Hex bolt M6x16

Radiator bracket

O-ring

Clamp insulator

Waveguide clamp

Flat washer M6

Hex bolt M6x50

Flat washer M10

Spring washer M10

Hex bolt M10x20

Rotary joint flange

O-ring

Hex bolt M6x16

Apply silicone sealant here.

O-ring

Radiator

flange

Apply silicone sealant here.

O-ring

Waveguide

flange

Note 1: Coat bolts, nuts, washers and waveguide flanges outside O-ring grooves to prevent

electrolytic corrosion. (Do not allow silicone sealant to touch O-ring and O-ring grooves.)

Note 2: Do not pinch O-ring and keep it clean.

Note 3: Use grease on scanner covers and O-rings. Do not use silicone sealant.

Figure 1-2 Scanner unit assembling

Summary of Contents for FR-2165DS

Page 1: ...MARINE RADAR MODEL FR 2165DS...

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......