En-12

7.

PIPE INSTALLATION

CAUTION

Be careful that foreign matter (oil, water, etc.) does not enter

the piping with refrigerant R410A models. Also, when storing

the piping, securely seal the openings by pinching, taping,

etc.

While brazing the pipes, be sure to purge with dry nitrogen

gas.

7.1. Selecting the pipe material

CAUTION

Do not use existing pipes.

Use pipes that have clean external and internal sides without

any contamination which may cause trouble during use, such

as sulfur, oxide, dust, cutting waste, oil, or water.

It is necessary to use seamless copper pipes.

Material : Phosphor deoxidized seamless copper pipes

It is desirable that the amount of residual oil is less than

40 mg/10 m (33 ft).

Do not use copper pipes that have a collapsed, deformed,

or discolored portion (especially on the interior surface).

Otherwise, the expansion valve or capillary tube may become

blocked with contaminants.

Improper pipe selection will degrade performance. As an air

conditioner using R410A incurs pressure higher than when

using conventional refrigerant, it is necessary to choose

adequate materials.

•

Thicknesses of copper pipes used with R410A are as

shown in the table.

•

Never use copper pipes thinner than those indicated in the

table even if they are available on the market.

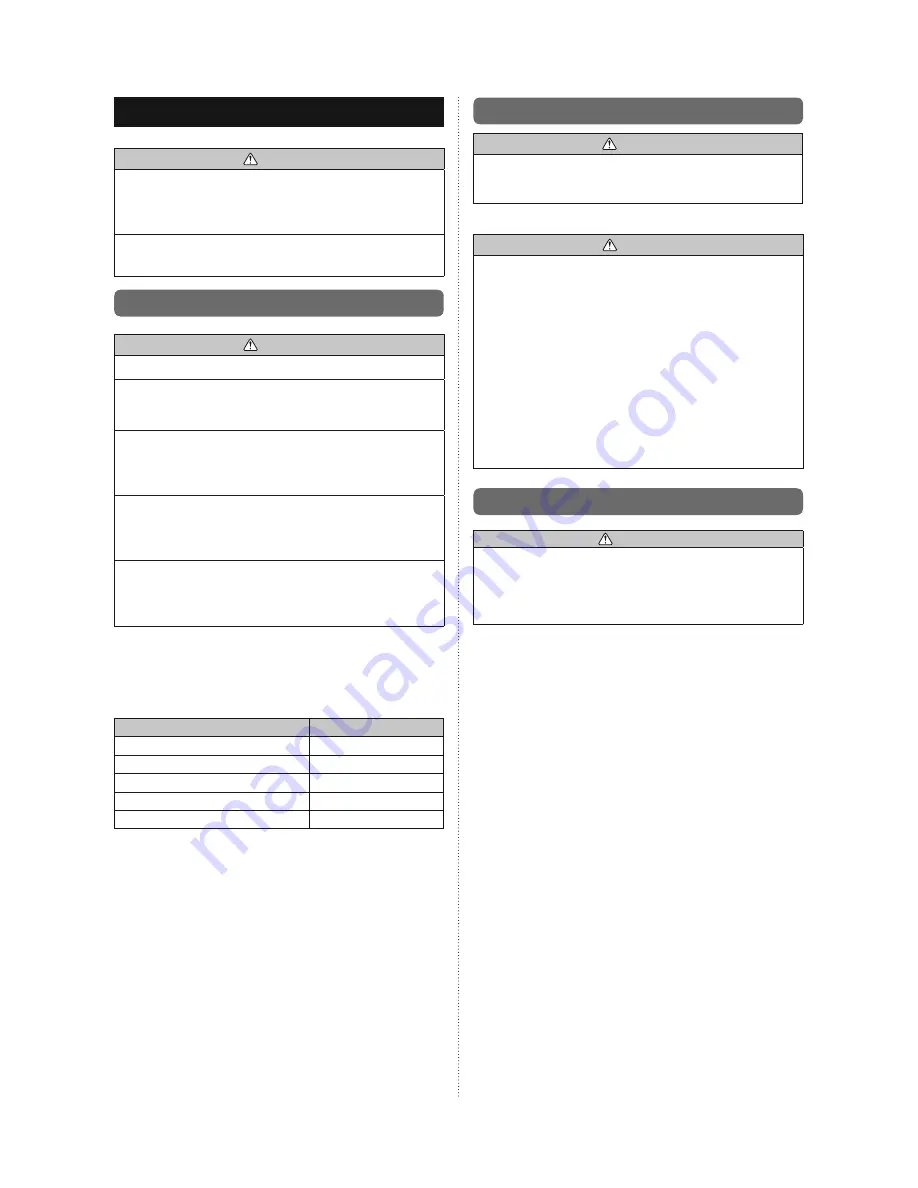

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter [mm (in.)]

Thickness [mm (in.)]

6.35 (1/4)

0.80 (0.032)

9.52 (3/8)

0.80 (0.032)

12.70 (1/2)

0.80 (0.032)

15.88 (5/8)

1.00 (0.039)

19.05 (3/4)

1.20 (0.047)

7.2. Pipe requirement

CAUTION

Refer to the Installation Manual of the outdoor unit for

description of the length of connecting pipe or for difference

of its elevation.

• Use pipe with water-resistant heat insulation.

CAUTION

Install heat insulation around both the gas and liquid pipes.

Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 248°F.

(Reverse cycle model only)

In addition, if the humidity level at the installation location

of the refrigerant piping is expected to exceed 70 %,

install heat insulation around the refrigerant piping. If the

expected humidity level is 70-80 %, use heat insulation

that is 15mm(19/32 in.) or thicker and if the expected

h u m i d i t y e x c e e d s 8 0 % , u s e h e a t i n s u l a t i o n t h a t i s

20mm(25/32 in.) or thicker. If heat insulation is used

that is not as thick as specified, condensation may form

on the surface of the insulation. In addition, use heat

insulation with heat conductivity of 0.045 W/(m·K) or less

(at 68°F).

7.3. Flare connection (Pipe connection)

WARNING

Tighten the flare nuts with a torque wrench using the

specified tightening method. Otherwise, the flare nuts could

break after a prolonged period, causing refrigerant to leak

and generate a hazardous gas if the refrigerant comes into

contact with a flame.

7.3.1. Flaring

• Use special pipe cutter and flare tool exclusive for R410A.

(1)

Cut the connection pipe to the necessary length with a

pipe cutter.

(2)

Hold the pipe downward so that cuttings will not enter the

pipe and remove any burrs.

(3)

Insert the flare nut (always use the flare nut attached to

the indoor and outdoor units respectively) onto the pipe

and perform the flare processing with a flare tool. Use

the special R410A flare tool, or the conventional flare

tool. Leakage of refrigerant may result if other flare nuts

are used.

(4)

Protect the pipes by pinching them or with tape to

prevent dust, dirt, or water from entering the pipes.