INP-TN5A1634-E

21

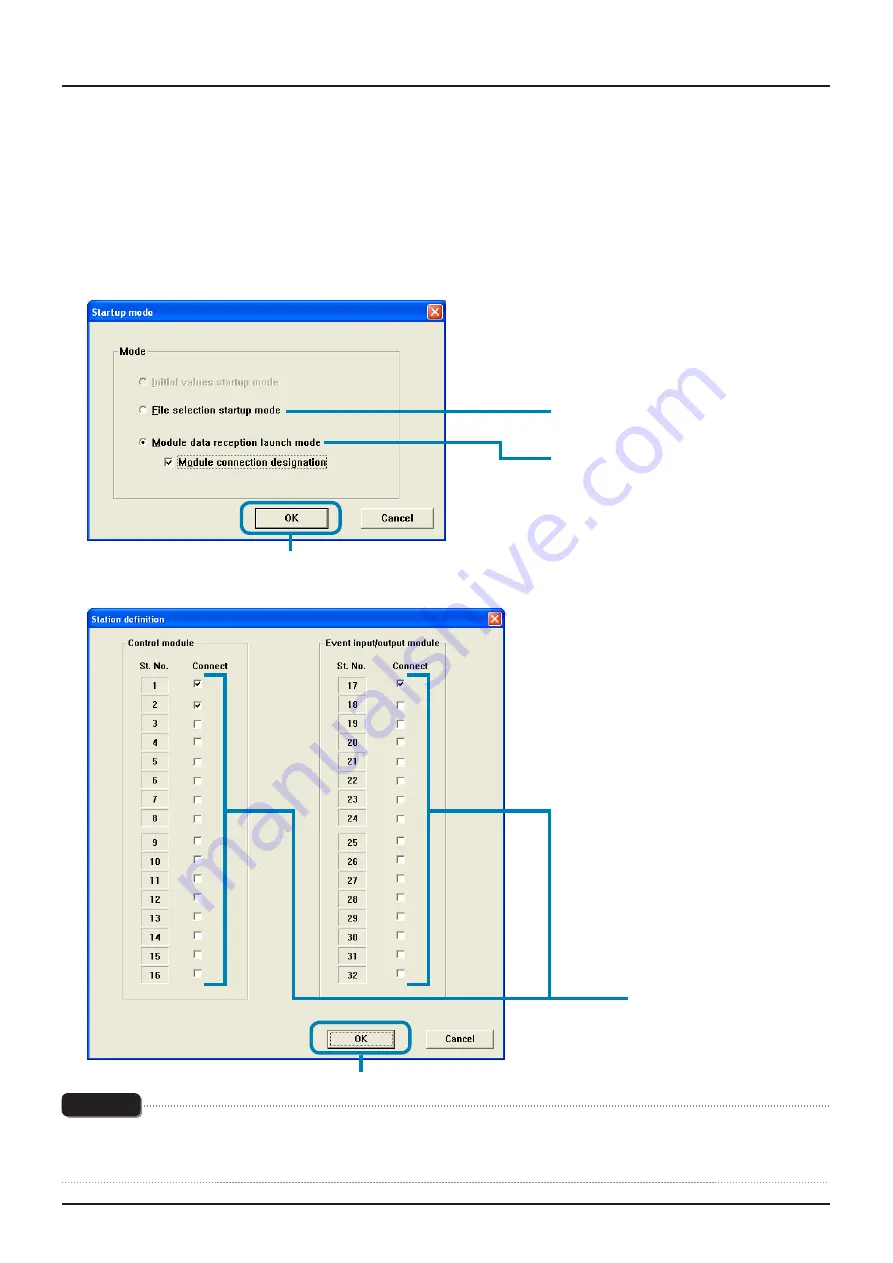

Reading the setting by selecting the Station No. of the module-type temperature

controllers connected

This method is not available when selected the “Enhanced comm module [Mitsubishi's programless comm]”, “Profibus comm

module [Profibus comm]”, “Ethernet comm module [Ethernet comm]” on the “module type selection”.

1

Select “Module data reception launch mode” on the “Startup mode” screen, check “Module connection designation,” and

click [OK].

(3) Click.

(1) Click.

(2) Check.

2

Check the St No. of the module-type temperature controller to be read on the “Station definition” screen, and then click [OK].

(1) Check.

*1

(2) Click.

Note

Do not check the ST No. of the controller that is not connected. Otherwise a communication error occurs. The “communication

error” message does not appear in this case. (The reading from the module-type temperature controller connected is performed

normally.)

*1: Select from the Station Numbers of "Control

module" with Analog module.