7

Before installation/maintenance, the tractor and mower should be

stationary with the hydraulic lift system in a neutral position and the

ignition key removed.

On a flat area of ground lower the three point linkage on the tractor to its

lowest position. Attach the mower to the tractor using the three point

linkage pins and linch pins:

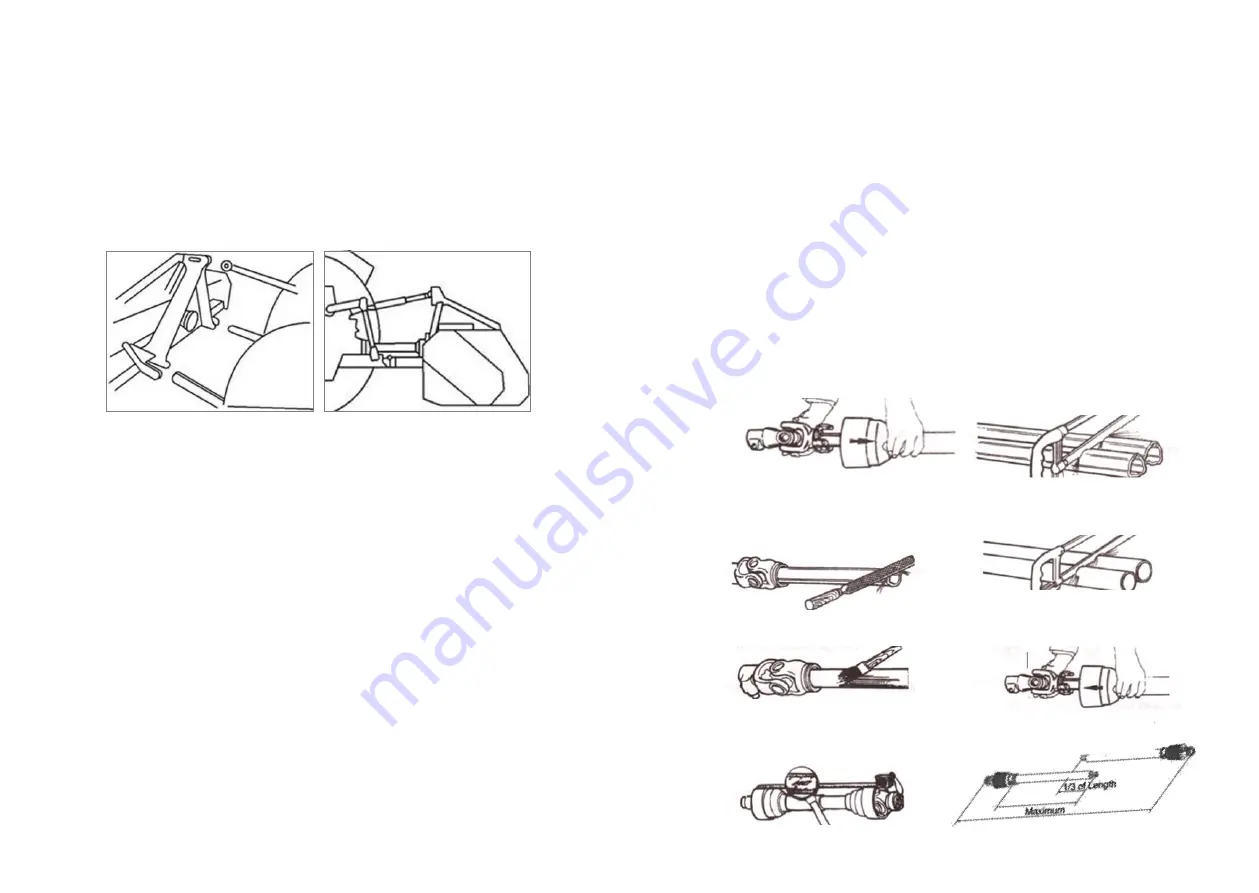

Installation Overview

With the mower

’

s rear roller on the ground, adjust the length of the top

link arm so that the skids at the side of the mower are parallel with the

ground.

To set correct cutting height, rotate the blade rotor by hand, so they hang

vertically towards the ground. There should be a clearance of at least 5cm

between the blades and the ground. To increase the blade clearance and

cutting height for rough ground or long grass, raise the tractor

’

s hydraulic

lift arm or adjust the rear roller and skids on the mower.

The working speed of the mower should be at a walking pace of 2 to 5

mph. Overgrown grass/weeds should be cut at a much slower pace to

avoid damage to the mower.

Check the oil level in the gearbox, the tension of the drive belts and

tightness of all bolts, nuts and screws. Lubricate all grease points including

PTO drive shaft. Attach the PTO drive shaft and ensure locking pin is

secure on both the tractor and mower sides. Attach the chain to a secure

point on the tractor/mower. Ensure all safety guards are in place.

Always

replace worn or damaged

PTO drive shafts.

Operate the mower in a low gear range, keep the PTO output at 540 rpm.

8

Resizing the PTO Drive Shaft

Before installation/maintenance, the tractor and mower should be

stationary, the hydraulic lift system in a neutral position and the

ignition key removed.

A PTO drive shaft will often need re

-

sizing to fit the tractor. To resize,

attach the mower to the tractor without the PTO drive shaft, raise the

linkage so the PTO drive shaft is level/horizontal. Measure the length

between the tractor

’

s PTO and the PTO drive shaft. If the compressed

(closed) PTO drive shaft length exceeds the one measured in diagram 7

below, then the driveline will need to be cut as per instructions below.

If you are not confident in carrying out this work please contact your local

supplier or mechanic.

1. Remove PTO drive shaft shielding.

2. Cut the driveline tubes to equal

lengths.

3. Use a file to smooth edges of the

driveline tube and clear away all

fillings from the tubes.

4. Cut the guard tubes to the same

length as the driveline tubes.

5. Grease the internal driveline tube.

6. Fit the guard on the shaft.

7. Ensure that the length allows for

at least 16cm (1/3) of overlap