●

For left piping and left rear piping, align the marks on the wall

hook bracket and shape the connection pipe.

●

Bend the connection piping at a bend radius of 2 - 3/4’’(70 mm) or

more and install no more than 1- 3/8’’(35 mm) from the wall.

●

After passing the indoor piping and drain hose through the wall

hole, hang the indoor unit on the hooks at the top and bottom of

the wall hook bracket.

[Installing the indoor unit]

●

Hang the indoor unit from the hooks at the top of the wall hook

bracket.

●

Insert the spacer, etc. between the indoor unit and the wall hook

bracket and separate the bottom of the indoor unit from the wall.

Fig. 4

After hooking the indoor unit to the top hook, hook the fittings of the

indoor unit to the two bottom hooks while lowering the unit and

pushing it against the wall.

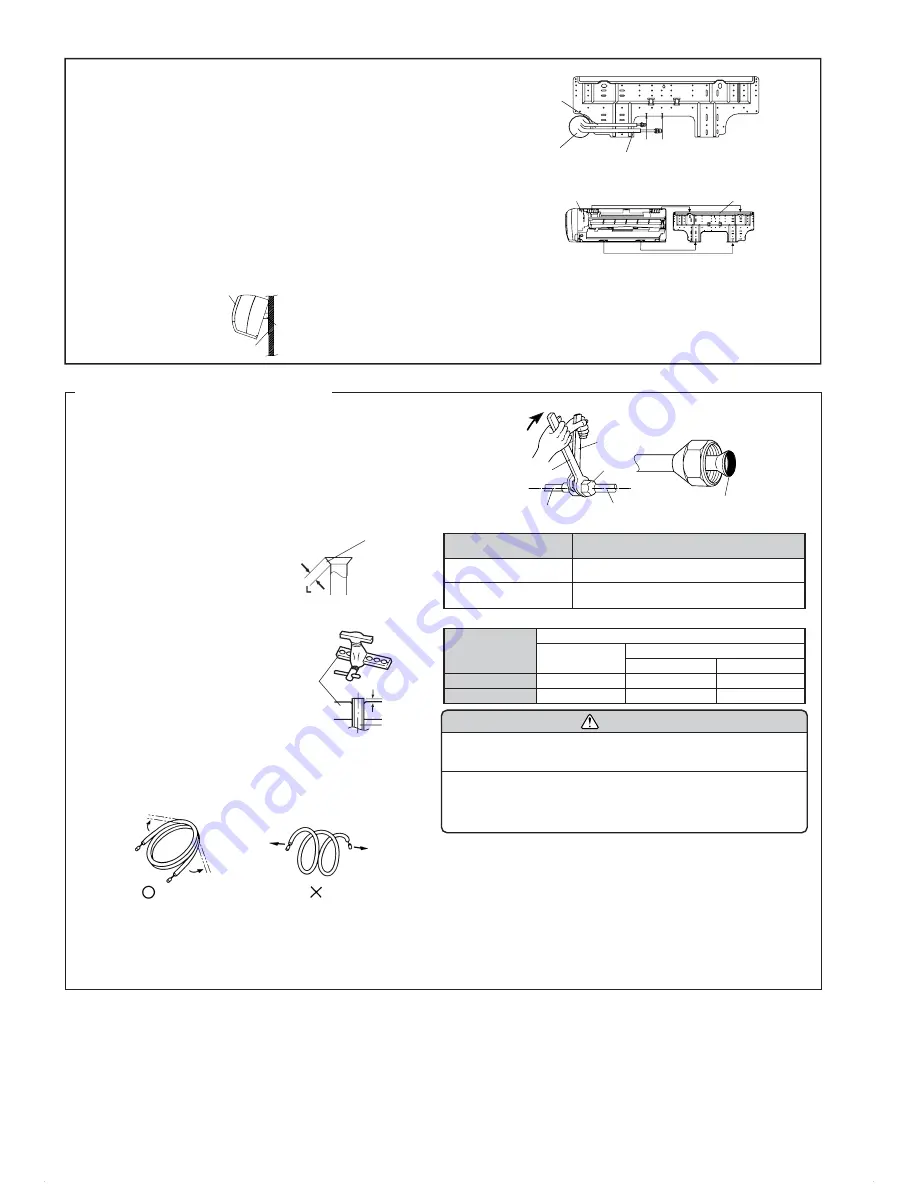

BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse them.

Do not bend the pipes in an angle more than 90°.

When pipes are repeatedly bent or stretched, the material will harden,

making it difficult to bend or stretch them any more. Do not bend or stretch

the pipes more than three times.

Top hooks

Indoor unit

Bottom hooks

Wall hook bracket

Connection pipe

(1/4” (6.35 mm)

dia.)

Connection pipe

(3/8” (9.52 mm) dia.)

Align the marks.

Bend (R70) with

a pipe bender

Indoor unit

Wall hook bracket

(Spacer)

CONNECTION

(1) Install the outdoor unit wall cap (supplied with the optional installa-

tion set or procured at the site) to the wall pipe.

(2) Connect the outdoor unit and indoor unit piping.

(3) After matching the center of the flare surface and tightening the nut

hand tight, tighten the nut to the specified tightening torque with a

torque wrench. (Table 2)

FLARING

(1) Cut the connection pipe to the nec-

essary length with a pipe cutter.

(2) Hold the pipe downward so that

cuttings will not enter the pipe and

remove the burrs.

(3) Insert the flare nut onto the pipe

and flare the pipe with a flaring

tool.

Insert the flare nut (always use the flare

nut attached to the indoor and outdoor

units respectively) onto the pipe and

perform the flare processing with a

flare tool.

Use the special R410A flare tool, or

the conventional (for R22) flare tool.

When using the conventional flare tool,

always use an allowance adjustment

gauge and secure the A dimension

shown in table 3 .

CONNECTING THE PIPING

Check if [L] is flared uniformly

and is not cracked or scratched.

Table 2

Flare nut tightening torque

Table 3

Pipe outside diameter

Flare nut

1/4” (6.35 mm) dia.

3/8” (9.52 mm) dia.

Tightening torque

11.57 to 13.20 ft

•

lbs

(160 to 180 kgf

•

cm)

21.70 to 30.38 ft

•

lbs

(300 to 420 kgf

•

cm)

A (in)

Pipe outside

diameter

1/4” (6.35 mm)

3/8” (9.52 mm)

Flare tool for

R410A, clutch type

0 to 1/32

0 to 1/32

Conventional (R22) flare tool

Clutch type

1/32 to 2/32

1/32 to 2/32

Wing nut type

2/32 to 3/32

2/32 to 3/32

CAUTION

(1) Fasten a flare nut with a torque wrench as instructed in this manual. If

fastened too tight, the flare nut may be broken after a long period of time

and cause a leakage of refrigerant.

(2) During installation, make sure that the refrigerant pipe is attached firmly

before you run the compressor. Do not operate the compressor under the

condition of refrigerant piping not attached properly with 2-way or 3-way

valve open. This may cause abnormal pressure in the refrigeration cycle

that leads to breakage and even injury.

Fig. 5

Tighten with two wrenches.

Torque

wrench

Wrench (fixed)

Flare nut

Indoor unit pipe

Connection pipe

To prevent gas leakage, coat the flare

surface with refrigerator oil.

Die

A

Pipe

OK

NO

Extend the pipe

by unwinding it.