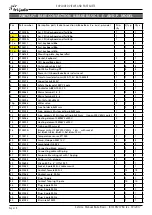

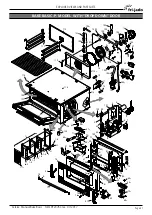

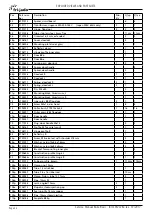

EXPLODED VIEWS AND PARTSLISTS

Page 36

Service Manual Bake Basic form 9123763 rev. 07/2017

Part

number

Description

Qty

Fasteners

0142103

Washer M5, SS

4,0

0142111

Washer M6, SS

1,0

0142292

Nut M3, SS

8,0

3701066

Steelcable 1,25mm ZNP

6,0

3701222

Spring, 0,8mm pull

8,0

3701237

Press bolt M3x25, ZNP

8,0

3703095

Bolt M6x90, hexagon head, SS

4,0

4285131

Rivet nut M6, Monel

4,0

4285152

Starlock washer

1,0

8048311

Bolt M6x70, hexagon head, SS

4,0

9174680

Washer M5, Ø20mm, 3mm thick

1,0

Wire and Terminals

0260155

Wire AWG18, blacj

9,28

2005658

Bootlace ferrule, Blue 9mm

11,0

2005755

Ringterminal, M4 Blue

4,0

2005763

Ringterminal, M5 Blue

2,0

2005933

Ringterminal, M4 Red

1,0

2005941

Ringterminal, M5 Red

2,0

2005967

Splice, Red

1,0

2006133

Receptacle, female Blue

1,0

2006159

Ringterminal M4, uninsulated

6,0

2006183

Receptacle, female Red, full insulated

2,0

2006206

Spade terminal, Red

4,0

2006222

Receptacle, female Red piggyback

1,0

2006303

Bootlace ferrule, Grey 0,75 qmm

21,0

2006353

Receptacle, uninsulated

11,0

4310287

Wire 2,5qmm, green/yellow

8031502

Receptacle insulation boot, 6,3x0,9

5,0

9070654

Wire AWG14, black

2,86

Stickers

3500105

Sticker, Lightning sign

3,0

9123148

Sticker, High temperature

5,0

9123277

Sticker, Distance to wall 10cm

1,0

9123478

Sticker, wastebin

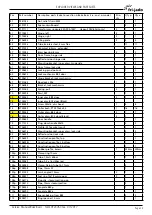

Part

number

Description

Qty

Miscellaneous

3702322

Isolation BB3 rear, 770x360

1,0

3702323

Isolation BB3 surround, 2000x540

1,0

3702336

Insulation sleeve, Ø12x3 silicon

0,4

3702337

Insulation sleeve, Ø10x4 silicon

0,4

3702361

Isolation BB top 570x80

1,0

3702388

Isolation BB5 rear, 770x560

1,0

3702389

Isolation BB5 2440x540

1,0

3706166

Corner support, doorgasket

4,0

4302375

Sealant, Dowcorning black, 0,31 ltr

0,5

3701278

Tube with silicon grease.

9077088

Din rail

1,0

9123573

User manual

1,0

0194930

Loctite 542 (for bolt in door handle)

GENERAL PARTS NOT MENTIONED IN DRAWINGS