19

4. Using cable cutters, cut off one inch of the end of

the cable.

IMPORTANT: Other tools may flatten

or bend the cable strands so that it may be dif-

ficult for you to reinsert the cable into the cable

clip.

5. Cut off one inch of the black sheath from the end of

the cable.

6. Reinsert the cable and the sheath into the cable

clip so that all of the bare cable is in the hole.

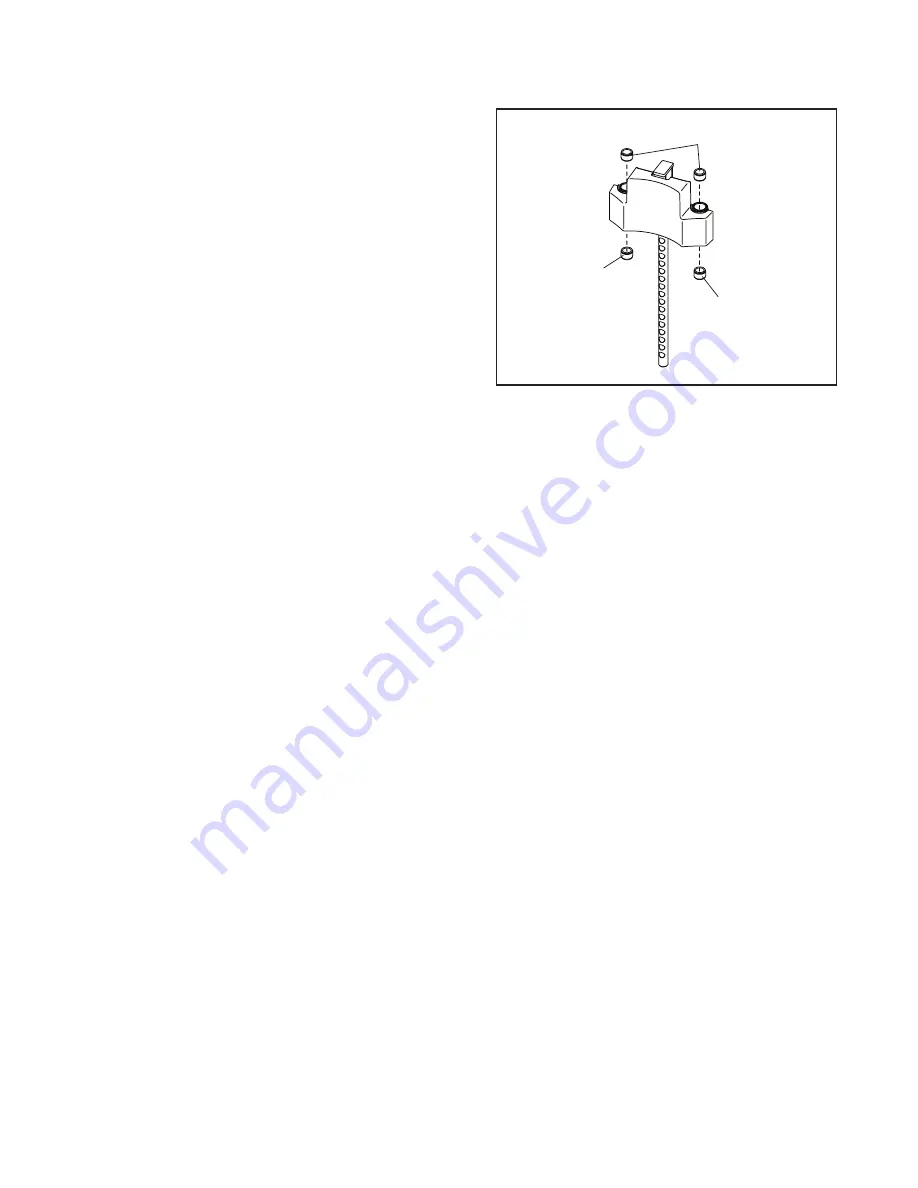

7. Retighten the four set screws equally until they

contact the cable. Then, tighten each set screw

alternately 1/4 turn, until all are set to 85 inch/

pounds (9.6 Newton-meters).

8. Slide the cable stop onto the cable clip, remove the

weight pin, and lower the handle.

9. Check for proper tension on the cable as described

in CABLE ADJUSTMENT on page 18.

WEIGHT STACK SERVICING

Servicing the weight stack involves replacing the bush-

ings in the weight carriages. To order new bushings,

see HOW TO CONTACT CUSTOMER CARE on the

back cover of this manual. Note: Replacing the bush-

ing requires a hammer, a punch, and a piece of scrap

wood.

Follow the steps below to service each weight stack.

1. Remove the screws and the cap from the top of

the strength equipment. Next, remove the screws

and the access cover from the back of the strength

equipment.

2. Remove the nuts and washers from the upper

ends of the weight guides, and let the weight

guides slide down to the floor.

3. Slide the weight carriage upward off the tops of the

weight guides. Note: Pull the weight guides toward

the back of the strength equipment for increased

clearance.

4. Using a punch, drive the four old bushings out of

the weight carriage.

5. Hold one of the new bushings square with the face

of one of the holes in the weight carriage, place

a piece of scrap wood on top of the bushing, and

tap the bushing into place until the bushing is flush

with the hole in the weight carriage.

Insert the

other three new bushings in the same way.

6. Clean and lubricate the weight guides by wiping

them with a soft cloth containing 10W-40 or 10W-

30 lightweight motor oil. Apply only a light coating

over the entire length.

Do not use TEFLON

®

-

based lubricants.

7. Slide the weight carriage onto the weight guides.

8. Reattach the weight guides to the top of the tower

with the nuts and washers.

9. Slowly perform a repetition and have someone

make sure that the cable is not derailed from a pul-

ley or rubbing on a cable trap.

10. Reattach the access cover and the cap.

Bushings

Bushing

Bushing