5

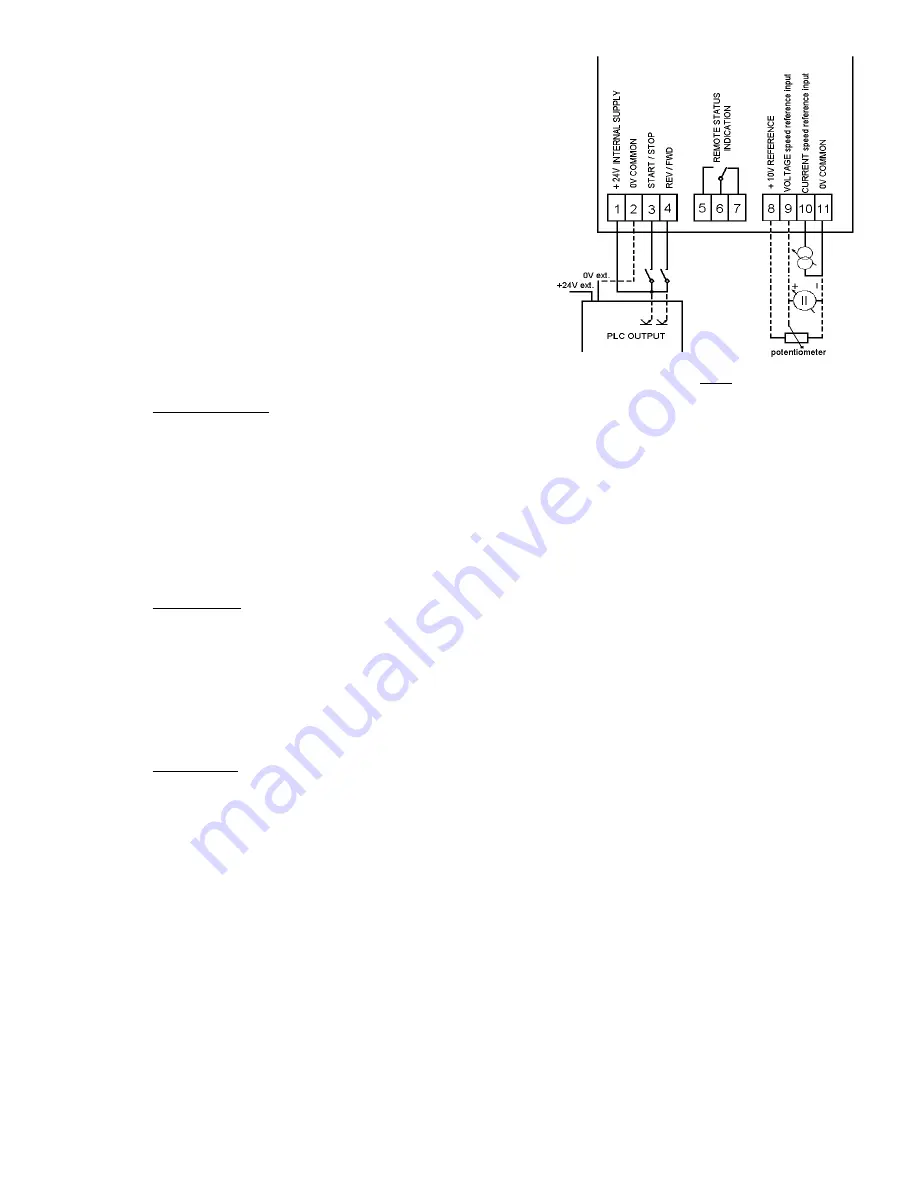

5.3. Control connections

5.3.1. Connection procedure

•

remove the front panel that is secured with screws.

•

for control connections use cable of 0,5 mm

2

screened

•

connection cable should enter at bottom.

•

connect screen to earth at the drive only .

•

connect control cable to terminals

(connections are shown in FIG 2).

•

refit the front panel

NOTE : always segregate control and power cabling !

5.3.2. Specifications of control inputs and outputs

Complete isolation between control and power electronic circuits.

•

Analogue inputs

- speed control

current input : 0

÷

20 mA (4

÷

20 mA)

120

Ω

input impedance

voltage input : 0

÷

10 V (2

÷

10 V)

67 k

Ω

input impedance

potentiometer : 2

÷

20 k

Ω

recommended value 10 k

Ω

•

Logic inputs

- run/stop : control switch or PLC output

- forward/reverse : control switch or PLC output

Input voltage : min : 15 V

DC

Input current : approx. 8,5 mA (24 V

DC

)

nominal : 24 V

DC

max : 30 V

DC

Input signal delay : max 5 ms

•

Logic output

- drive status : volt-free change-over relay contact - 250 V

AC

;

8 A

6. Drive status indication

6.1. On the front panel of the drive

•

LED "POWER" (red) : input voltage is present, all internal voltage levels are correct

•

LED "FAILURE" (red) : internal or external trip (e.g. overvoltage, overcurrent, short-circuit ...)

the drive is stopped (disconnected from the load)

6.2. Remote indication

•

Volt-free change-over relay contact

Control terminals :

5

- normally open

6

- common

7

- normally closed

Relay energised when : drive healthy

Relay de - energised when : power off or drive tripped (disconnected from the load)

FIG. 2