2

MAINTENANCE

LUBRICATION:

Lubricate the bearings with a proper ball

bearing grease through the grease nipples provided. Do

not over lubricate. Ball bearings require a surprisingly small

amount of grease. Over lubrication causes the bearing to

break down because the grease then tends to churn and

produce heat. If this temperature goes above 200°F, it will

break down causing the bearing to fail. Units supplied with

sealed bearings are not equipped with grease nipples, no

maintenance required.

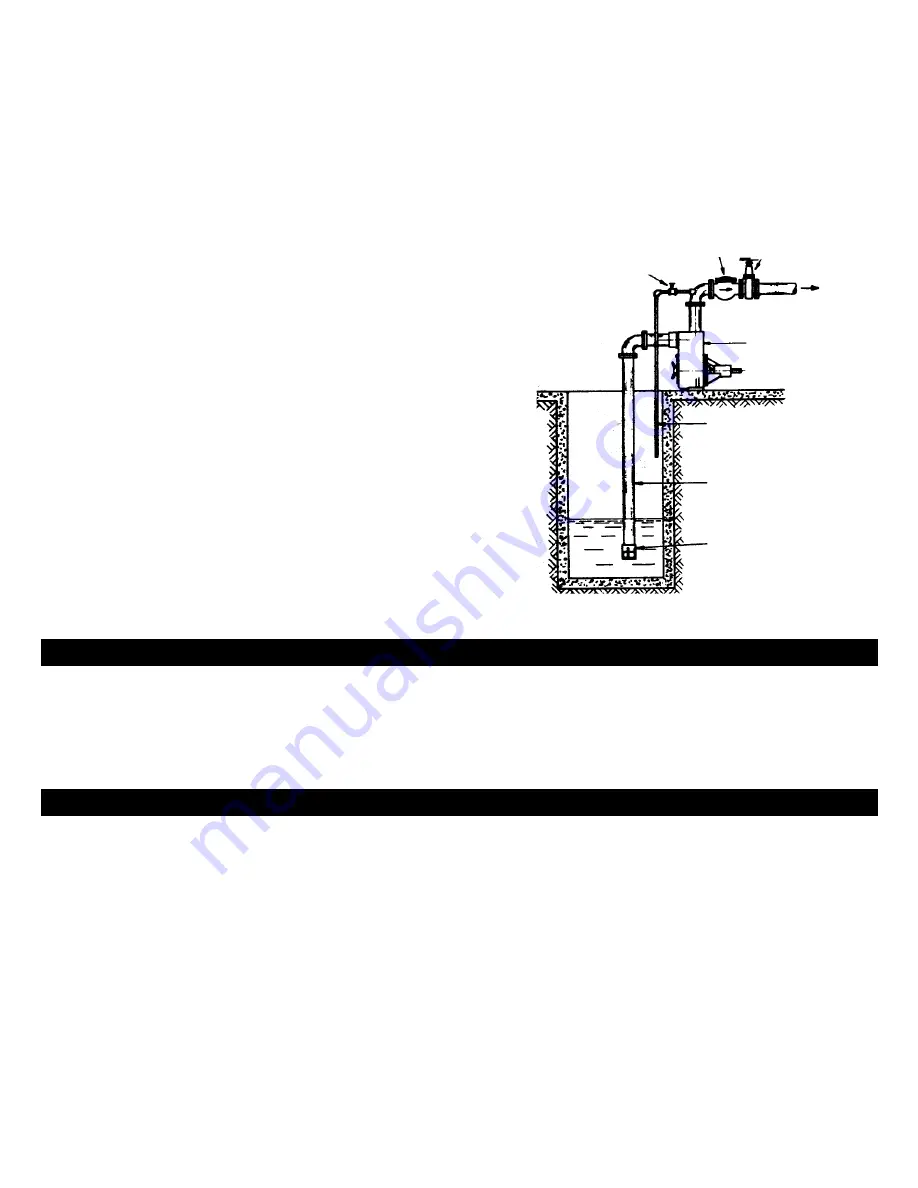

Gate Valve (min. 3/4")

Check Valve

Gate Valve

Discharge

Pump

Air Bleed Line

Suction Pipe

Strainer

FIG. 1

This enables the pump to prime quickly and prevents

kinking or breaks in the hose. In cases where a maximum

volume of water is required over a prolonged period of

time, the suction line should be led horizontally to the

pump.

c) DRAINING:

During freezing temperatures, the pump

should be drained each time it is stopped for any

appreciable length of time. To drain, remove the drain

plug at the bottom of the pump casing and make sure

that the drain hole is not plugged. After all the water has

been drained from the pump casing, the unit should be

operated for a few seconds so that all of the water will be

removed from the impeller.

NOTE:

The pump should also be drained after corrosive

liquids have been pumped.

d) UNCLOGGING:

Should the pump become clogged it can

easily be cleaned out as outlined below.

1) Remove the wing nuts (75).

2) Pry the clean out cover (78) loose with a screwdriver

using the specially fitted lugs on the cover.

3) Remove the cleanout cover.

4) Clean out the interior of the pump making sure the check

valve is also clean.

5) Replace the cleanout cover making sure the O-ring is

clean and in place.

A clogged impeller results in excessive vibration. Should this

occur, the impeller must be cleaned out immediately to avoid

serious damage to the unit.

These pumps offer the added feature of removing the

impeller and seal through the clean out cover for service or

replacement.

REPAIR

TO DISASSEMBLE

(Fig. 2)

:

1. Remove the six nuts (530C) and then remove transmission

head (79).

2. Remove the head bolt (510).

3. Remove impeller (2) by unscrewing it in a counter-

clockwise direction.

4. Slip the rotating seal (90) off the shaft.

5. When replacing stationary seat, remove the adapter

plate (3) from the transmission head and press out the

stationary seat.

TO ASSEMBLE:

1. Clean all parts thoroughly before assembling.

2. Apply liquid soap on rubber cup on stationary seat and

push it into the adapter plate using thumbs only. Make sure

the smooth surface of the ceramic seat faces outwards.

3. Slide the adapter plate over the shaft being very careful

not to damage the stationary seat.

4. Slip the rotating seal onto the shaft with the seal ring

towards the stationary seat.

5. Reassemble the impeller to the shaft.

6. Bolt the transmission head to the pump.

NOTE:

Replacing Parts: When replacing either the body,

wear plate, impeller or shaft, the clearance between the

impeller and the wear plate should be checked. This clear-

ance should be about .020 inches to .035 inches. If it is less,

the impeller will rub against the wear plate causing undue

wear and increase the load. If the clearance is greater, an

increased amount of recirculation will take place causing

a decrease in efficiency and increase priming time. This

tolerance may be achieved by the addition or removal of

gaskets.