P a g e

|

34

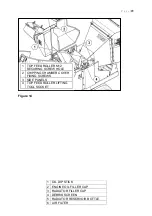

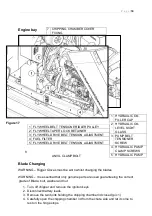

All drive belts are located under the engine cover as shown in Figure 16 and Figure

17 and tension checked at arrows shown in Figure 21. Check and set tension as

follows:

1. Slacken clamp screw(s) or nut (6).

2. Hydraulic pump adjuster screw requires its lock nut to be slackened (5).

3. Turn adjuster nut or screw (4) to tension belt until 4.5Kg force at the belt

longest centre span deflects by 6mm (see Figure 21). Can be approximated

by firmly gripping belt between finger and thumb and twisting. The belt should

not be able to be rotated more than 90°.

4. Tighten all lock nuts, nuts and clamp screws (5 & 6).

5. Run machine and test.

6. Check belt tension.

Figure 21

1 FLYWHEEL DRIVE BELTS.

CHECK TENSION HERE

2 HYDRAULIC PUMP DRIVE BELT. CHECK TENSION

HERE

3 HYDRAULIC OIL LEVEL IN SIGHT GLASS

Summary of Contents for TR6

Page 5: ...P a g e 4 ...