P a g e

|

18

Always monitor the state of chip flow out of the chute. If this stops,

STOP FEEDING

MATERIAL IMMEDIATELY

. Continuing to feed material will further compact a

blockage and make it more difficult to clear.

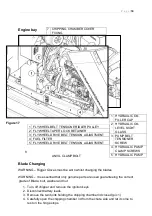

If the chipping chamber or chute become blocked:

1. Stop the engine and remove ignition key.

2. Remove chute and check that it is clear.

3. If the chipping chamber is blocked, open the engine cover, then chipping

chamber cover.

DO NOT REACH INTO THE CHIPPING CHAMBER WITH

HANDS.

Beware that the flywheel within the chipping chamber has two sharp

blades mounted on it and can move causing a serious injury risk. Wearing

protective gloves and using a piece of wood, carefully clean out the chipping

chamber.

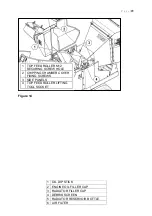

If feed becomes jammed (see Figure 7):

1. Stop the engine and remove ignition key.

2. Open engine and chipping chamber covers.

3. Release feed roller spring tension on both sides by slackening off the eye bolt

nuts and remove if necessary.

4. Insert feed lift tool and lift top feed roller to fully open.

5. Insert M12 screw into side of feed chamber and screw completely in. Lower

top feed roller onto the screw to secure in the open position.

6. There should now be access to the feed chamber. Beware that this is the

machines cutting zone. The top and bottom feed rollers have sharp teeth and

the flywheel cutting blades are not far from them.

DO NOT PUT HANDS

INTO THIS AREA.

Wearing protective gloves and using a piece of wood,

carefully clear jammed material inside feed chamber.

7. When clear, lift top feed roller via lifting tool, remove top feed M12 securing

screw, lower top feed roller and remove lifting tool.

8. Re-assemble feed tensioner springs and replace covers.

Summary of Contents for TR6

Page 5: ...P a g e 4 ...