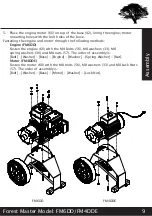

Forest Master Model: FM6DD/FM4DDE

12

Engine Operation for FM6DD Petrol Chipper

Starting the Engine

• Position your wood chipper on flat, dry ground and make sure the machine

cannot be moved.

• Before starting, manually turn the drum to make sure it is not obstructed and

moves smoothly.

• Make sure the fuel shut-off valve is in the “ON” position.

• Move the choke control lever to the “CHOKE” position (should only be needed if

the engine is warm or not starting).

• Move the throttle control lever to the “FAST” position.

• Turn the ignition switch to the “ON” position.

• Grasp the recoil starter handle and slowly pull until you feel resistance. Let the

cord retract a little bit then pull the cord rapidly to start the engine. One or two

pulls usually starts the engine.

• Move the choke lever (if used for warm engine) slowly back to the “RUN” position

when the engine is running well.

• If the wood chipper has not been running (cold engine), warm up the engine by

running the engine at half throttle for 3 to 4 minutes, then advance the engine

throttle control to chipping speed.

Operation

Operation

NOTE: Higher revs does not necessarily mean more

torque to the blade drum. As you can see from

the power map, the highest amount of torque is

achieved around the 2500 rpm mark, and therefore

is the most efficient speed to maintain the engine

for chipping. We advise you do not increase the

revs to the maximum for chipping unless required,

as this works the engine harder for less results and

could shorten the long-term life span of the engine

(and use more petrol).

Stopping the Engine

• Move the throttle lever to “IDLE”

• Turn the ignition switch to the “OFF” position.