times, then use a proprietary balljoint

separator to break the taper (see illustration).

5 Use a stout piece of wood to lever the lower

arm downwards and free the balljoint from the

stub axle carrier.

6 Remove the ABS wheel sensor from its

hole.

7 Remove the spring clip from one of the

wheel studs and pull the brake disc off the

hub.

8 Remove the stub axle carrier pinch-bolt.

Spread the stub axle carrier by carefully

introducing a chisel or blunt instrument into its

slot. Draw the stub axle carrier off the

suspension strut and remove it.

9 Refit by reversing the removal operations,

noting the following points:

a) Tighten all fastenings to the specified

torque

b) Use new split pins, when applicable

c) Renew the wheel sensor O-ring if

necessary; clean the sensor and its bore,

and smear them with wheel bearing

grease

Models before August 1989

1 Remove the stub axle carrier as described

in the previous Section.

2 Screw the wheel nuts onto the studs to

protect the threads. Clamp the stub axle

carrier in a vice by means of the studs and

nuts; do not overtighten.

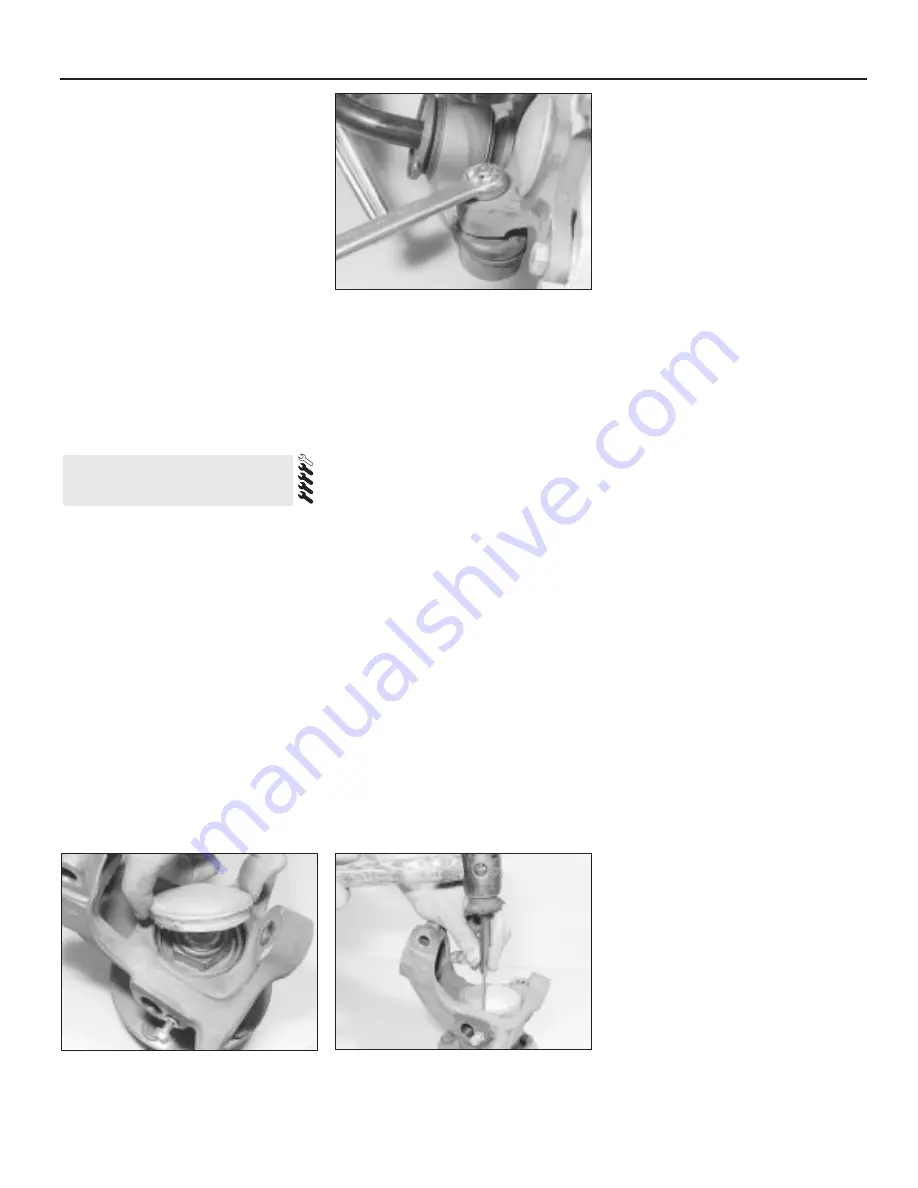

3 Remove the dust cap from the hub nut,

carefully levering it free (see illustration). A

new cap and a new hub nut will be required for

reassembly.

4 Undo the hub nut. This nut is very tight. The

right-hand hub nut has a left-hand thread,

therefore it is undone in a clockwise direction.

5 Remove the ABS rotor from below the hub

nut.

6 Lift the carrier off the stub axle, tapping it

with a mallet if necessary to free it. Remove

the bearing inner race from the carrier.

7 Prise the oil seal out of the carrier and

recover the bearing outer race.

8 Drive the bearing tracks out of the stub axle

carrier using a blunt drift and a hammer. Be

careful not to mark the bearing seats.

9 Clean all old grease and debris from the

stub axle carrier.

10 New bearing components are matched in

production and must only be fitted as a set.

Only the manufacturer’s approved

components should be used in order to obtain

the required long service life and freedom from

adjustment.

11 Drive the new bearing tracks into the

carrier, preferably using a suitable diameter

tube to seat them. Make sure the tracks are

fully seated.

12 Work some clean grease into the bearing

races. Use high melting-point lithium-based

grease (to Ford spec. SAMIC-9111A or

equivalent). Make sure all the spaces between

the rollers are filled; do not pack grease into

the space between the inner and outer

bearings however.

13 Fit the bearing outer race. Grease the lips

of a new oil seal and fit it to the stub axle

carrier, lips facing inwards. Seat the seal with

a pipe or large socket and a mallet.

14 Offer the carrier to the stub axle, tapping it

home if necessary. Fit the bearing inner race

over the stub axle.

15 Refit the ABS rotor, dished face

uppermost.

16 Fit a new hub nut (left-hand thread on the

right-hand hub) and tighten it to the specified

torque.

17 Fit a new dust cap and seat it by tapping

round the rim (see illustration).

18 Refit the stub axle carrier.

Models from August 1989

19 Modified front wheel bearing assemblies

were fitted to all models after 1989. The

modified bearings are of similar design, but

are interference fit type bearings. This was to

reduce the amount of endfloat present at the

wheel hub and to improve bearing preload

tolerances. This was achieved by increasing

the diameter of the stub axle, thus causing the

axle to be an interference fit in the bearing.

Note that the modified bearings can be fitted

to earlier models which were originally

equipped with non-interference fit front wheel

bearings. Note: Due to the design of the

interference fit bearings, a suitable heavy duty

bearing puller and a hydraulic press and

several suitable mandrels will be required to

remove the original bearing and install the new

one.

20 Interference fit front wheel bearings can be

removed and refitted as described above,

noting the following points.

a) It will be necessary to press or draw the

stub axle out of the carrier using a

hydraulic press or a suitable bearing

puller.

b) Draw the outer bearing off the stub axle

using a suitable bearing puller.

c) Press new bearing tracks into the hub

carrier using a suitable tubular spacer

which bears only on the tracks outer edge.

d) Pack the new outer bearing with Ford

grease (SAM-1C9111-A) and press the

bearing into the carrier.

e) Press a new seal into position in the

carrier and pack all cavities with the

specified grease.

f) Position the hub carrier over the stub axle

and press the carrier onto the axle using a

suitable tubular spacer which bears only

on the bearing track outer edge.

g) Pack the new inner bearing with the

specified grease then press the bearing

onto the stub axle, using a suitable tubular

spacer, whilst rotating the hub carrier to

ensure that the bearing is correctly seated.

h) Whilst tightening the hub nut to the

specified torque, rotate the hub carrier to

ensure that the bearing preload is correct

and bearings are correctly seated. Once

the nut is tightened to the specified

torque, rotate the hub carrier 20 times to

settle the bearings in position then

recheck that the hub nut is tightened to

the specified torque. Pack the inner

bearing with the specified grease and fit a

new dust cap.

17 Front wheel bearings -

renewal

11•8 Steering and suspension

16.4 Slackening the front suspension lower

arm balljoint nut

17.17 Seating the new dust cap

17.3 Removing the dust cap from the stub

axle carrier to expose the hub nut

Summary of Contents for Granada 1985-1994

Page 42: ...1 22 Notes...

Page 102: ...2C 22 Notes...

Page 136: ...4 24 Notes...

Page 176: ...11 14 Notes...

Page 196: ...12 20 Notes...

Page 221: ...Wiring diagrams WD 1 WD Diagram 16 Power operated sliding roof...

Page 222: ...WD 2 Wiring diagrams Diagram 2 Power distribution...

Page 223: ...Wiring diagrams WD 3 WD Diagram 2 Power distribution continued...

Page 224: ...WD 4 Wiring diagrams Diagram 3 Charge start and run Part 1...

Page 225: ...Wiring diagrams WD 5 WD Diagram 3 Charge start and run Part 1 continued...

Page 226: ...WD 6 Wiring diagrams Diagram 3A Charge start and run Part 2...

Page 227: ...Wiring diagrams WD 7 WD Diagram 3A Charge start and run Part 2 continued...

Page 228: ...WD 8 Wiring diagrams Diagram 4 Engine management 1 8 litre...

Page 229: ...Wiring diagrams WD 9 WD Diagram 4 Engine management 1 8 litre continued...

Page 230: ...WD 10 Wiring diagrams Diagram 4A Engine management 2 0 litre carburettor...

Page 231: ...Wiring diagrams WD 11 WD Diagram 4A Engine management 2 0 litre carburettor continued...

Page 232: ...WD 12 Wiring diagrams Diagram 5 Engine management 2 0 litre fuel injection...

Page 233: ...Wiring diagrams WD 13 WD Diagram 5 Engine management 2 0 litre fuel injection continued...

Page 234: ...WD 14 Wiring diagrams Diagram 5C Engine management 2 8 litre...

Page 235: ...Wiring diagrams WD 15 WD Diagram 5C Engine management 2 8 litre continued...

Page 236: ...WD 16 Wiring diagrams Diagram 7A Exterior lighting...

Page 237: ...Wiring diagrams WD 17 WD Diagram 7A Exterior lighting continued...

Page 238: ...WD 18 Wiring diagrams Diagram 9 Signalling and warning systems...

Page 239: ...Wiring diagrams WD 19 WD Diagram 9 Signalling and warning systems continued...

Page 240: ...WD 20 Wiring diagrams Diagram 10 Interior lighting...

Page 241: ...Wiring diagrams WD 21 WD Diagram 10 Interior lighting continued...

Page 242: ...WD 22 Wiring diagrams Diagram 12 Wipers and washers...

Page 243: ...Wiring diagrams WD 23 WD Diagram 12 Wipers and washers continued...

Page 244: ...WD 24 Wiring diagrams Diagram 14 Central locking system...

Page 245: ...Wiring diagrams WD 25 WD Diagram 14 Central locking system continued...

Page 246: ...WD 26 Wiring diagrams Diagram 15 Power operated windows...

Page 247: ...Wiring diagrams WD 27 WD Diagram 15 Power operated windows continued...

Page 248: ...WD 28 Wiring diagrams Diagram 21 ABS...

Page 249: ...Wiring diagrams WD 29 WD Diagram 21 ABS continued...

Page 250: ...WD 30 Wiring diagrams Diagram 23 Auxiliary warning system...

Page 251: ...Wiring diagrams WD 31 WD Diagram 23 Auxiliary warning system continued...

Page 252: ...WD 32 Wiring diagrams Diagram 29 Radio cassette player and associated circuits typical...

Page 254: ...WD 34 Wiring diagrams Diagram 11 Heater blower...