4.1

C.H. OUTPUT REGULATION

When the boiler is fuelled with natural gas

(G20), it is possible to change the maxi-

mum pressure value according to the dia-

gram shown in fig. 13 in order to adjust

C.H. output to the thermal requirements of

the system.

If the pressures need to be corrected fol-

low the indications in section 4.3.1. In order

to avoid the variation of the minimum pres-

sure lock the adjusting screw (2 fig. 11/a).

4.2

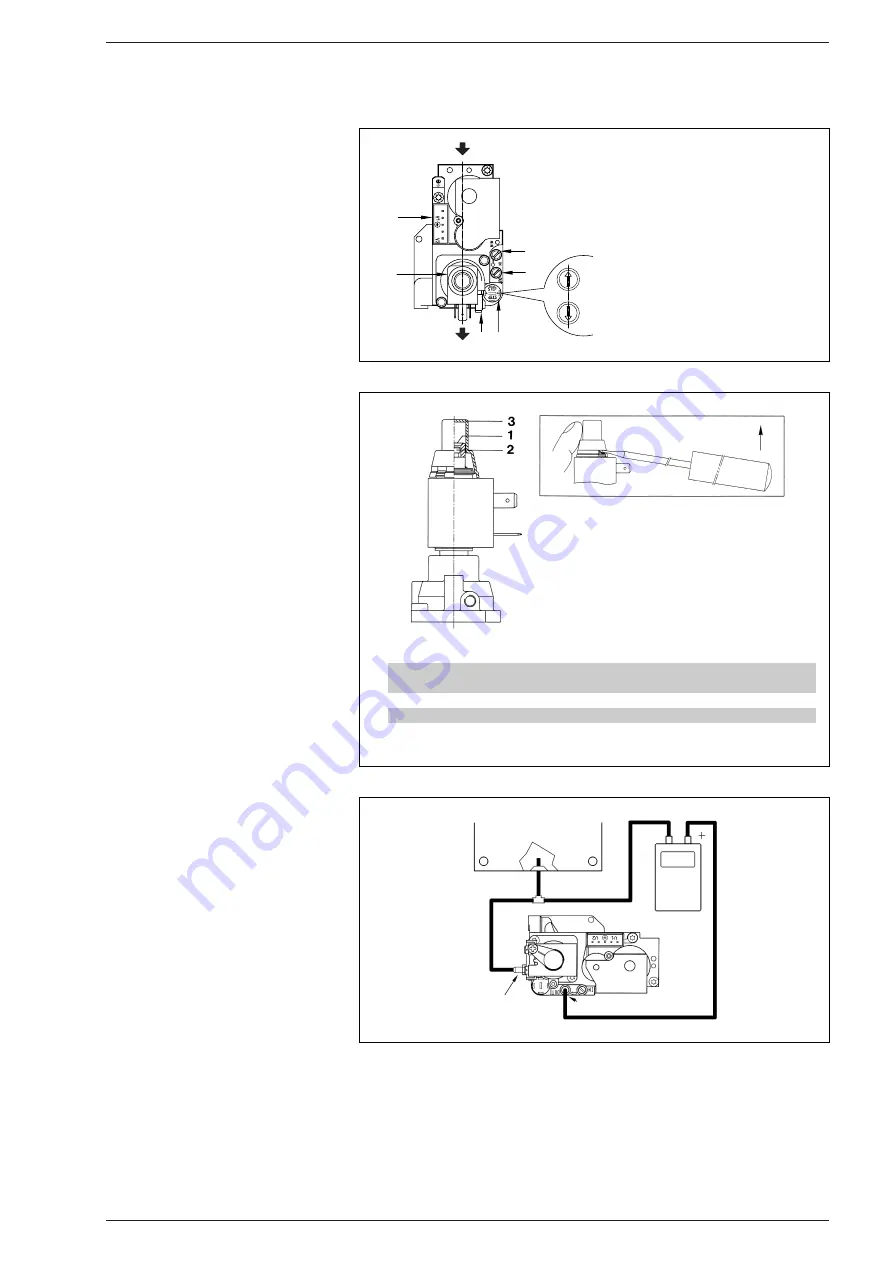

GAS VALVE

(fig. 11)

The boilers are equipped standard with the

HONEYWELL VK 4105Q gas valve.

Gas pressure calibration is carried out by

SIME on the production line and foresees

the minimum C.H.output at 23,2 kW and

the maximum C.H.output at 31,0 kW.

If the pressures are checked only at the

burner, connect the pressure gauge as indi-

cated in fig. 12. If corrections are required

refer to section 4.3.1.

4.3

GAS CONVERSION

This operation must be performed by

authorised personnel using original Sime

components.

To convert from natural gas to LPG or vice

versa, perform the following operations:

– Close the gas cock.

– Replace the principal nozzles and the ø

10 aluminium washers included in kit

(use a 12 wrench in order to carry out

this operation).

–

At start-up change the starting pres-

sure (STEP) of the gas valve by posi-

tioning the index of the screw accord-

ing to the type of gas, as mentioned in

fig. 11.

– To set the values of maximum and mini-

mum gas pressure, follow the instruc-

tions given in section 4.3.1.

Seal the regulators after the operating

pressure values have been changed.

– After have ultimated the conversion of

the boiler, please stick onto the casing

panel the plate showing the relevant

feeding gas which is included into the kit.

NOTE: When reassembling components

which you have removed, replace gas

seals; test all gas connections after

assembly using soapy water or a product

made specifically for the purpose, being

sure not to use open flame.

4.3.1

Adjusting valve pressures

For maximum and minimum pressure cali-

bration follow the procedure listed below

(fig. 11/a):

– Connect the column or a manometer to

the intake downstream of the gas valve

(4 fig. 11).

–

Disconnect the valve VENT pressure test

point tube (5 fig. 11).

– Remove the cap (3) from the modulator.

– Place the boiler stat knob at the maxi-

mum position.

– Turn on the boiler.

– Remember that rotating clockwise will

increase pressure while rotating anti-

clockwise will diminish it.

– Check the gas inlet pressure at the rele-

vant pressure test point (3 fig. 11) with

the boiler running at the maximum output.

– Regulate the maximum pressure by turn-

ing the nut with a fixed wrench (1)

searching for the maximum pressure

Table 3

, or, for the natural gas (G20), if

44

4

USE AND MAINTENANCE

KEY

1

Maximum pressure adjusting nut

2

Minimum pressure adjusting screw

3

Plastic cap

Fig. 11/a

2

1

3

5

4

6

G20

G30-G31

Fig. 11

KEY

1

Modulator

2

EV1-EV2 coils

3

Pressure inlet upstream

4

Pressure inlet downstream

5

VENT pressure test point

6

STEP

Fig. 12

TABLE 3

Type of gas

Burner max. pressure

Burner min. pressure

mbar

mbar

Methane (G20)

12,0

7,1

Butane (G30)

28,1

17,8

Propane (G31)

35,9

17,8

SEALED CHAMBER

VENT PRESSURE TEST POINT

PRESSURE INLET DOWNSTREAM

MANOMETER