36

Handler I, II & III Operator’s Manual - October 2008

Troubleshooting

The Focus Industries Inc. Handler is a simple eduction system

that employs a venturi suction system to place product into

your sprayer tank. It is a convenient and reliable system which

requires minimal maintenance.

The following troubleshooting section lists many of the prob-

lems you may encounter. It defines the possible causes and

presents solutions to the problems. If you have a different prob-

lem, even after having read through this troubleshooting section,

please call you local Handler dealer or the factory. Before you

call, please have this Operator’s manual as well as the model

type and operating system you have purchased available for

reference.

Problem

Cause

Solution

Venturi won’t suck

Improper installation of venturi

Check to make sure the venturi has been installed in the

proper direction and ensure that the nozzle of the venturi is

in place.

Improper line size

Check to make sure the discharge line is large enough to ac-

commodate the flow of the mixture. Discharge line should

be no smaller than the size of the fittings that make up the

venturi package (2” or 3” depending on the model).

Obstructions in the lines

Check to see if there are obstructions in the line after the

venturi. This can be done by running a hose directly from

the venturi to the top of the sprayer tank, bypassing all of

the sprayer plumbing.

Venturi will suck, but not when

the lines are hooked to the spray-

er, or your sprayer fills up before

all the product can be sucked from

the Handler.

Improper fittings

If the venturi is sucking properly, check all fittings to make

sure they are not smaller than the hose size being used.

Note that tees and elbows will add back pressure and reduce

the performance of the venturi, so avoid or reduce the use of

these where possible.

Filter

One of the most common causes of back pressure and

reduced venturi performance is the presence of filters in the

fill line at the sprayer. If you insist on having a filter at the

inlet to your sprayer be aware that it will effect the perfor-

mance of your venturi.

Your sprayer inlet is 1 1/2” or

your tank is smaller than 500

gallons

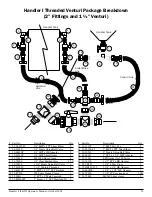

Your Handler must be adapted to 1 1/2” fittings. The easi-

est way to do this is to change the camlock sizes of your

2” Handler to 1 1/2” using reducers and 1 1/2” camlocks.

Simply reducing your hose from 2” to 1 1/2” at the sprayer

will not work.

Jug won’t puncture properly

Dull blade

Resharpen the knife assembly by removing the assembly

and hand sharpening with a file or grinder.

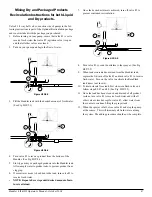

Jug won’t puncture properly, jug

won’t empty

Extra thick jug

Some of the jugs on the market are extra thick. We rec-

ommend puncturing the bottom of any jug off of the thick

reinforced seam. This is the weakest point on the container

and it cuts up the side of the container allowing for full

drainage. See image below for proper puncture location.

Summary of Contents for Handler I

Page 2: ......

Page 48: ...48 Handler I II III Operator s Manual October 2008...