Installation, Operation, & Maintenance Guide

Vantage Series

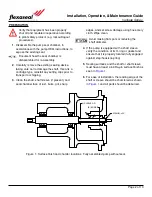

Flexaseal Vantage Series Single Cartridge Seal - Seal Support System Installation

The following briefly describes the methods in which piping should be set up to support Vantage Series single

cartridge seals. The Vantage Series gland is designed to accommodate all API 682 single seal piping plans and

a variety of equipment installation requirements. The gland ports are numbered for reference (

SHEET 1 OF 1

DWG NO:

FS27151-CST-028

SIZE

DRAWN BY:

291 Hurricane Lane

Williston, VT 05495

(802) 878-8307

TITLE:

SURFACE MUST BE CONCENTRIC

PARALLEL, FLAT, SQUARE AND

TRUE AS APPLICABLE TO EACH

OTHER WITHIN .002" TOTAL

INDICATOR READING UNLESS

OTHERWISE SPECIFIED.

DATE:5/15/2020

REV:

1 3/4

A

UNLESS OTHERWISE SPECIFIED

DECIMALS: .005

FRACTIONS: .015

ANGLES: 1/2"

REMOVE ALL BURRS

CHAMFER ALL CORNERS

.010/.020 X 45

A

GLAND

MATERIAL:316 SS / CF8M

DESIGNED BY:

CHECKED BY:

JOB NO.:GEN V

Port 2:

Quench / Vent

Port 1:

Flush

Port 3:

Drain

Port 4:

Flush (Alternate)

Figure 8: Vantage Series Single Cartridge Seal Port Locations

•

Ports 1 and 4 must be plugged if not connected to flush plan piping.

Use thread sealant instead of thread tape. Thread tape has been known to break apart and enter

the seal, resulting in damage to and premature failure of the mechanical seal.

Ensure that all tubing/piping is free of pipe strain, which can adversely affect the seal.

Figure 9: Vantage Series VBRB3 Double Seal Cutaway

Page 5 of 10