Supply air unit VEKA

Integrated Control Equipment Curo

10

Fläkt Woods

9965 GB 2016.09.27

Specifications are subject to alteration without notice

4 Control pAnEl, opErAtionS, CommiSSioning

4.1 gEnErAl

hmi

This section provides an introduction to the touchscreen LCD

control panel, also known as the ‘Human Machine Interface’, or

simply, HMI.

The HMI serves two main purposes: To provide information about

the current operational state of the unit. To allow the unit to be

setup and configured.

touCh SCrEEn tipS

To select an item, touch the center of the icon or option. Do not

press too hard, the touch screen is sensitive enough to pick up

light, firm touches. Use the tip of your finger or the back of a

pencil to touch the required option. Be careful not to touch any

other options.

ClEAning thE SCrEEn

Disconnect the power cord. Gently wipe the screen with a soft,

dry non-abrasive cloth. If the marks remain, moisten the cloth

slightly with a detergent that is de signed for LCD or mobile

screens and wipe the screen gently from top to bottom. Never

use other detergents, as these may contain ammonia or other

additives.

importAnt:

• Never spray, or pour liquids directly on to the screen.

• Do not clean the screen while the system is on.

ConVEntionS uSEd Within thiS mAnuAl

The following buttons and symbols are universal and available on

many menu pages.

Home key, to return to the Home Screen.

Back button, to cancel and return to the previous

page.

Confirm button to confirm and proceed.

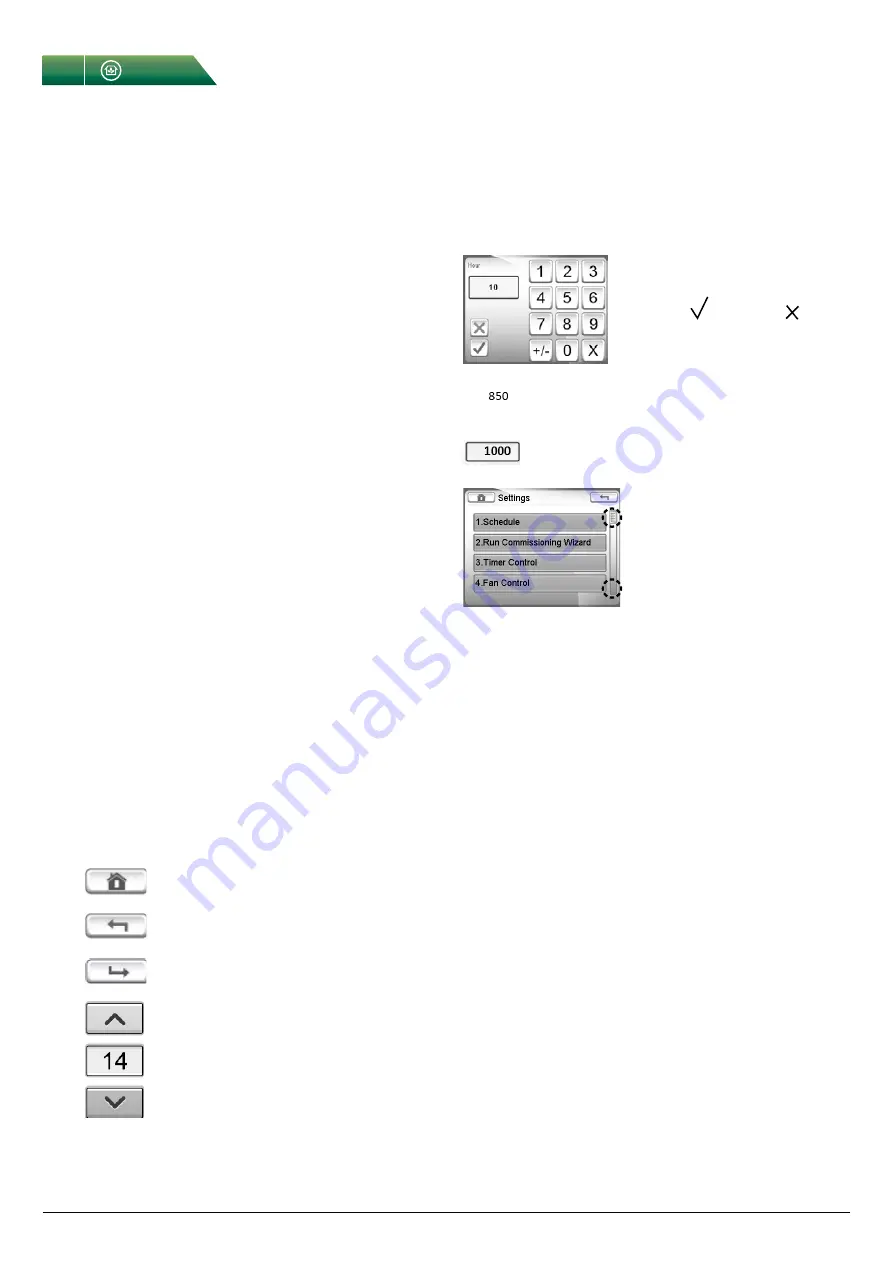

Changing a value:

option 1:

Press the arrow keys to increase or

decrease the value.

option 2:

Press the displayed number to

numerically adjust the value.

uSing thE unit

poWEring on

Each time power is applied, the unit will run through a series of

internal system tests which take approximately 20 seconds to

complete.

Once the internal system tests have been completed, the HMI will

always display the Home screen. The unit will be in Manual Mode

the first time that power is applied.

homE SCrEEn

From the Home screen it is possible to determine how the unit is

operating as well as navigating to further screens to configure the

unit to suit the demands of the end system.

From the Home Screen, it is possible to:

Navigate to further configuration screens to setup system para-

meters.

• Manually adjust the fan speed.

• Determine the operating status of the product.

• Interrogate and acknowledge system alarms.

Use the number buttons to enter

a value.

Confirm with or cancel with .

Values that can only be read, but not written,

are displayed without a surrounding window.

Values that can be both read and written,

are displayed with a surrounding window.

Some submenus has several

pages. Touch the upper or the

lower part of the scroll list to

navigate between pages.