11

10

SPECIALIZED

HEALTHY

AIR SOLUTIONS

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

OWNER’S MANUAL

ASCENDANT

™

ASCENDANT

™

SPECIALIZED

HEALTHY

AIR SOLUTIONS

OWNER’S MANUAL

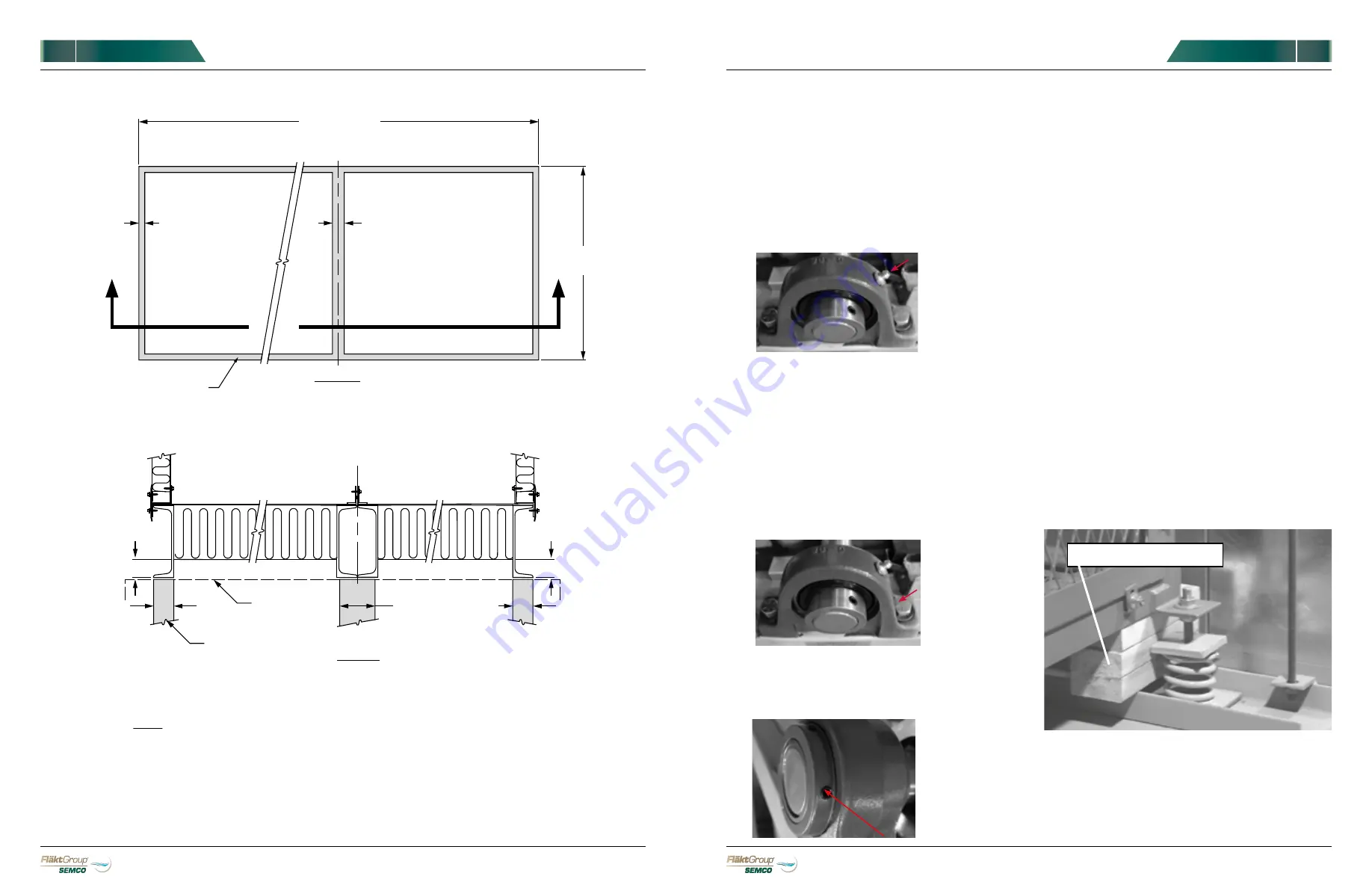

All necessary active desiccant wheel components

have been installed at the factory and tested for

proper operation prior to shipping. Before start up,

the following steps should be taken:

1)

Pump grease into the two rotor bearing grease

fittings using a high quality NLGI No. 2 grease

(See

FIGURE 18

).

ACTIVE DESICCANT WHEEL

FIGURE 21.

Fan shipping restraints located at the base of

the fan.

Remove wooden blocks

All necessary system fans and fan motors are installed

at the FläktGroup SEMCO factory. However, before

attempting to operate them, a pre-startup inspection is

recommended.

1)

Make sure all power to the fan motors is off.

2)

Remove wooden blocks and any shipping

restraints and discard (See

FIGURE 21

).

FANS

FIGURE 18.

Pump

grease into two

rotor bearing

grease points, one

on each side of

the rotor.

FIGURE 20.

The

bearing set

screws, one on

each side of the

rotor, should

be checked for

tightness every

six months.

FIGURE 19.

Inspect bearing

collar to ensure

all bolts and

screws are tight.

2)

Inspect the rotor visually. It should be well

centered in its casing and should not tilt in any

one direction. If alignment is not suitable, contact

FläktGroup SEMCO.

3)

Inspect the bearing bolts and the Allen screws

on the bearing collar to ensure that all are tight

(See

FIGURE 19

). Tighten any loose screws and

bolts. The bearing bolts should be torqued to 50

ft-lbs. The bearing set screws should be torqued

to 15 ft-lbs.

4)

The bearing set screws should be checked

periodically for tightness. A bearing set screw is

located on each side of the rotor (See

FIGURE 20

).

5)

The bearing set screws should be torqued to

15 ft-lbs.

6)

Upon unit startup observe the wheel in operation

and verify that the rotor does not bind. If binding

occurs in a new unit, it is usually caused by the

seal or freight damage.

ADJUSTING THE SEALS

Maintaining correct seal adjustment is vital to the

effective operation of the unit. The face and perimeter

seals are designed to gently contact the face of the

wheel and wheel rim angle to prevent air from leaking

across or around the wheel sections. Adjustment of the

seals is simply done by loosening the screws holding the

seal clips in place, adjusting the seal so it just contacts

the surface of the wheel/rim, and then re-tightening the

screws.

3)

Inspect the fans:

•

Check fan bolts and mountings for tightness.

Tighten loose screws and bolts.

SECTION

UNIT BASE WHEN MOUNTING

ON PAD OR STRUCTURAL GRID

PLAN VIEW

TYPICAL UNIT WITH HOUSEKEEPING PAD

OR STRUCTURAL GRID SUPPORT

UNIT LENGTH

UNIT PERIMETER

UNIT

WIDTH

4"

MINIMUM

SUPPORT AT

FIELD JOINTS

2"

MINIMUM

SUPPORT AT

UNIT PERIMETER

2"

MINIMUM

SUPPORT AT

UNIT PERIMETER

NOTES

1. UNIT SUPPORT IS REQUIRED

AROUND THE ENTIRE

PERIMETER AND ALONG BOTH

SIDES OF ANY FIELD JOINTS.

2. WHEN UNITS REQUIRE FIELD

JOINTS, SUPPORT SHOULD BE

LEVEL TO 1/16" BETWEEN FIELD

JOINTS.

2" WIDE SUPPORT AT

UNIT PERIMETER

FIELD JOINT

CENTERLINE

FIELD

JOINT

CONCRETE PAD

(BY OTHERS)

2"

2"

4" WIDE MINIMUM

SUPPORT AT

FIELD JOINTS

STRUCTURAL GRID

(BY OTHERS)

MOUNTING DETAILS, GRID OR PAD SUPPORT