FL

AIR

MO ApS

–

Lundeborgvej 3

–

DK-9220 Aalborg

–

Denmark

Phone: +45 53717220 Web: www.flairmo.dk - E-mail: [email protected]

9. Vacuum pump starts and stops more frequently than

usual:

a) Leaks. See point 4f.

10. Vacuum pump does not start at minimum vacuum or

does not stop at stop vacuum:

The following points only apply to units with vacuum gauge:

a) Vacuum switch defective. Replace.

b) Vacuum switch is not adjusted correctly. Adjust correctly.

11. Compressor does not switch on against pressure or

does not switch off at max. pressure:

a) Defective pressure switch. Replace.

Test the non-return valve

·

Once a year.

·

Switch off compressor on the main switch and pull out the plug.

·

Pull the ring at the end of the safety valve (fig. 3).

Warning:

Loud noise!

·

Let pressure fall to 0 bar. The pressure is to be read on the

pressure gauge for receiver pressure.

·

If the compressor is mounted with a TÜV-approved safety

valve, the receiver is emptied by loosening the screw at the

end of the safety valve.

·

Dismount non-return valve from receiver (fig. 4).

·

Disassemble non-return valve and clean it (fig. 5)

·

R

e-assemble and mount the non-return valve again

(fig. 4).

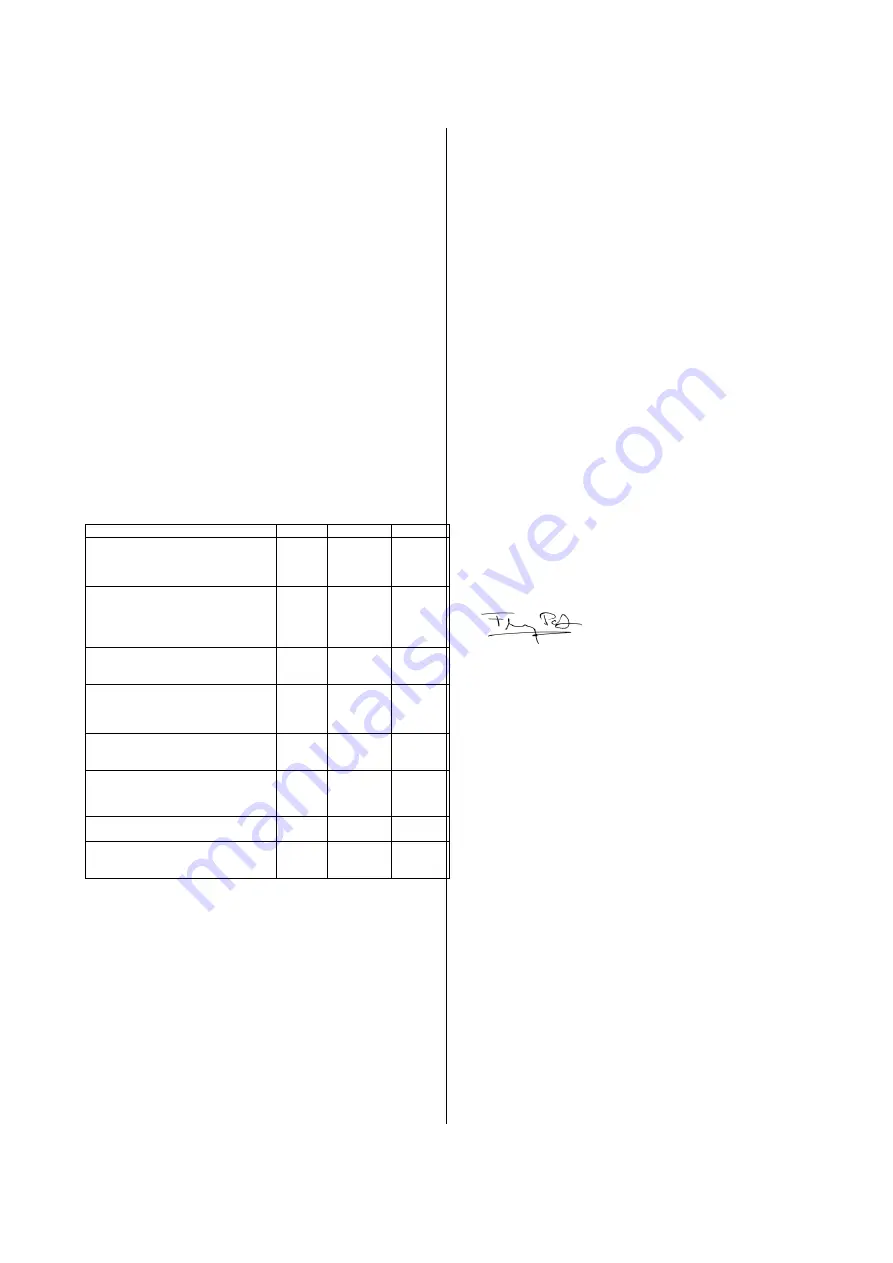

Preventive maintenance (all)

Weekly

Monthly

Annually

Drain condensate from air receiver.

If equipped with autodrain, this will

take place automatically, however,

drain bottle has to be emptied.

x

If compressor is fitted with outlet

filter, check and empty for water

by pressing the black button at the

bottom. If fitted with autodrain, this

will take place automatically.

x

Check motor, air tubes, hoses and

equipment for leaks, and check the

pumping time.

x

Clean unit or wipe with a soft, damp

cloth. If necessary, use paraffin on

rag to remove sticky adhesions.

Dust and dirt prevent cooling.

x

Check intake filter. Clean or replace

if necessary. Min. annually or every

2000 hours whichever comes first.

x

Check the O-ring in the non-return

valve and replace, if necessary.

Note! Empty receiver of air before

dismounting.

x

Check filter and filter elements for

optimum efficiency.

x

Test the safety valve by gently

pulling the ring with pressure in the

receiver.

x

Check the pumping time (Comp.)

The pumping time indicates the condition of the compressor

provided that there are no leaks in the system where the

compressed air may leak. Test the compressor as follows:

1. Empty the air receiver of compressed air (the pressure

gauge shows 0 bar).

2. Close the outlet on the air receiver and check that the drain

cock is closed.

3. Start the compressor and note how long it takes until it

switches off.

Ensure that the pressure in the air receiver is 8 bar/120 psi

as deviations may indicate the wrong results.

Pump up time for this compressor is approx. 60sek.

Important!

Always test the compressor when cold as the time

indicated refers to the pumping time of a cold

compressor. The pumping time of a warm compressor

is much longer and consequently, the result would be

misleading.

Pressure vessel

Directions for use

Application: Receiver for compressed air.

Receiver specifications: See name plate.

Installation: Tubes, etc. must be made of suitable materials.

Placement: Observe the working temperature of the receiver.

Ensure that sufficient room for inspection/maintenance is

available in a horizontal position.

The receiver must be kept in a horizontal position..

Corrosion protection The surface treatment must be maintained

as required.

Internal inspection at least every 5 years.

Drain moisture at least once a week.

Alternation/repair No welding must be made on pressurized parts..

Safety valve Ensures that PS will not be exceeded.

Never adjust to a higher pressure than PS.

The capacity of the valve must be calculated in accordance

with the volume of air supplied by the compressor.

(PS = Maximum working pressure of the receiver)

Declaration of Conformity

NOTE: The declaration of conformity is only valid for units

operating at 230 V/50 Hz, 3x400 V/50 Hz, 12 V DC or 24 V DC.

The manufacturer, FLAIRMO ApS, declares that the products

mentioned in this manual are in conformity with:

• 87/404/EEC - 90/488/EEC - 93/68/EEC Council Directive

relating to Simple Pressure Vessels

• 98/37/EC Machinery Directive

• 89/336/EEC EMC Directive

• 73/23/EEC Low Voltage Directive

Flemming Steen Petersen

Teknisk Direktør