Lit. No. 94196/94197/94198, Rev. 05

19

November 1, 2010

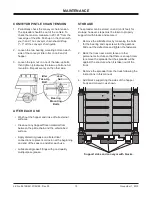

CONVEYOR PINTLE CHAIN TENSION

1. Periodically check the conveyor chain tension.

The spreader should be out of the vehicle. To

check the tension, measure in 20"–24" from the

rear edge of the sills. Push up on the chain with

your hand. The conveyor chain should lift up

1"–3" off the conveyor chain guide.

2. Loosen the two bearing mounting bolts on each

side of the conveyor idle roller on cab end of

hopper.

3. Loosen the jam nut on one of the take-up bolts,

then tighten (clockwise) the take-up bolt one full

revolution. Repeat evenly on the other side.

AFTER EACH USE

• Wash out the hopper and rinse off all external

surfaces.

• Clean out any trapped/frozen material from

between the pintle chain and the vehicle bed

surface.

• Apply dielectric grease on all electrical

connections to prevent corrosion at the beginning

and end of the season and after each use.

• Lubricate all grease

fi

ttings with good quality

multipurpose grease.

MAINTENANCE

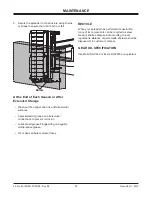

STORAGE

The spreader can be stored on end (on its feet) for

storage; however, steps must be taken to properly

support it with blocks and secure it.

1. Remove the sill de

fl

ectors by loosening the bolts

for the bearing and cap screws for the gearbox.

Slide out the de

fl

ectors and tighten the fasteners.

2. Back the truck near a wall, fence or other

permanent structure so that there is enough room

to remove the spreader but the spreader will be

against the structure when it is taken out of the

truck.

3. Remove the spreader from the truck following the

instructions in this manual.

4. Add blocks supporting the sides of the hopper

body and conveyor, as shown.

Jam

Nut

Idler

Take-Up

Bolt

Bearing

Mounting

Bolts

Support sides and conveyor with blocks.