51

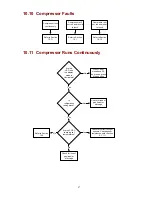

Air ducts

blocked with

ice?

Adjust temperature

settings.

Advise customer

product OK

Does the

display

module

indicate a

fault code?

Are sensors

and covers

installed

correctly?

Is Smart Tool

download

available?

Refer to Section

6.2.1

Repair or replace

faulty components

Are

temperature

settings

correct?

Check door gasket

sealing is OK

Install components

correctly, sealing

any air leaks

No

Yes

Yes

Yes

No

No

Yes

Do download

temperatures and

actual contents

temperatures

match?

No

No

Clear ice & check

for causes

Yes

Yes

No

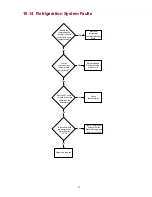

10.4 FC Too Cold – PC Too Warm

Summary of Contents for 790 Active Smart

Page 1: ...790 ACTIVE SMART REFRIGERATOR FREEZER 517800...

Page 2: ...2...

Page 42: ...42 8 WIRING DIAGRAM...