10

©Firefly AB (Oktober 2016)

This option provides the user with a method of programming the

unit number into the non- volatile memory of the microprocessor .To

program the detector address number, first remove power from the

detector . Then toggle the program option “ON” and set the first five

switches on the user selectable interface (USI) to the detector address

number .

In program mode, the USI becomes a binary programmer as illustrated

in Table 6 . When a switch is toggled “ON”, it will equal the binary

weighted number . These binary weighted numbers are added

together when a multiple number of switches are switched “ON” (i .e .,

if SW2 and SW3 were closed, then the detector number would equal

a 6) .

Table 6 Binary Weight for Switch States “ON”

SW1

SW2

SW3

SW4

SW5

1

2

4

8

16

When power is applied to the detector . The detector will sense that

it is in program mode and read the first five switch positions . From

the switch setting, it will determine the detector number . Once the

number has been determined, the detector will enter it into the non-

volatile memory of the microprocessor . Next, the amber LED will flash

“ON” a certain number of times . The number of flashes will be equal

to the detector’s address number . Then it will hold the fault relay and

amber LED “ON” constantly for about 10 seconds . Then the detector

will repeat flashing the detector address number and the delay time . It

will continue this mode for up to 5 minutes .

Once you are sure that the proper number is programmed, then shut

the power “OFF” and set the USI options to suit your application .

Reference the section on the USI if you are not sure which option is

best for your application or call a Firefly AB application engineer .

Note:

In the case that the program option switch is left “ON” and the

detector is installed on the network . The detector will go through the

same process as explained previously, but after 5 minutes the detector

will resume the last USI setting that it had prior to going into the

program mode .

Maintenance and troubleshooting

Model 660 and 860 flame detectors are designed for years of

trouble-free operation with minimal attention . Periodic cleaning of

the optical surfaces is essential, however, for maintaining reliable fire

protection . The frequency of required cleaning will be determined

by the environmental conditions in and around the installation . The

detectors should be regularly inspected for a build-up of dust or other

contaminants on the optical surfaces .

The detection specifications presented in this manual are predicated

on performance with clean sensor windows . Contaminants such as

dust, oil and paint will reduce sensitivity . Severe contamination on the

light guides or sensor windows will cause a failure of the auto-test .

A detector that fails auto-test due to dirty optical surfaces may be

capable of detecting fire, but its effectiveness will be limited from 50 to

70% obscuration .

Cleaning Procedure:

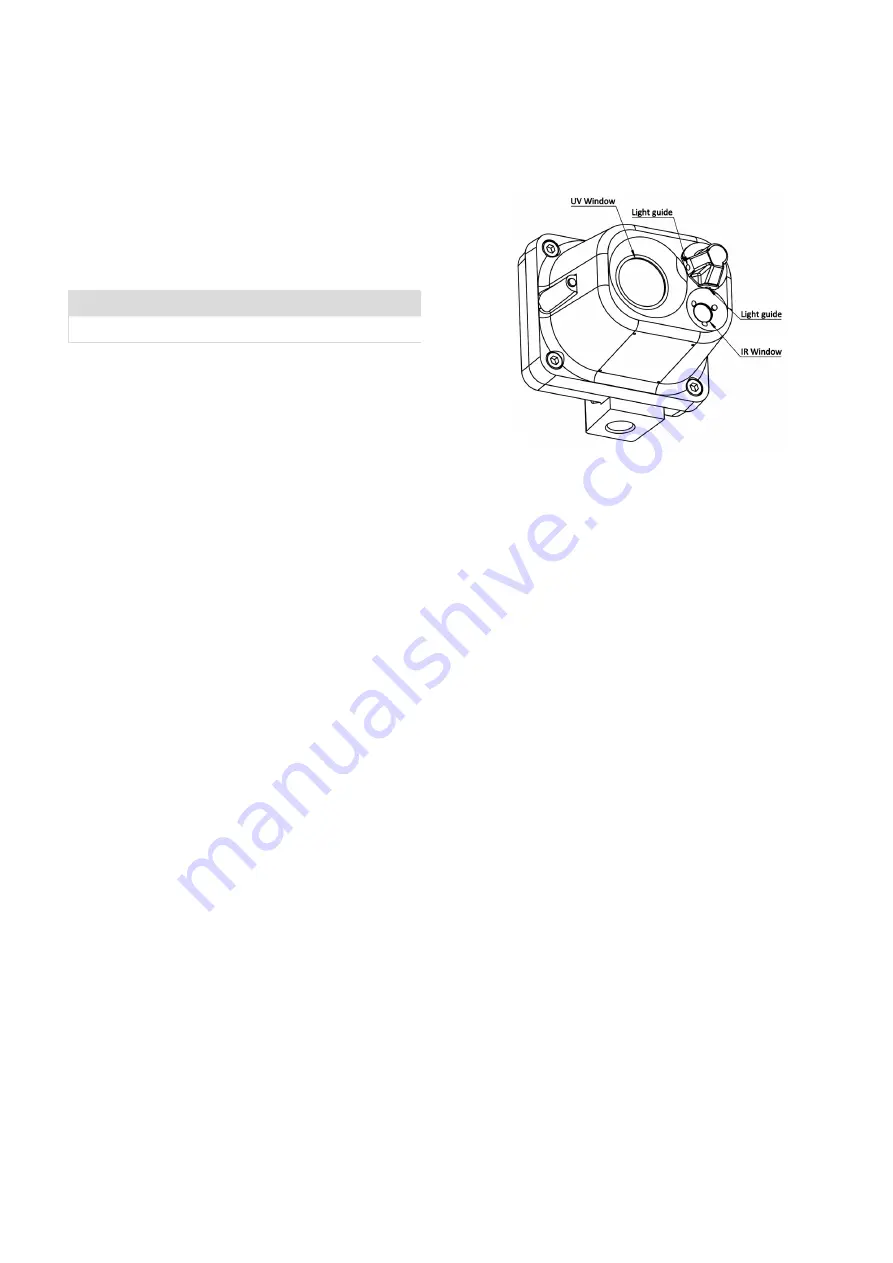

Locate the following optical surfaces: (Figure 11)

Models 660-XX1XX

1 . UV Sensor Window

2 . UV Light Guide End

Model 860-XX1XX

1 . UV Sensor Window

2 . UV Light Guide End

3 . IR Sensor Window

4 . IR Light Guide End

Note:

Models 660-XX0XX and 860-XX0XX are not equipped with light

guides . Clean the optical surfaces with a cotton swab wetted with

commercial liquid glass cleaner, ammonia, methanol, or isopropyl

alcohol . Rinse with clean water and dry with lens quality cloth . Repeat

with methanol if needed to remove smudges .

Caution:

Wiping with excessive force or inappropriate materials may

scratch the optical surfaces and impair performance .

Figure 11 – Optical surfaces

Troubleshooting:

*WARNING*

Do not attempt to repair a detector . Study these

troubleshooting guidelines and review the referenced sections of the

manual prior to performing maintenance on the fire detection system .

New Installations:

Starting with Revision E Software, when the detectors are in

operational mode, and amber LED will be visible for one second

approximately every ten seconds . If any or all the detectors fail to

operate, check the system wiring and power supply . Tight, reliable

wiring connections are essential, as are low-resistance connections

from every detector housing to earth ground . Measure the voltage

between terminals 8 and 10 at the detector locations to verify that the

supply voltage is within range .

Note:

Voltage at detectors installed farthest from power source will be

lower than the no-load supply voltage due to line losses . Maximum

load condition occurs during manual test .

The Model 660 and 860 flame detectors employ sensitive and

sophisticated electronic circuitry in the fire detection process . Power

line transients or excessive power supply ripple may therefore cause

erratic or intermittent operation . DC-powered detectors function best

with ripple-free (less than 1 percent) supply voltage; power supply

filtering may be necessary to improve performance .

Note:

For reliable operation, the instantaneous supply voltage at the

input to any detector must not fall below 20 Vdc or exceed 32 Vdc .

Failure To Alarm:

Upon detection of fire, the fire outputs will activate and the red LED,

visible through the UV sensor window, will turn “ON” .

If during testing, a detector fails to alarm, inspect the sensor windows

for cleanliness . Clean sensor windows are essential for effective

optical fire detection . Clean all the optical surfaces per the cleaning

procedures previously described and retest the detector .

Should the detector continue to be inoperative, check the supply

voltage and all associated wiring . Incorrect power supply voltage or

loose connections will cause marginal or intermittent performance .

DMLieferant

Тел

.: +7 (499) 990-05-50; +7 (800) 775-29-59 dmliefer.ru