START-UP AND OPERATION INSTRUCTIONS

BIG 38/48

5. MAINTENANCE

5.1. ROUTINE MAINTENANCE TABLE

Regular maintenance is essential to keep the floor scrubber-dryer in efficient working order and to extend

its working life for the entire the warranty period. A written record should be kept of all maintenance

operations performed on the form provided in this manual.

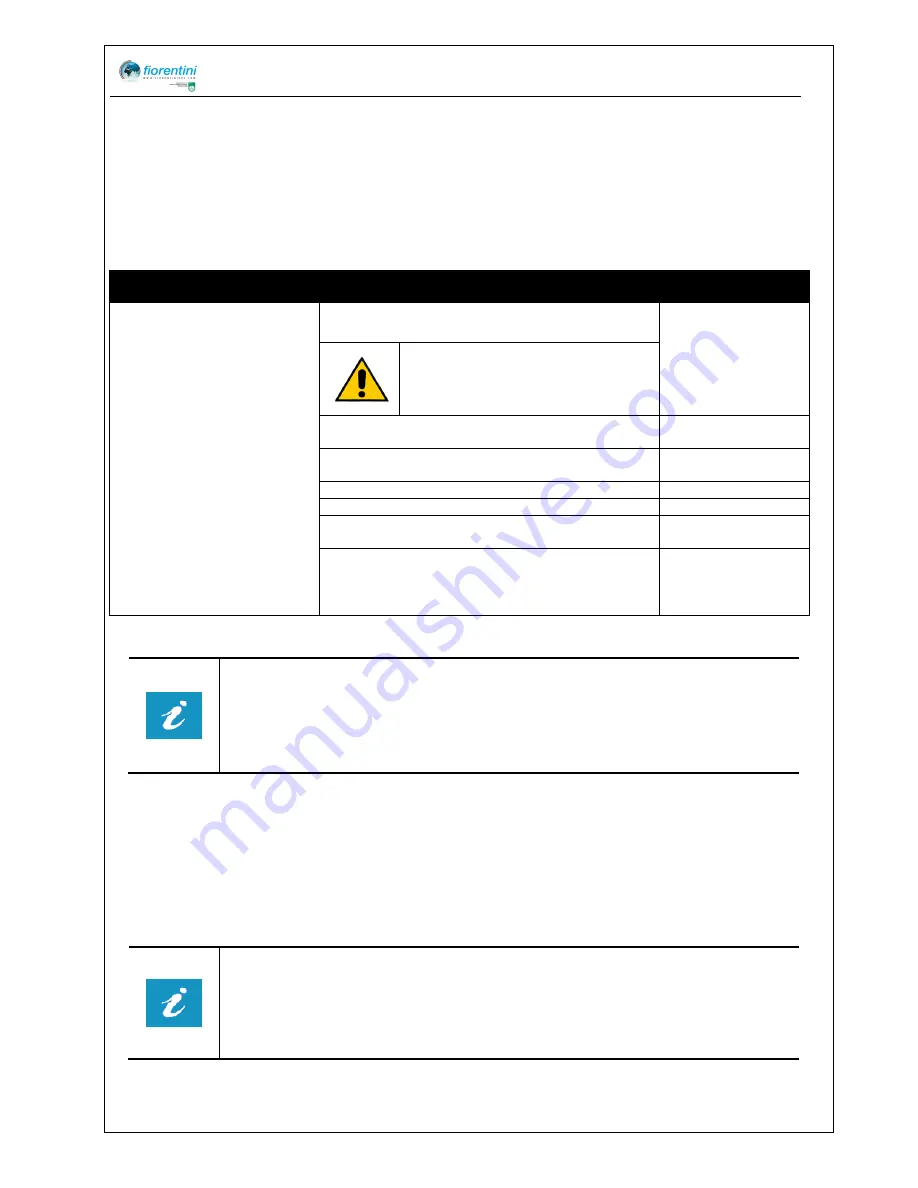

REQUIRED TASK

WORK PROCEDURE

FREQUENCY

Cleaning

–

Checks

-

Replacement

Cleaning the recovery tank and suction motor filter

Daily

Do not use corrosive substances.

Do not use pressurised water

sprays

.

Checking the the suction hoses and

squeegee for dirt

Every week

Checking the condition of the squeegee

suction blades

Every 2 weeks

Checking the filter on the clean water tank

Every month

Checking and adjusting the brake system

Every 3 months

Checking the battery cable connections

Checking the battery water level

Every 6 months

Checking the condition of the brushes on

each motor

Checking the electrical system

Checking the safety devices

Once a year

Carry out all checks, cleaning and replacements with the machine switched off.

Maintenance operations should only be carried by authorised and trained personnel,

particularly with regard to electric and electromechanical parts. Use the proper tools and

equipment for each maintenance task.

Contact Fioerentini S.p.A. exclusively for servicing and spare parts. (point 6.1. / 6.2.).

5.2. BATTERY MAINTENANCE

The operator can check the battery level while the machine is in operation from the indicator on the dashboard.

The indicator provides the following information:

Green: battery fully charged

Yellow: battery partially charged

Red: battery low

Leave the battery compartment open while charging

Do not smoke or use naked flames near batteries

Be careful with battery fluid as it is corrosive

Do not create sparks near batteries

Battery gases are explosive

Do not reverse the battery polarity