MEGA SD - Cod.197DD8100

GB

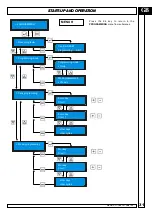

START-Up AND OpERATION

• Time to service

Makes it possible to check the first maintenance operation to be carried out on the compressor; the maintenance operations

to be carried out 100 hours after this are also displayed. In this way, the user can schedule maintenance operations and, if

necessary, decide whether to replace several components during the same maintenance operation.

• Components life

Indicates the remaining service life of each component that requires periodic maintenance.

• Compon. replacement

If the function is enabled, it makes it possible to reset the component life counters after maintenance.

• running hours

Indicates compressor operating time (total running hours, running hours at full Ioad).

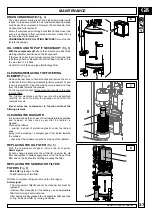

• A table with the schedule of the maintenance operations to be carried out is provided below.

Maintenance periods may differ from those indicated.

During installation, Service Centre personnel assesses compressor operating conditions and if necessary modify the frequency

of the operations.

4.2.3 GENErAL SETTINGS MENU

This menu allows to carry out the general settings of compressor operating configuration with the exception of operating

parameters (pressures, timings).

• Language

used to select the language of the messages.

• Measur. unit

used to set the measurement units for pressure and temperature.

• Date & time

used to set the current date and time.

The time and date are entered using:

the K7 and K8 keys to modify the flashing values.

the K5 and K6 keys to move to modification of the previous / next character.

After entry of the values, these can be confirmed with the K9-ENTER key

or cancelled with the K4-ESC key.

• Display settings

Makes it possible to adjust the settings of the LCD display.

• Operating mode

Compressor operating mode may be set AuTOMATIC or CONTINuOuS:

AUTOMATIC:

this is the setting used in most cases (factory setting). In this operating mode, idling is timed; at the end of the

count, the compressor stops, preparing for subsequent automatic start-up (see also paragraph 7.3 STARTING the compressor).

This promotes energy saving if there is no or a very low request for compressed air.

CONTINUOUS:

this setting should be used in very particular applications characterized by a considerable variation in

compressed air consumption combined with a reduced plant accumulation capacity. with this setting, the compressor starts

unload run without ever stopping the motor and is therefore able to supply air continuously in the case of a request from the

network. The system configured in this way is highly reactive. however, one of the drawbacks of this operating mode is that

it entails higher power consumption due to the fact that the compressor is always running (see also paragraph 3 STARTING

the compressor).