11

Installation Instructions

Equipment Setup

1. Read User Guide noting all instructions. Review the dimensions for the unit you are installing.

Verify that it will fit in the space intended for it.

Verify that the counter or table will support the total weight of the equipment and any dispensers when filled.

2. Place the equipment on the counter or stand.

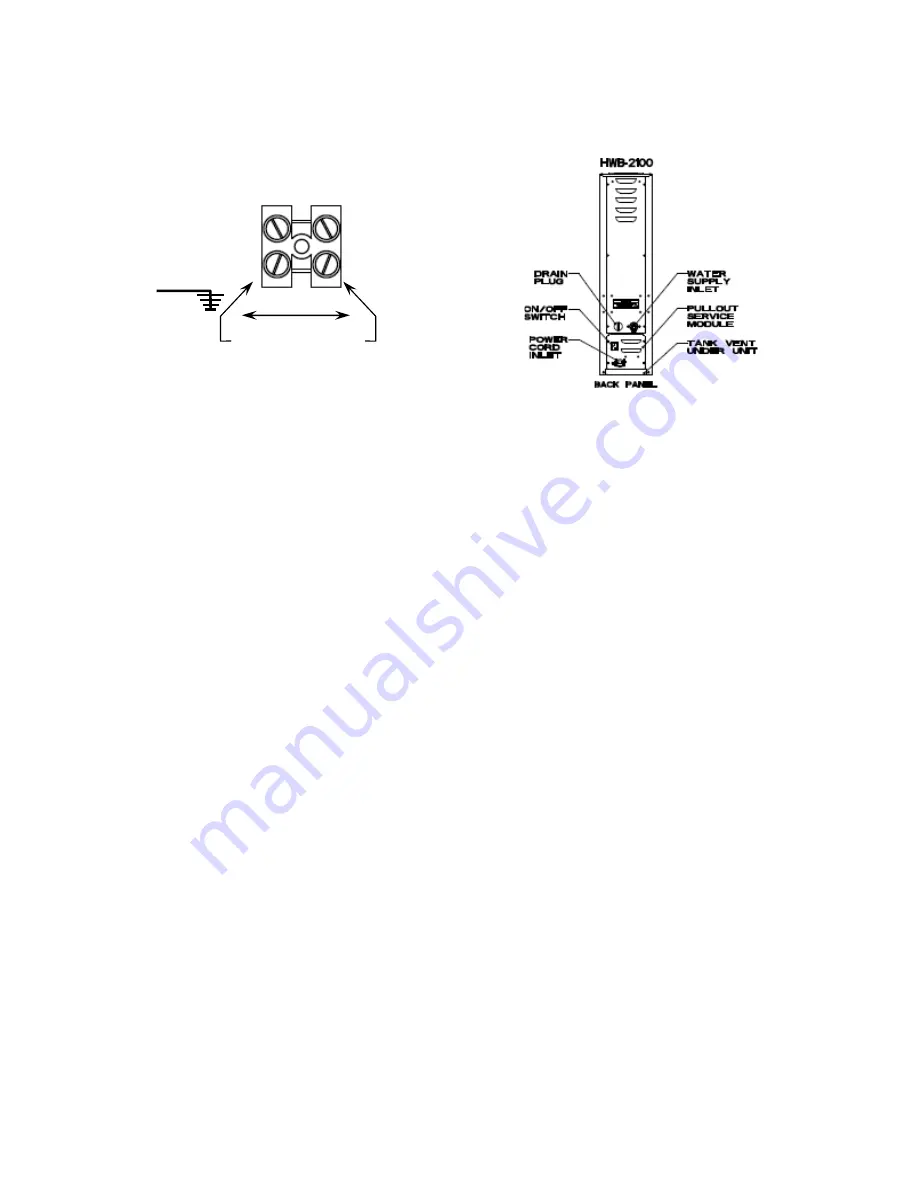

Illustrations above show examples of domesic terminal block and location of connections and utilities.

Æ

Always refer to the wiring diagrams when connecting equipment electrical utilities

Water Connection

1. Water supply inlet is a

⅜

inch male flare fitting.

2. The Hwb-2100 Hot Water Dispenser can be connected to a cold or hot water line.

(Cold water is preferred for best beverage flavor, but hot water will allow for greater output.)

3. Install a shut off water valve near the equipment to facilitate service. An in-line water filter should used and

installed after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter

before

connecting it to the unit.

5. Verify that the water line will deliver a flow rate of at least 1½gpm/(5.7lpm) per minute and water pressure is

between 20-75 psig (138-517kPa) before making any connections.

6. Use a wrench on the factory fitting when connecting the incoming water line. This will reduce stress on the

internal connections and reduce the possibility of leaks developing after the install has been completed.

Electrical Connection

1. The HWB-2100 model series requires hardwired grounded service to the terminal block (illus. 1)

2. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

equipment serial number label. Make sure the electrical service match the current draw of the equipment.

3. Access the terminal block for electrical connection by removing the pullout service module on the lower back.

4. A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near the

equipment and its location and markings known to the operators.

5. The body of the unit must be grounded to a suitable building ground.

6. If Cord Connected: Do not use multiple taps for the plug. Consult local codes to determine if a single circuit is

required for the cord and plug installed. Do not use extension cords for commercial food equipment

Tank Drain

The water tank must be drained before maintenance procedures, and when the unit is to be relocated or shipped.

1. Disconnect power to the unit.

2. Move the unit near a sink or obtain a container to large enough to hold four gallons of water.

3. Remove the tank cover and allow the tank to cool to a safe temperature.

4. The tank drain is located on the back of the unit. Turn the drain plug one-quarter turn in either direction.

5. Pull the plug out far enough to expose the silicone tube.

6. Using pliers loosen the hose clamp and move it back over the tube.

7. Crimp the tube an inch or two away from the drain plug to prevent water from flowing.

8. Use the other hand to pull the drain plug out of the tube.

9. Release the crimped tube and allow the water to flow into the sink or container.

200-240V ac, 50-60Hz

North America

Domestic

GROUND

L1 L2

Summary of Contents for HWB-2105 XTS

Page 3: ...3 Dimensions Utility Connections HWB 2105 DRG 1201 00015 00 HWB 2110 DRG 1201 00016 00...

Page 14: ...14 Parts and Service drawings Drawing 1101 00201 229 217 00 HWB 2105 Complete Parts...

Page 16: ...16 HWB 2110 Complete Parts Drawing 1101 00202 00...

Page 18: ...18 HWB 2105 Hot Water Tank Drawing 1104 00072 78...

Page 20: ...20...

Page 24: ......

Page 25: ......