3. Installation

3-4

Festo P.BE-CDVI-EN en 1202e

3.1

Compressed air preparation

Note

Unfiltered or incorrectly lubricated compressed air will

reduce the service life of the valve terminal.

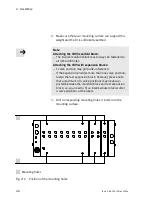

3.1.1 Operation with unlubricated compressed air

Note

Too much residual oil content in the compressed air will

reduce the service life of the valve terminal.

– If bio oils are used (oils based on synthetic esters or nat-

ive esters, e.g. rapeseed oil methylic ester), the residual

oil content must not exceed max. 0.1 mg/m

3

(see ISO

8573-1 class 2).

– If mineral oils are used (e.g. HLP oils to DIN 51524 Part 1

to 3) or corresponding oils based on polyalphaolefin

(PAO), the residual oil content must not exceed 5 mg/m

3

(see ISO 8573-1 class 4).

This avoids operative malfunction of the valves.

Excessive residual oil is not permissible irrespective of the

compressor oil, as otherwise the basic lubrication will be

washed out with time.

Summary of Contents for CDVI-DN

Page 2: ......

Page 4: ...Contents and general safety instructions II Festo P BE CDVI EN en 1202e...

Page 15: ...Overview of components 1 1 Festo P BE CDVI EN en 1202e Chapter 1 Overview of components...

Page 31: ...Assembly 2 1 Festo P BE CDVI EN en 1202e Chapter 2 Assembly...

Page 39: ...Installation 3 1 Festo P BE CDVI EN en 1202e Chapter 3 Installation...

Page 63: ...Commissioning 4 1 Festo P BE CDVI EN en 1202e Chapter 4 Commissioning...

Page 100: ...5 Cleaning maintenance and conversion 5 26 Festo P BE CDVI EN en 1202e...

Page 101: ...Technical appendix A 1 Festo P BE CDVI EN en 1202e Appendix A Technical appendix...

Page 109: ...A Technical appendix A 9 Festo P BE CDVI EN en 1202e A 2 Accessories www festo com catalogue...

Page 114: ...A Technical appendix A 14 Festo P BE CDVI EN en 1202e...

Page 115: ...Index B 1 Festo P BE CDVI EN en 1202e Appendix B Index...

Page 116: ...B Index B 2 Festo P BE CDVI EN en 1202e Contents B Index B 1...