ECONCEPT ST

40

EN

cod. 3540S814 -

/201

(Rev. 00)

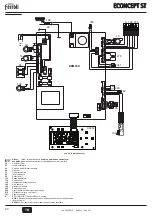

3.7 Condensate drain connection

The boiler is equipped with an internal trap to drain condensate. Fit the inspection union

A

and hose

B

, pressing it in for approx. 3 cm and securing it with a clamp. Fill the trap

with approx. 0.5 l. of water and connect the hose to the drainage system.

fig. 24 - Condensate drain connection

4. SERVICE AND MAINTENANCE

All adjustment, conversion, commissioning and maintenance operations described be-

low must only be carried out by Qualified Personnel (meeting the professional technical

requirements prescribed by current regulations) such as those of the Local After-Sales

Technical Service.

FERROLI

declines any liability for damage and/or injury caused by unqualified and un-

authorised persons tampering with the unit.

4.1 Adjustments

Gas conversion

The unit can operate on Natural Gas or LPG and is factory-set for use with one of these

two gases, as clearly shown on the packing and on the dataplate. Whenever a different

gas to that for which the unit is arranged has to be used, a conversion kit will be required,

proceeding as follows:

1.

Remove the casing.

2.

Open the sealed chamber.

3.

Replace the nozzle

A

inserted in the mixer, with that contained in the conversion kit.

4.

Reassemble and check the tightness of the connection.

5.

Apply the label, contained in the conversion kit, near the dataplate.

6.

Refit the sealed chamber and casing.

7.

Modify the parameter for the type of gas:

•

put the boiler in standby mode

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds. the display

shows "

P01

" flashing.

•

press the DHW buttons (details 1 and 2 - fig. 1) to set parameter

00

(for natural

gas) or

01

(for LPG).

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds.

•

the boiler will return to standby mode

8.

Check the working pressure.

9.

Using a combustion analyser connected to the boiler fume outlet, check that the

CO

2

content in the fumes, with the boiler operating at max. and min. output, corre-

sponds to that given in the technical data table for the corresponding type of gas.

fig. 25 - Gas nozzle replacement

TEST mode activation

Press the heating buttons (details fig. 13 and 4 - ) together for 5 seconds to activate the

TEST

mode. The boiler lights at the maximum heating power set as described in the fol-

lowing section.

The heating symbol (detail 24 - fig. 1) and DHW symbol (detail 12 - fig. 1) flash on the

display; the heating power and actual flame current value (uA x 10) will be displayed

alongside.

fig. 26 - TEST mode (heating power = 100%)

Press the heating buttons (details 3 and 4 - fig. 1) to increase or decrease the power

(min.=0%, max.=100%).

Press the DHW button

"-"

(detail 1 - fig. 1) and boiler power is immediately adjusted to

min. (0%). Press the DHW button

"+"

(detail 2 - fig. 1) and boiler power is immediately

adjusted to max. (100%).

If the TEST mode is activated and enough hot water is drawn to activate the DHW mode,

the boiler remains in TEST mode but the 3-way valve goes to DHW.

To deactivate the TEST mode, repeat the activation sequence.

The TEST mode is automatically disabled in any case after 15 minutes or on stopping of

hot water drawing (in case of drawing of hot water enough to activate DHW mode).

Heating power adjustment

To adjust the heating power, switch the boiler to TESTsec. 4.1 mode (see ). Press the

heating buttons

(details 3 and 4 -

) to fig. 1increase or decrease the power (min. = 00

- max. = 100). Press the

RESET

button within 5 seconds and the max. power will remain

that just set. Exit TEST

mode (

see sec. 4.1).

4.2 System start-up

B

Checks to be made at first ignition, and after all maintenance operations that

involved disconnecting from the systems or an intervention on safety devices

or parts of the boiler:

Before lighting the boiler

•

Open any on-off valves between the boiler and the systems.

•

Check the tightness of the gas system, proceeding with caution and using a soap

and water solution to detect any leaks in connections.

•

Check the correct preloading of the expansion tank (ref. sec. 5.3)

•

Fill the water system and make sure that all air contained in the boiler and the sys-

tem has been vented by opening the air vent valve on the boiler and any vent valves

on the system.

•

Make sure there are no water leaks in the system, hot water circuits, connections or

boiler.

•

Check the correct connection of the electric system and the functioning of the earth

system. l

•

Check that the gas pressure value for heating is as required.

•

Make sure there are no flammable liquids or materials in the immediate vicinity of

the boiler

Checks during operation

•

Ignite the appliance as described in sec. 2.3.

•

Check the airtightness of the fuel circuit and water systems.

•

Check the efficiency of the flue and air-fume ducts while the boiler is working.

•

Check that the water is circulating properly between the boiler and the systems.

•

Make sure that the gas valve modulates correctly in both the heating and hot water

production phases.

•

Check the proper ignition of the boiler by performing various tests, turning it on and

off with the room thermostat or remote control.

•

Make sure that the fuel consumption indicated on the meter corresponds to that giv-

en in the technical data table in sec. 5.3.

•

Make sure that with no call for heating the burner correctly ignites on opening a hot

water tap. Check that during heating operation, on opening a hot water tap, the heat-

ing circulator stops and there is a regular production of hot water.

•

Check the parameters are programmed correctly and perform any required custom-

ization (compensation curve, power, temperatures, etc.)

A

eco

comfort

m

o

d

e

r e s et

eco

bar