6

NOTE: CHOOSE WHICH SIMULATION TO USE

During simulation with feedback, the movement speed of the transplanting bodies is controlled by

the rotary encoder that detects the speed of the transmission shaft. This simulation can be useful

for observing the movement mode and speed of the transplanting bodies at different travel speeds.

It can also be useful for diagnosing any faults in the rotary encoder of the transmission shaft (or its

wiring): if the signal is not detected correctly, the system does not control the speed correctly. In

this case, if the alarms are enabled, the relative alarm will be shown.

During simulation without feedback, the proportional valve that controls the speed of the

transmission shaft is excited with a constant voltage that can be set. Encoder signals are not used

in any way. This simulation can be useful for evaluating actual operation of the hydraulic motor, the

proportional valve, the hydraulic system and the mechanical system. Furthermore, this mode can

be useful for diagnosing any mechanical hardenings as well as if rotation is sufficiently constant.

None of these two simulations engage the rotary encoder mounted on the wheel (or on the roller)

that detects the travel speed.

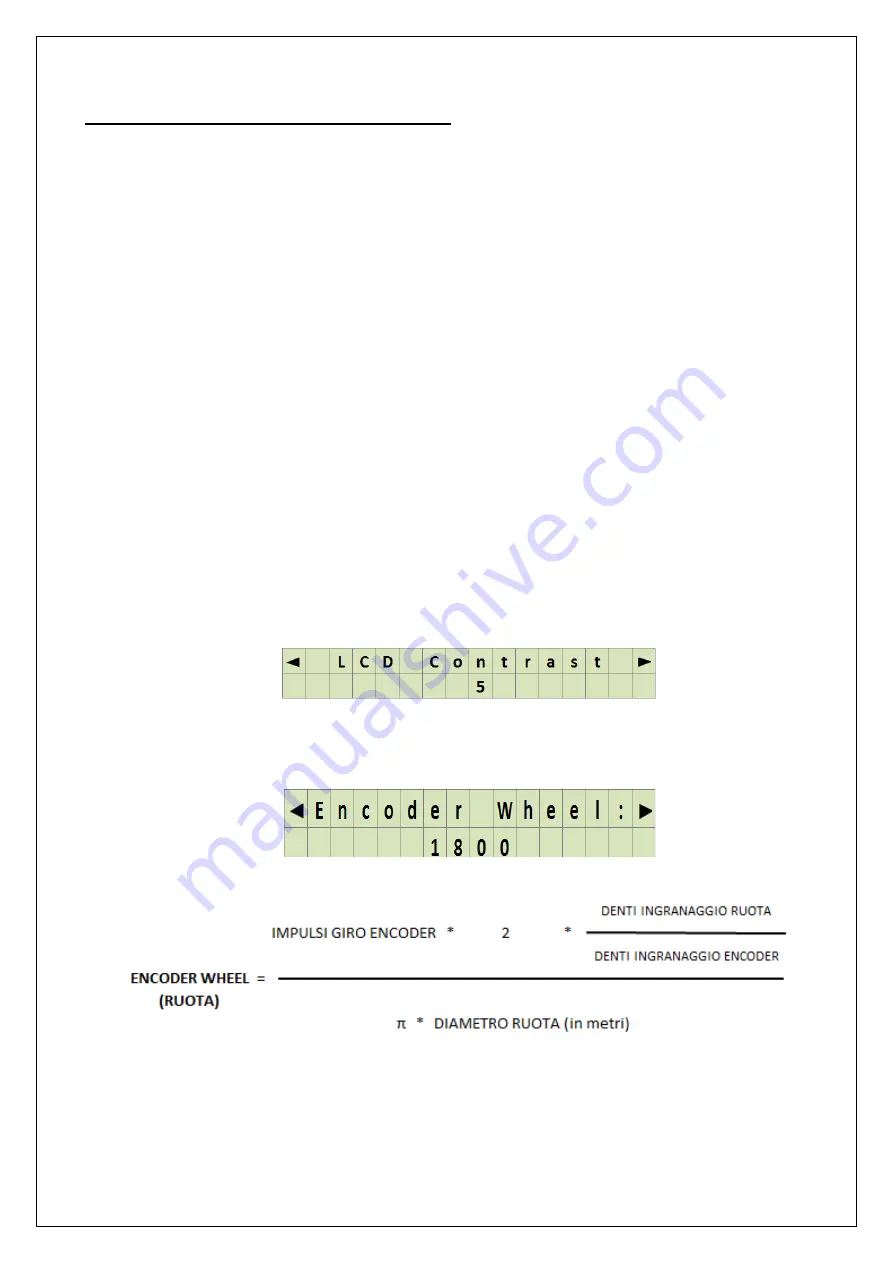

LCD screen contrast (LCD Contrast)

Indicates the LCD screen contrast value: the reference value goes from a minimum of 0 to a

maximum of 10. The higher the value, the higher the contrast.

Number of wheel encoder pulses per metre (Encoder Wheel)

Indicates the number of wheel encoder pulses corresponding to one metre travelled by the machine.

This parameter is calculated with the following formula:

Multiplication by 2 is due to the 2 encoder phases. If there are other transmission ratios between

the wheel gear and the encoder gear, these must be taken into account when calculating the

parameter.