FALCON II

27

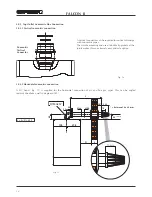

7.06 Air pressure switch

(fig. 27)

• Isolate electricity

• Remove outer case (two screws bottom rear corners)

• Open room sealed department

• Remove the two screw "A" fixing air pressure switch

• Disconnect electrical leads "B"

• Remove pressure sensing tubes (white=D; Red=C)

• Note relevant positions of all connections and

replace in reverse order.

Fig. 27

Fig. 28

7.05 Gas valve

(fig. 26)

• Isolate gas and electricity supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Disconnect electrical connections

from valve ("A")

• Disconnect plastic tube "C"

• Loosen the connection "D" on gas pipe and the gas

inlet connection of the boiler "E"

• Remove the two fixing screw "E" below gas valve

• Slide out gas valve

• Remove four fixing screw "F" on top of

the valve and disconnect the gas pipe

• Remove bottom connection from gas valve.

• Fit top + bottom gas connections to the

new gas valve and replace in reverse order

C.H. sensor

Water pressure switch

D.H.W. sensor

Safety valve

A

B

C

D

D

C

A

F

E

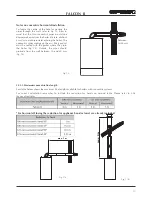

7.07 D.H.W. temperature sensor or Central Heating Temperature Sensor

(fig. 28)

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Identify the sensor from figure 28

• Disconnect electrical connection to the sensor

• Drain the affected service either D.H.W. or C.H.

• Unscrew the sensor

• Replace in reverse order

7.08

Water Pressure Switch

(fig. 28)

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Identify the switch from figure 28

• Disconnect electrical conne note positions to the switch

• Drain the boiler

• Unscrew the sensor

• Replace in reverse order

7.09

Safety Valve

(fig. 28)

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Identify valve from fig. 28

• Drain the boiler

• Release the outlet union to the valve and

undo the valve

union connection

• Remove the valve outlet fitting

• Replace in reverse order

Fig. 26

Summary of Contents for FALCON II

Page 43: ......