www.felixprinters.com

Page

33

of

65

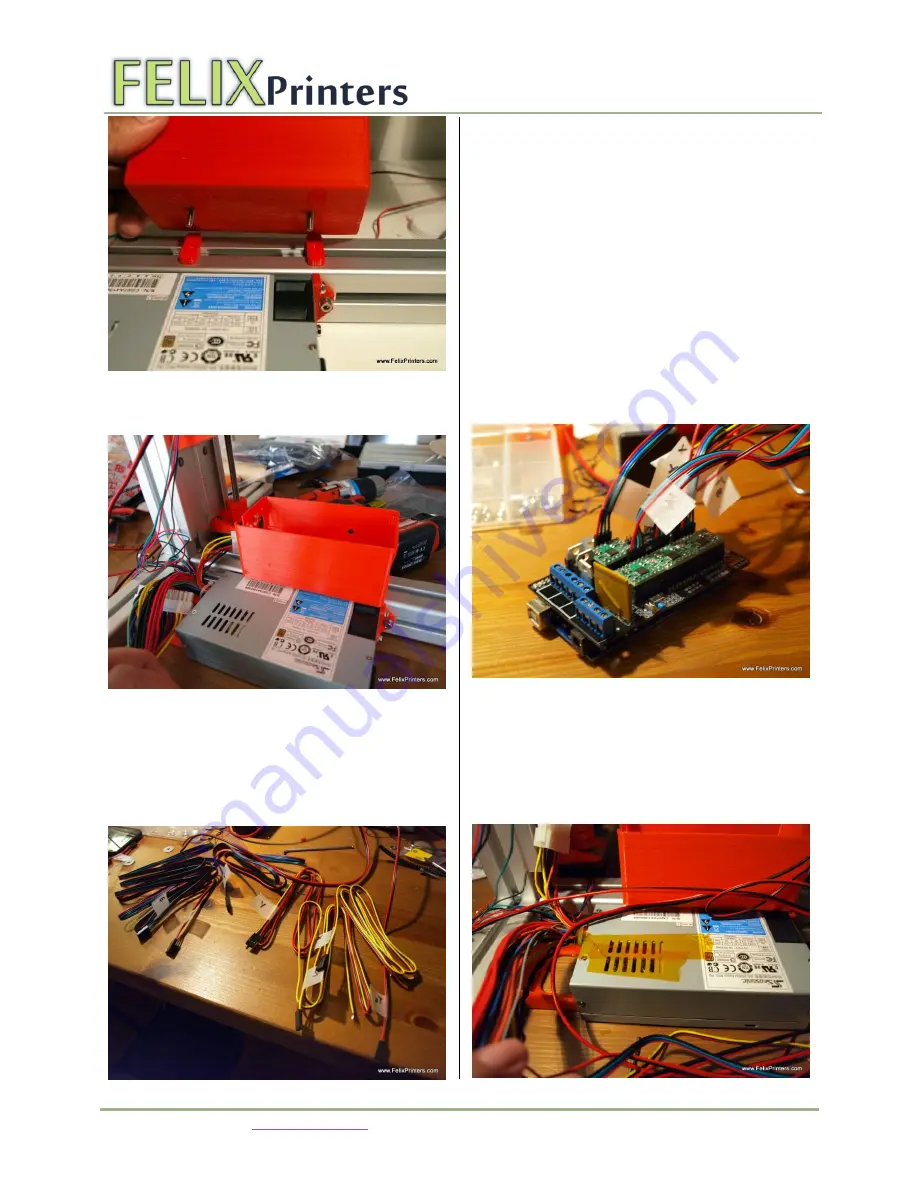

Mount the case also with t-slot nuts and the ramps_support parts.

Use the m4x12 buttonhead screws.

IMPORTANT

: Align the front face of the ramps case with the front

face of the powersupply. When the electronics case is placed too

close to the vertical beam, the z-axis carrier will touch the ramps

case, before it is at the end of its stroke.

Put labels on all cables

It is very usefull to label all the cables, especially when you want

remove a cable in the future for whatever reason. A easy way of

labeling is to fold a piece of tape around near the connectors, and

write something on it with a permanent marker.

The three wired cables are for the opto sensors, the 4 wired cables

are for the motors and the 2 wired cables are for the heated bed

and hot-end temperature sensors (these are already mounted onto

the parts.).

10.2

Connect all possible wires to the electronics

board.

We want to work our way from the electronics board to the components.

Connect all the pre-crimped cables, onto the board, the labels should

correspond to the position on the board. Try to group the 3wire cable

together.

Tip: make good use of the cable ties supplied with the kit. They are great

to form nice cable loops. Afterwards, it is easy to remove the unnecessary

ones.