33

Bandsaw

FB 540/640/740/840/940

Maintenance

8.2.3 Replacing the rubber wearing surface of the upper wheel

It is strongly recommended to let a specialist or the manu-

facturer itself to carry out this work, as the rubber wear-

ing surface is not just glued on but is also profile sanded.

The wearing surface may not, under any circumstances,

8.2.4 Cleaning and lubrication

Clean the inside of the machine regularly with a vacuum

to remove saw dust deposits and remove resin deposits

from the wheel surfaces. The wheel bearings are sealed

and do not need to be lubricated again.

It is not necessary to grease any parts on the machine,

as the circulating saw dust would otherwise immedi-

ately stick to every greased or oiled surface, and would

hamper the sliding properties of, for example, the blade

guidance or the belt tension unit. Regularly control the

cleanliness of the wheel wearing surfaces, especially af-

ter resinous materials or chipboards have been cut. Only

clean the wearing surfaces once the machine is idle and

ensure that the wearing surfaces are not damaged dur-

ing the process.

be sanded directly on the machine, e.g. with a file, sand-

ing paper or similar tools

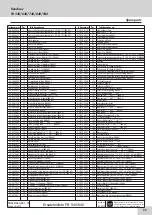

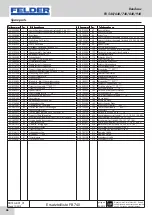

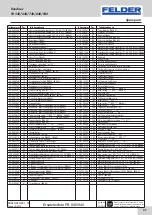

Summary of Contents for FB 540

Page 5: ...5 Bandsaw FB 540 640 740 840 940 Table of Contents...

Page 40: ...40 Bandsaw FB 540 640 740 840 940 11 Spare parts Spare parts...

Page 41: ...41 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 42: ...42 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 43: ...43 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 44: ...44 Bandsaw FB 540 640 740 840 940 Spare parts...