21

7. BASIC BREAKER MAINTENANCE

7.1 MAINTENANCE REOUIREMENTS

TYPE H-3 AND HL-3 BREAKERS SHOULD UNDERGO SYSTEMATIC

INSPECTION, LUBRICATION AND SERVICING AT THE FOLLOWING

INTERVALS:

EVERY 1750 OPERATIONS FOR 600 AND 800 AMP BREAKERS.

EVERY 500 OPERATIONS FOR 1600 AND 2000 AMP BREAKERS.

EVERY 250 OPERATIONS FOR 3000 AMP AND ABOVE.

IN MANY INSTALLATIONS, IT MAY TAKE YEARS FOR A BREAKER

TO REACH THESE NUMBERS OF OPERATIONS. FOR THESE CASES

ANNUAL MAINTENANCE SHOULD BF PROVIDED. FOR BREAKERS

OPERATING IN VERY CLEAN ENVIRONMENTS, THIS INSPECTION

PERIOD COULD BE EXTENDED TO 2 YEARS. CONVERSELY,

BREAKERS THAT OPERATE IN VERY DUSTY, CORROSIVE OR OTHERWISE

ADVERSE ENVIRONMENTS REQUIRE INSPECTIONS AND SERVICE EVEN

MORE FREQUENTLY.

SECTION 7.2 CONTAINS A LIST OF THE MAINTENANCE TOOLS AND

SUPPLIES THAT WILL BE REQUIRED AND SUMMARY/CHECKLIST OF

THE BASIC MAINTENANCE PROCEDURES.

SECTION 7.3 DESCRIBES THE FULL PROCEDURE.

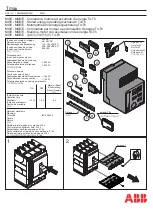

7.2 TOOLS AND CHECKLIST,

THE FOLLOWING TOOLS AND SUPPLIES WILL BE VALUABLE FOR

BASIC BREAKER MAINTENANCE:

•

AN ASSORTMENT OF SLOT AND ROBERTSON HEAD SCREWDRIVERS.

•

A WRENCH AND SOCKET SET (IN PARTICUTAR, A 7/16 INCH "DEEP"

SOCKET IS USEFUL FOR REMOVING ARC CHUTES).

•

A FEELER GAUGE.

•

AN EMERGENCY CHARGING HANDLE FOR ELECTRICALLY OPERATED

UNITS.

•

A DRAWOUT CRANK (if NONE IS AVAILABLE, A 1/2 INCH DRIVE

RATCHET AND EXTENSION CAN BE USED).

•

A SLOW-CLOSE HANDLE, DEFLECTION GAUGE, DEFLECTION AND

DIFFERENTIAL SHIMS AND A SMALL PIECE OF BEAR-TEX OR

SIMILAR ABRASIVE FIBRE MATERIAL, ALL OF WHICH ARE

AVAILABLE FROM SCHNEIDER ELECTRIC (SEE SECTION 9.1 ).

•

IF THE MECHANISM IS VERY DIRTY A CLEANING SOLVENT MAY BE

REQUIRED.

•

FOR LUBRICATION, USE CAT. NO. PJC-8311 HIGH TEMPERATURE

LUBRICATING GREASE, PART NO. 70.15.001A.002.

MAINTENANCE SUMMARY CHECK LIST

1. REMOVE OR ISOLATE BREAKER

2.

REMOVE AND INSPECT ARC CHUTES, FLASH SHIELDS, FACEPLATE

3. CLEAN BREAKER

4. CLEAN MAIN AND SECONDARY DRAWOUT CONTACTS

5. INSPECT MOULDINGS AND HARDWARE

6. INSPECT ARCING CONTACTS

7. INSPECT BRAIDS

8. INSPECT MAIN CONTACTS

9. CLEAN CLOSING MECHANISM AND DRAWOUT MECHANISMS

10. CHECK TRIP LATCH

11. CHECK CLOSE LATCH

12. LUBRICATE

13. CHECK CLOSING MECHANISM TOGGLE

14. CHECK DIFFERENTIAL

15. CHECK DEFLECTION

16. CHECK AND OPERATE CONTROL AND TRIP DEVICES

17. REASSEMBLE

18. CLEAN CRADLE MOULDINGS, CONTACTS

19. INSPECT CRADLE

20. LUBRICATE CRADLE

21. PLACE BREAKER BACK IN SERVICE

7.3 BASIC MAINTENANCE PROCEDURE

1. REMOVE OR ISOLATE BREAKER.

FOR FIXED MOUNTED BREAKERS, BEGIN BY ENSURING THAT

THE BREAKER IS ISOLATED FROM BOTH MAIN AND CONTROL POWER

SOURCES. TRIP THE BREAKER AND OPEN THE COMPARTMENT DOOR.

FOR DRAWOUT MOUNTED BREAKERS, WITHDRAW THE BREAKER

FROM THE CUBICLE (REFER TO SECTION 4.10 REGARDING DRY RUNS).

MOVE THE BREAKER TO A BENCH FOR BETTER ACCESS AND

VISIBILITY IF POSSIBLE.

BEFORE BEGINNING WORK ON THE BREAKER, CHECK THE

BOTTOM OF THE CRADLE FOR ANY HARDWARE, RETAINERS OR

BROKEN PARTS. THE SOURCE OF THESE ITEMS SHOULD BE LOCATED

AND MISSING HARDWARE OR BROKEN PARTS REPLACED.

2.

REMOVE AND INSPECT ARC CHUTES, FLASH SHIELDS, FACEPLATE

BEGIN DISASSEMBLY AND INSPECTION. AS EACH PART IS

REMOVED, WIPE IT CLEAN WITH A DRY RAG AND INSPECT FOR

CRACKS OR DISTORTION.