6

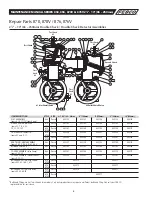

Service Procedures for Series 850, 856, 870V & 876V 2

1

⁄

2

"-10"(65-250mm)

MAINTENANCE MANUAL SERIES 850, 856, 870V & 876V 2

1

⁄

2

"- 10" (65 – 250mm)

Check Valve Disassembly and Reassembly

1 . Spring Module Removal

a . Slowly close outlet shutoff valve and inlet shutoff valve .

Bleed residual pressure by opening #4, #3, and #2 test cocks

(See Page 11 for test cock location) .

b . Remove cover bolts, removing the two bolts last that are located

next to the retainer pin . Remove cover .

NOTE:

Spring module is positioned in the body by the cover .

Spring is captured in the module .

c . Refer to Page 11-12 . Remove pivot bearing (Item 13) from the

upper spring retainer of the spring module . Inspect pivot bearing

(Item 13) and bearing socket (Item 15) . Small hole in bearing socket

indicates replacement is required . Remove retaining clip (Item 5 .1)

from groove on one end of the load pin (Item 7) . Hold spring module

with one hand while sliding out load pin (Item 7) from arm (Item

4) . Lift out spring module and inspect for wear or damage . Replace

spring module if necessary .

2 . Check Disk Removal

a . Remove jam nut (Item 16) and washer (Item 17) from check disc

stem threads . Lift the arm and remove the check disc (Item 6) .

Inspect sealing surface for debris or damage . Replace check

disc if necessary .

NOTE:

When jam nut (Item 16) is tight, check disc

is designed to “wobble .”

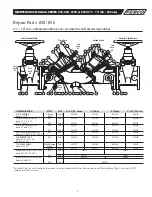

3 . Seat Ring Assembly Removal

NOTE:

Remove the seat ring assembly only if the seat ring (Item 3)

or arm (Item 4) appear to be worn or damaged .

a . Remove locknuts (Item 3 .4) . (See above drawing) .

NOTE:

When reassembling, tighten locknuts to 40-50 in ./lbs . If leaking

occurs around bolt, further tighten until leaking stops . Do not

over tighten .

b . Remove seat ring assembly .

c . Remove retaining clip (Item 5) from one end of the swing pin

(Item 4 .2) . Hold arm (Item 4) while sliding out swing pin (Item 4 .2) .

Inspect bushings (Item 4 .1) and pin (Item 4 .2) for wear or damage .

Replace if necessary . Inspect gasket (Item 3 .1) for debris and/or

damage . Replace if necessary .

NOTE:

Reverse the previous procedure to reassemble the compo-

nents . Seat ring will only fit into body one way . Check align-

ment of seat ring if studs do not align with body holes . Gasket

is also non-symmetric . Both seat ring and gasket have a notch

that indicates non-symmetric hole . Clean all parts thoroughly

with clean water before reassembly . Reassemble and bleed

test cocks #4, and #3 . Repressurize the assembly and test to

ensure proper operation .