4

MAINTENANCE MANUAL SERIES 850, 856, 870V & 876V 2

1

⁄

2

"- 10" (65 – 250mm)

Freeze Protection

The Double Check Backflow Prevention Assembly may be subject to

damage if the internal water is allowed to freeze . The unit must be pro-

tected from freezing using a heated enclosure, insulation using heat tape,

or other suitable means . The unit must always be accessible for testing

and maintenance . If the system will be shut down during freezing weath-

er, use the following procedures to drain internal passages .

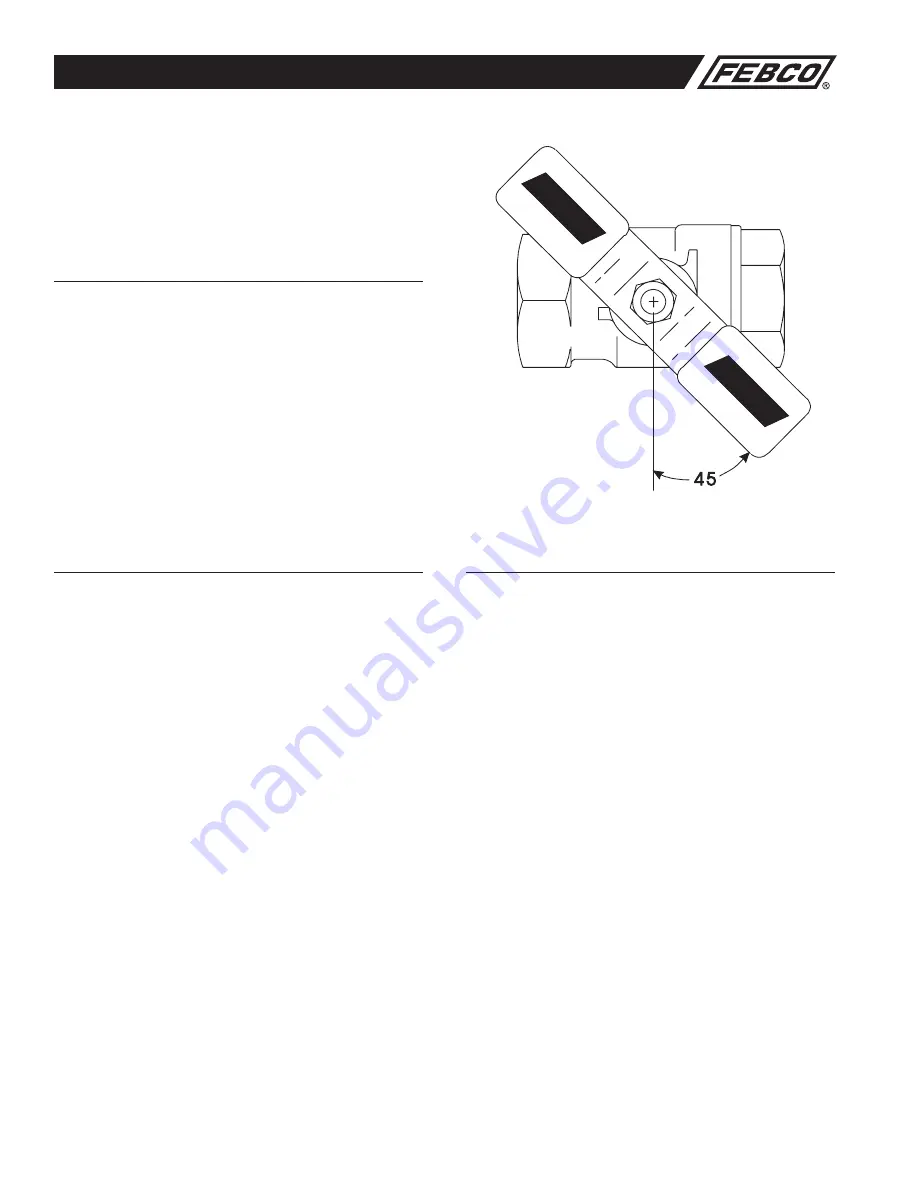

Ball Valve Shutoff Draining Procedure

If the assembly has been installed with ball valve shutoff valves, they

must also be properly drained to prevent freeze damage . After draining

procedure has been completed on the backflow prevention assembly,

position all ball valve shutoffs and test cocks in a half open/half closed

(45 degree) position .

Open the ball valve approximately 45 degrees while draining the pipeline

and assembly to allow water between the ball valve and valve body

to drain . Leave the ball valve in this position for the winter to prevent

freeze damage .

The ball valve must be fully closed before the system is repressurized .

OPEN AND CLOSE BALL VALVES SLOWLY TO PREVENT DAMAGE

TO THE SYSTEM CAUSED BY WATER HAMMER.

Main Valve Draining Procedure

1

⁄

2

"-2" (15-50mm)

1 . Close the main shutoff valve .

2 . Open the inlet drain .

3 . Open the inlet and outlet ball valves 45 degree (half open, half closed) .

4 . Open all testcocks .

5 . Open the outlet drain .

6 . Remove the cover and inlet check module until all water inside valve

drains back out through inlet drain .

7 . If you “blowout” the piping downstream of the backflow assembly

using compressed air:

Connect the air supply to the outlet drain and close the outlet ball valve .

After clearing the system with air, partially open the outlet ball valve .

Leave all drain valves, testcocks, and ball valves in half open/half closed

position for the winter . (See above for more detailed instructions) .

Main Valve Draining Procedure

2

1

⁄

2

" - 10" (65-250mm)

Slowly close supply valve within freeze protected area, open all test

valves on the backflow preventer . For sizes 2

1

⁄

2

" - 10" (65-250mm), water

within the zone between the two checks may be drained by loosening

the bolts (Item 24) on the bottom cover plate (Item 19) . (See Page 8) .

All water will be drained from the inlet side and the zone between the

two checks of the Series 870V . All water on the inlet side will be drained

down to the No . 1 test cock on the Series 850 . The remaining water on

the inlet side may be drained to the lowest point on the Series 850 2

1

⁄

2

"

- 10"

(65-250mm) by removing the small (Item 36) bottom plate . (See Page 8) .

If you desire to add a drain plug, there is sufficient material for drilling and

tapping

1

⁄

4

" IPS thread in the cover (Item 19); however, adding a drain plug

is not necessary . Loosen the mounting nuts and bolt to allow drainage

from beneath the plate .

The system design must provide a means for draining upstream of the #1

shutoff valve and downstream of the #2 shutoff valve .

Position the assembly shutoff valves and test cocks in the half open/half

closed position to allow complete draining of the assembly shutoff valve

bodies and test cocks . (See above) .