2

Feature and Operating Procedures

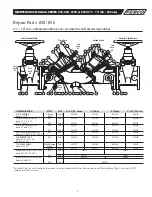

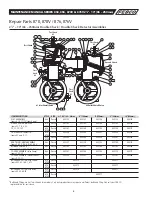

MAINTENANCE MANUAL SERIES 850, 856, 870V & 876V 2

1

⁄

2

"- 10" (65 – 250mm)

Double Check Valve Assembly Operation

The FEBCO Double Check Valve Assemblies consist of two indepen-

dently operating, spring loaded check valves . The pressure drop across

the first check valve is approximately 1 .0 psig with no flow . The pressure

drop across the second check valve is also 1 .0 psig with no flow .

A complete assembly includes two shutoff valves and four test cocks .

NOTE:

The 870V and 876V, when installed in the vertical orientation,

must include vertical support under the second check body section .

Double Check Detector Assemblies

Bypass Operation

All low flow demands up to a minimum of three GPM are to pass only

through the bypass assembly .

All flows above three GPM will pass through both the bypass and main-

line valve without accurate meter registration .

How to Order Parts/Repair Kits

1) Locate item number and kit number in this maintenance manual .

2) Verify the size of the valve the parts are to be used on .

3) Provide full model number located on I .D . plate .

4) Give kit number .

5) A serial number (located on the I .D . plate) will assist in ordering

the proper kits .

6) Contact your local FEBCO Parts Distributor .