ST100 Series Configuration Software

Fluid Components International LLC

3

Password Protection

To protect against unwanted/unauthorized change, two levels of password protection are provided:

User

and

Factory

. The User level pass-

word is associated with common user-accessed parameters that can only be changed after entering the User password. The Factory level

password is associated with more sensitive programming that can only be modified by the factory or its representatives. The dialog box for

password entry is shown below. When prompted, type the password and then click

OK

. The User password is: 2772. The password is also

shown in this manual with the tab summary tables.

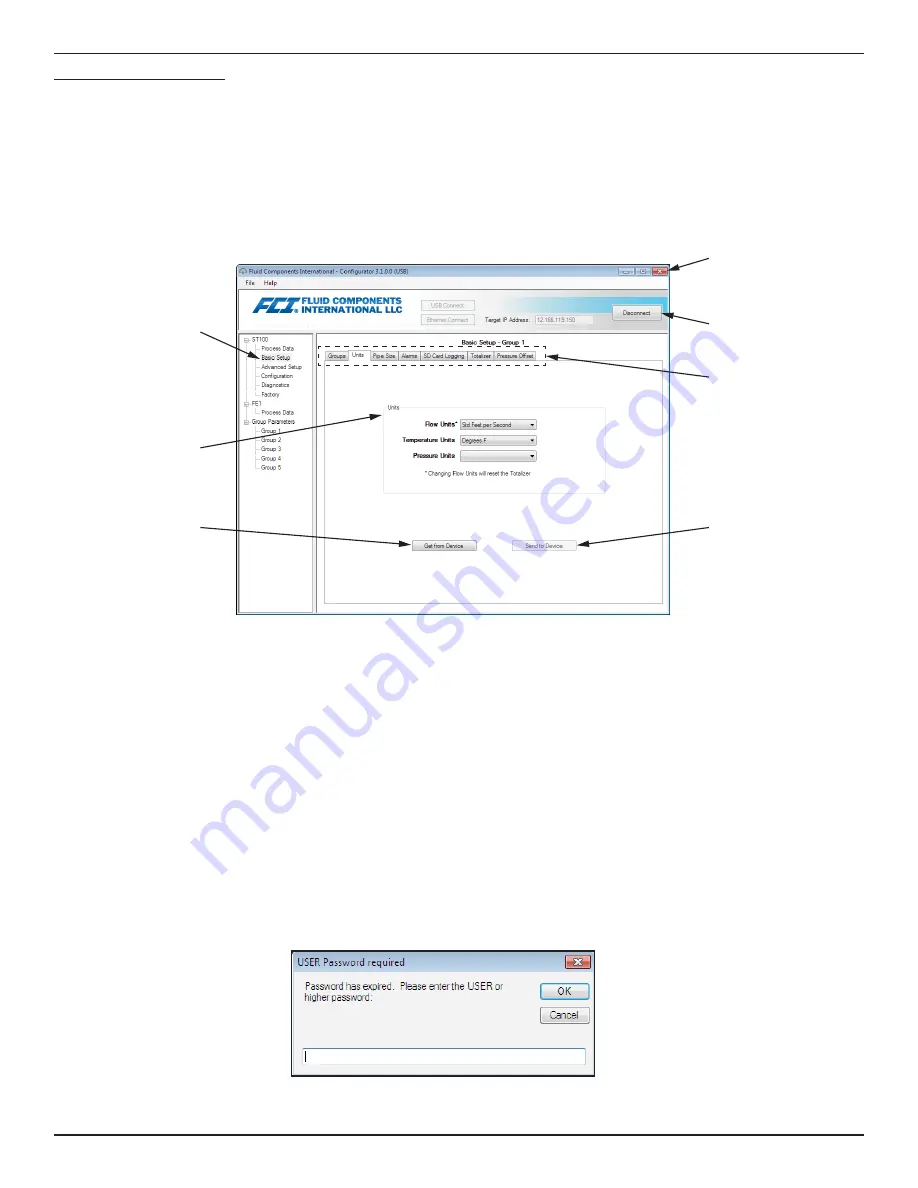

Configuration Software Basics

The ST100 is set up using a configuration menu arranged in a hierarchical tree structure on the left side of the window. Select a menu item to see the

related tabs on the right side of the window. Within the tab area parameter data is typically organized into one or more data fields, which are set off

with a thin divider line or a thin box outline.

Many screens show

Get from Device

and/or

Send to Device

buttons at the bottom portion of the window. These buttons are shown if the window

tab includes parameter data that can be retrieved from the instrument for display (

Get from Device

) and/or transmitted to the instrument for

programming (

Send to Device

). The

Send to Device

button is normally grayed out (inactive) initially until a change is made in a data field. Once a

parameter change is detected, the

Send to Device

button becomes active as shown by its solid appearance.

Figure 4 – Basic Application Screen Elements

Note

:

Once the PC’s configuration software is communicating with the instrument, some HMI display items/menus are inactive due

to control being handed over to the configuration application. For example, front panel selection of groups in the Service menu

(HMI Setup mode) is inactive. Inactive HMI display menu items are shown with an asterisk (for example,

Select Group*

).

Click

Disconnect

to break the connection between the PC and ST100. Click the application window

Close

button or type ALT+F4 (with the applica-

tion window having the focus) to quit the application altogether.

C01401-1-1

Tabs

Menu

(Basic Setup

Branch)

Data Field

(Units)

Disconnect

Button

Application

Close Button

Get from Device

Button

Send to Device

Button

(Grayed)