FS10 Series

APPENDIX A – APPROVALS

Fluid Components International LLC

57

SIL Information

Flow/Liquid Level/Temperature Instrumentation

Visit FCI on the Worldwide Web:

www.fluidcomponents.com

1755 La Costa Meadows Drive, San Marcos, California 92078 USA 760-744-6950

800-854-1993

760-736-6250

European Office: Persephonestraat 3-01 5047 TTTilburg – The Netherlands – Phone 31-13-5159989

Fax 31-13-5799036

Doc no. 23EN000026-

SIL DECLARATION OF CONFORMITY Model FS10 SERIES

We,

Fluid Components International LLC,

located at 1755 La Costa Meadows Drive, San Marcos, California 92078-

5115 USA, declare as manufacturer, that the

FS10 Series

of products is suitable for use in a safety instrumented

system for SIL 2, flow and temperature measurement.

The FS10 Series has been classified as Type B subsystem according to IEC 61508-1 Chapter 7.4.4.1.3 with a

Hardware tolerance (HFT) of 0.

The Failure Modes, Effects and Diagnostic Analysis (FMEDA) report carried out by

exida

, resulted in following

failure ratings:

SIL (Safety Integrity Level)

:

2

HFT (Hardware Fault Tolerance)

:

0

Subsystem

type

: B

Failure rates according to IEC 61508-1

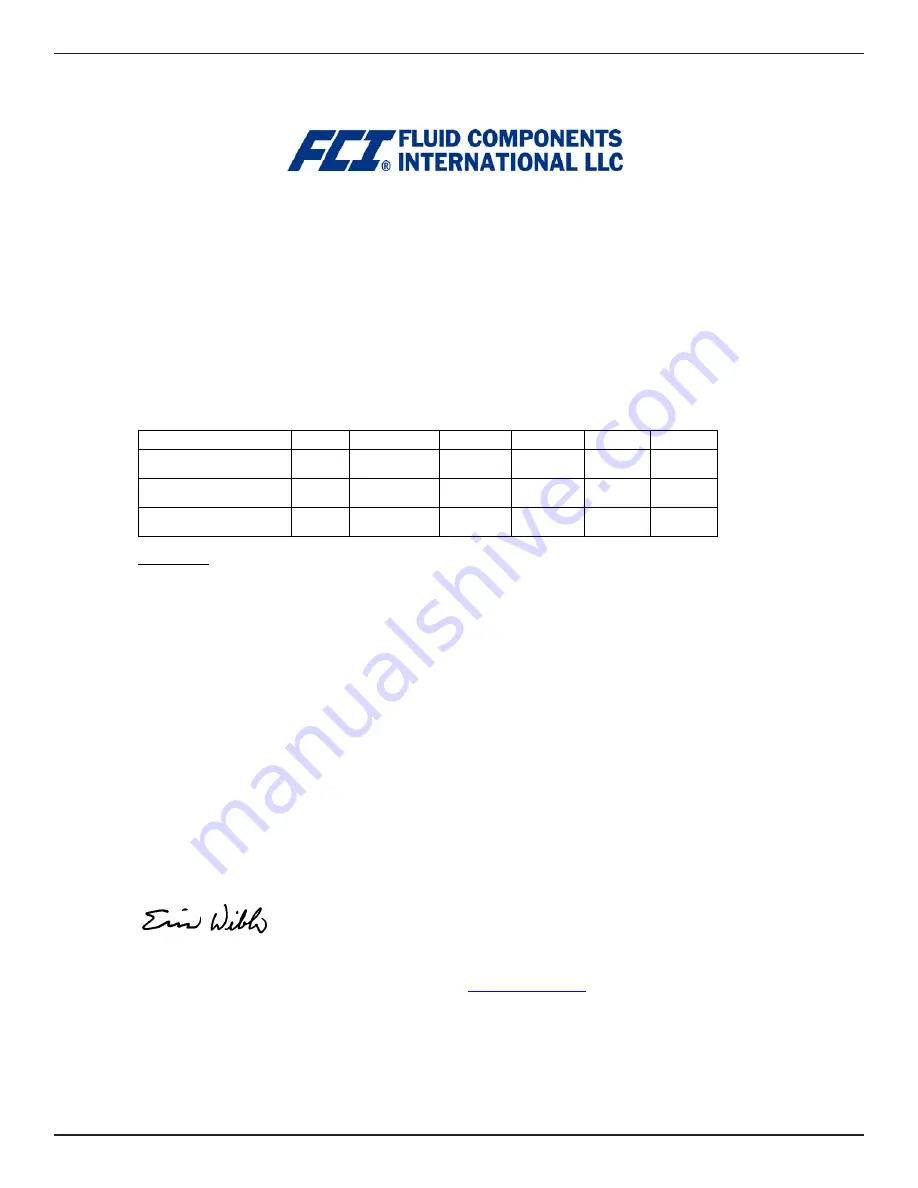

Device Configuration

SFF

PFD

AVG

λ

SD

λ

SU

λ

DD

λ

DU

Relay output,

alarm on low or high flow

90% 1.54E-03 900 240 860 232

Transistor output,

alarm on low or high flow

90% 1.44E-03 900 220 860 213

Current output,

alarm on low or high flow

90% 1.54E-03

-

217 1784 215

Terminology:

SFF = Safe Failure fraction

PFD = Probability of failure on demand

λ

DU

= failure rate dangerous undetected faults

λ

DD

= failure rate dangerous detected faults

λ

SU

= failure rate safe undetected faults

λ

SD

= failure rate safe detected faults

FIT = Failure Rate in 10

-9

/hour

Above analysis is based on assuming:

The PC interface is only used for setup, calibration, and diagnostics purposes, not for safety critical operation.

The programming push-buttons are monitored for short circuit failures. (Firmware v4.02 or greater)

The application program in the logic solver is constructed in such a way that Fail High and Fail Low failures are

detected regardless of the effect, safe or dangerous, on the safety function.

Materials are compatible with process conditions.

The device is installed per manufacturer’s instructions.

External power supply failure rates are not included.

Worst-case internal fault detection time is 3 seconds. This is based on the default 0 second Time Delay and

includes the default 2 second Filter Setting

With the relay output option ,either the NC or the NO contacts are used.

With the relay output option the customer must provide components to limit the contact current to 60% of the

rating and provide transient voltage protection (600mA resistive, refer to manual for inductive loads).

Proof test interval of 1 year.

Issued at San Marcos, California USA

April 2013

______________________________________

Eric Wible, Engineering Manager

Eric Wible

2013.04.09 08:36:18 -07'00'