5.

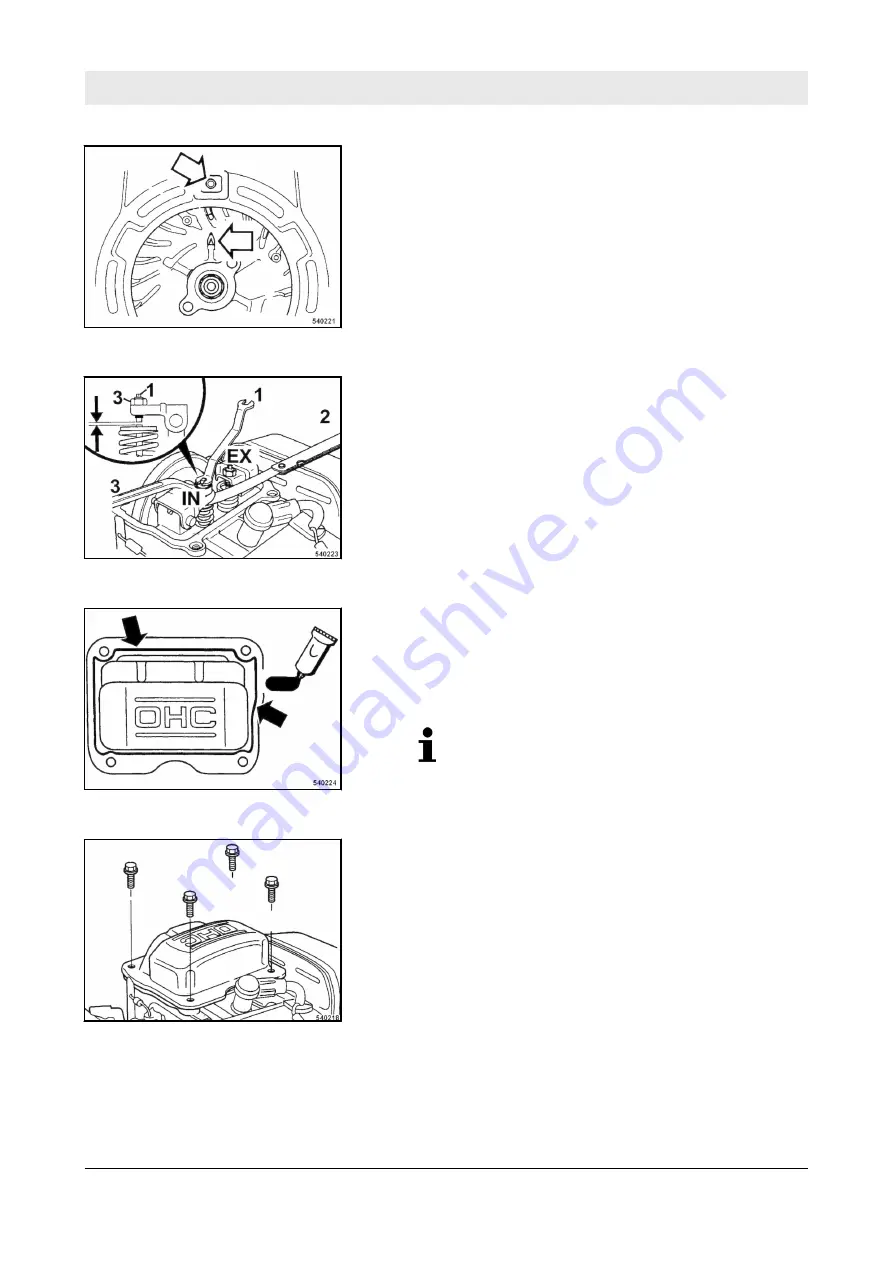

Align the alignment mark on the flywheel rib with the top bore

of the fan cover.

ð

The piston is in top dead centre position of the compres-

sion stroke.

6.

However, if the exhaust valve is open when aligning the

marks, the flywheel must be turned further by 360°.

7.

Check the valve clearance with a feeler gauge (2).

8.

To adjust the valve, hold the valve adjustment screw (1) and

loosen the locking nut (3).

9.

Turn the valve adjustment screw in or out, as required.

10.

Retighten the locking nut, tightening torque: 8 Nm (6 ft·lbf).

11.

Clean the sealing faces on cylinder head cover and cylinder

block.

12.

Apply a bead of liquid sealant, approx. 1.5 to 2.0 mm

(0.06 to 0.08 in) in diameter, to the inner side of the cylinder

head cover.

Liquid sealant: Three Bond 1207B or similar.

13.

Attach the cylinder head cover to the cylinder block within the

next 10 minutes.

14.

Tighten the fastening screws.

Fig. 68

Fig. 69

Fig. 70

Fig. 71

Maintenance – Annually

DR7X

77

Summary of Contents for Dynapac DR7X

Page 2: ...2 ...

Page 6: ...Table of contents DR7X 6 ...

Page 7: ...1 Introduction Introduction DR7X 7 ...

Page 11: ...2 Technical data Technical data DR7X 11 ...

Page 15: ...3 Concerning your safety Concerning your safety DR7X 15 ...

Page 37: ...4 Indicators and control elements Indicators and control elements DR7X 37 ...

Page 39: ...5 Checks prior to start up Checks prior to start up DR7X 39 ...

Page 45: ...6 Operation Operation DR7X 45 ...

Page 56: ...Operation Operating hour meter engine rpm meter DR7X 56 ...

Page 57: ...7 Loading transporting the machine Loading transporting the machine DR7X 57 ...

Page 61: ...8 Maintenance Maintenance DR7X 61 ...

Page 96: ...Maintenance As required DR7X 96 ...

Page 97: ...9 Setting up refitting Setting up refitting DR7X 97 ...

Page 99: ...10 Troubleshooting Troubleshooting DR7X 99 ...

Page 106: ...Troubleshooting What to do if the engine has flooded DR7X 106 ...

Page 107: ...11 Disposal Disposal DR7X 107 ...

Page 109: ......

Page 110: ......