52

1 - Agitation Throttling Valve

If the sprayer has a self cleaning filter, the agitation throttling

valve will be the first valve located at the bottom of the valve

control center tower. See preceding page for location.

There are three agitation jets inside the product tank. Two

are located in the sump near the front of the tank and one is

located at the rear of the tank.

NOTE: If the sprayer is equipped with a self cleaning filter

the jet at the rear of the tank will be controlled by the self

cleaning filter. See the self cleaning filter section for details.

It is recommended that you have the agitation throttling

valve completely OPEN unless foaming occurs.

9.13 Standard Primary Filter

Your sprayer is equipped with a primary filtration system.

This filter could be in the form of a “Y” strainer (standard)

or a self cleaning filter (optional). The filter is located on the

right side of the sprayer under the sprayer platform. The

filter is installed on the pressure side of the pump and has

a 50 mesh screen. Other size mesh screens are available

through Fast Manufacturing, Inc.

9.14 In Line Filter Kit

The in line filters are located on the mid section of the boom

and are attached to the ON/OFF valves. There will be one

filter per ON/OFF valve and are equipped with 50 mesh

screens. Optional size screens are available through your

Fast Manufacturing parts dealer.

^

WARNING

Wear protective clothing (such as goggles,

rubber or chemical resistant gloves and a

respirator) while handling or working with

chemicals. Keep protective clothing clean and

in good condition or discard.

To clean screens:

1. Use caution when removing filter canisters or boom

lines. There could be residual pressure in the filter or

boom lines.

2. Place a container under the filter canister.

3. SLOWLY loosen and remove the drain plug from the

bottom of the canister and let filter drain completely.

4.

Unscrew the filter canister, remove the screen and rinse

in clean water.

5. Wipe the inside of the canister with a clean rag.

6.

Lightly oil the O-rings on the filter canister and the drain

plug.

7. Reassemble the filter screen into the canister and the

canister to the filter head. DO NOT over tighten.

8. Reinstall the drain plug into the canister. DO NOT over

tighten.

9. Dispose of the waste material properly.

9.15 Self Cleaning Filter (Optional)

Refer to the “Maintenance” section of this manual for filter

maintenance interval and procedures.

A self cleaning filter is an optional accessory. This filter has

a throttling valve located in the front left hand side of the

sprayer. A quick coupler system and hose is mounted to

the bottom of the filter cannister. The unmixed chemical that

does not go through the 50 mesh screen is returned to the

product tank through the rear agitation jets, reagitated and

sent back through the system.

•

The throttling valve should remain completely open for

the self cleaning filter to operate properly.

When the cannister is removed from the filter head, the

throttling valve MUST be closed.

To clean the filter screen:

^

DANGER

Agricultural chemicals are TOXIC, chemicals

not safely used, handled, stored and disposed

of can cause serious injury or death to

individuals or harm the environment.

Wear protective clothing and equipment.

Read, understand and follow the chemical

manufacturer’s label.

Contact your chemical supplier, county

extension agent or other qualified person if

you have questions on chemical usage.

1. Turn the product pump OFF.

Summary of Contents for BW750

Page 18: ...18...

Page 19: ...19 Decal A Decal B Decal C Decal D...

Page 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Page 21: ...21 Decal K Decal L...

Page 36: ...36 9 6 Spray Tip Wear...

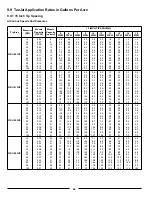

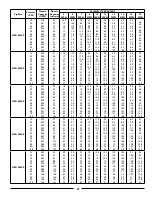

Page 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Page 81: ...81 12 3 Raven Console Calibration Information...

Page 83: ...83 Notes...