59

1 - Chemical Inductor Tank Cover

2 - Chemical Inductor Tank

3 - Chemical Inductor Venturi

4 - Valve At Bottom Of Inductor Tank

5 - Agitation Control Valve

6 - Chemical Fill Control Valve

7 - Hand Rinse Gun

NOTE: Some chemicals tend to foam when agitated. If

foaming occurs, throttle back the agitation valve until the

foaming stops. If you change the agitation valve setting, you

may have to adjust the pressure on the tractor control box.

This adjustment would not be necessary with a RAVEN rate

controller.

NOTE: There are anti foaming agents available:

• Part No. 07.06881 Shakedown, Liquid - 1 Pint

• Part No. 07.06880 Shakedown, Dry - 1/2 lb. jar

• Part No. 07.06879 Shakedown, Water Soluble Packets

- 30 per case

10.

If you are mixing more than one chemical into the

product tank, you should check with your chemical

supplier to make sure you add the chemicals in the

correct sequence to insure proper mixing.

11.

Be certain to clean and dispose of empty chemical

containers properly. Follow the instructions on the

container.

NOTE: DO NOT use the chemical inductor system for

powder type chemicals. Flowable granular chemicals are

acceptable.

IMPORTANT: The “Tee” fitting at the bottom of the chemical

inductor is a special fitting with a venturi nozzle on the

inside. NEVER operate the chemical inductor without the

venturi nozzle installed.

Control Box

1 - Pressure Gauge

2 - Pressure Adjust Switch

9.21 Hand Rinse Gun for Chemical

Inductor (Optional)

The chemical inductor is supplied with a hand gun with

approximately 5 feet of hose to rinse the chemical inductor

tank.

There are two ways the hand gun can be supplied with

water:

• Standard system via the product pump

• Optional electric system via a 12 volt electric pump

9.21.1 Standard System

•

The standard system supplies water from the sprayer

tank via the product pump and has an ON/OFF valve

located at the top of the control center. The control

center is located at the front of the sprayer.

•

The water supplied will be contaminated with diluted

mixed chemical.

To Operate:

1. Start the product pump. Be certain to have water in the

product tank and the emergency shut off valve under

the product tank is open.

2. Open the ON/OFF valve located at the top of the control

center.

3. Remove the hand gun from the storage bracket and

rinse the chemical inductor tank.

4.

When finished close the ON/OFF valve, point the hand

gun into the chemical inductor tank and squeeze the

trigger to drain the pressure from the hand gun and

hose.

Summary of Contents for BW750

Page 18: ...18...

Page 19: ...19 Decal A Decal B Decal C Decal D...

Page 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Page 21: ...21 Decal K Decal L...

Page 36: ...36 9 6 Spray Tip Wear...

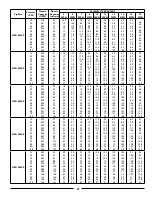

Page 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Page 81: ...81 12 3 Raven Console Calibration Information...

Page 83: ...83 Notes...