INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 29 of 168

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

12.6.2 Demounting

THROUGHOUT TYRE MOUNTING/

DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (160 - 180

BAR).

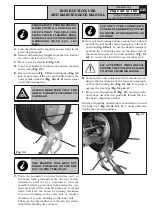

Tubeless tyres can be removed in two ways:

A.

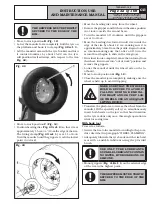

If the wheel does not present particular problems,

continuing beading operation will completely dislod-

ge the beads from the rim. The inner bead, pushed

by the disc, presses against the outer one till it has

been completely removed (see

Figure 32

).

Fig. 32

B.

If the wheel is especially hard, it is not possible to

carry out the procedure described in point

A

. A

different procedure will be necessary: use the hook

tool and follow this sequence of operations:

• Move to work position

C

(

Fig. 12

).

Only for GG40256.11SL - GG40256.11ST -

GG40256.15 - GG40256A.15 - GG40256D.15

- GG40256.15SL - GG60360.15 - GG60360A.15

- GG60360D.15 versions

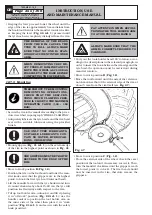

• Position the tool holder arm on the outer side of the

wheel and bring forward the hook tool, inserting it

between rim and bead until it is secured to the bead

itself (see

Fig. 33

).

Fig. 33

• Move the rim away from the tool by about 4-5 cm

to avoid possible unhooking of the bead from the

same tool.

• Move to work position

A

(

Fig. 12

).

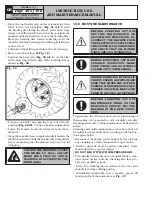

• Translate the tool outwards (

Fig. 34 ref. 2

) to al-

low easy insertion of lever (

Fig. 34 ref. 1

) between

the rim and the bead; insert lever (

Fig. 34 ref. 1

)

between rim and bead on the right-hand side of the

tool (

Fig. 34 ref. 2

).

Fig. 34

1

2

• Keeping the lever pressed, lower the wheel until the

edge of the rim is 5 mm distant from the hook tool.

• Turn the wheel clockwise keeping lever pressed

(

Fig. 34 ref. 1

) until the bead has gone completely

out.

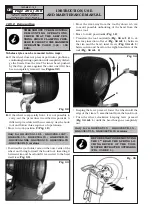

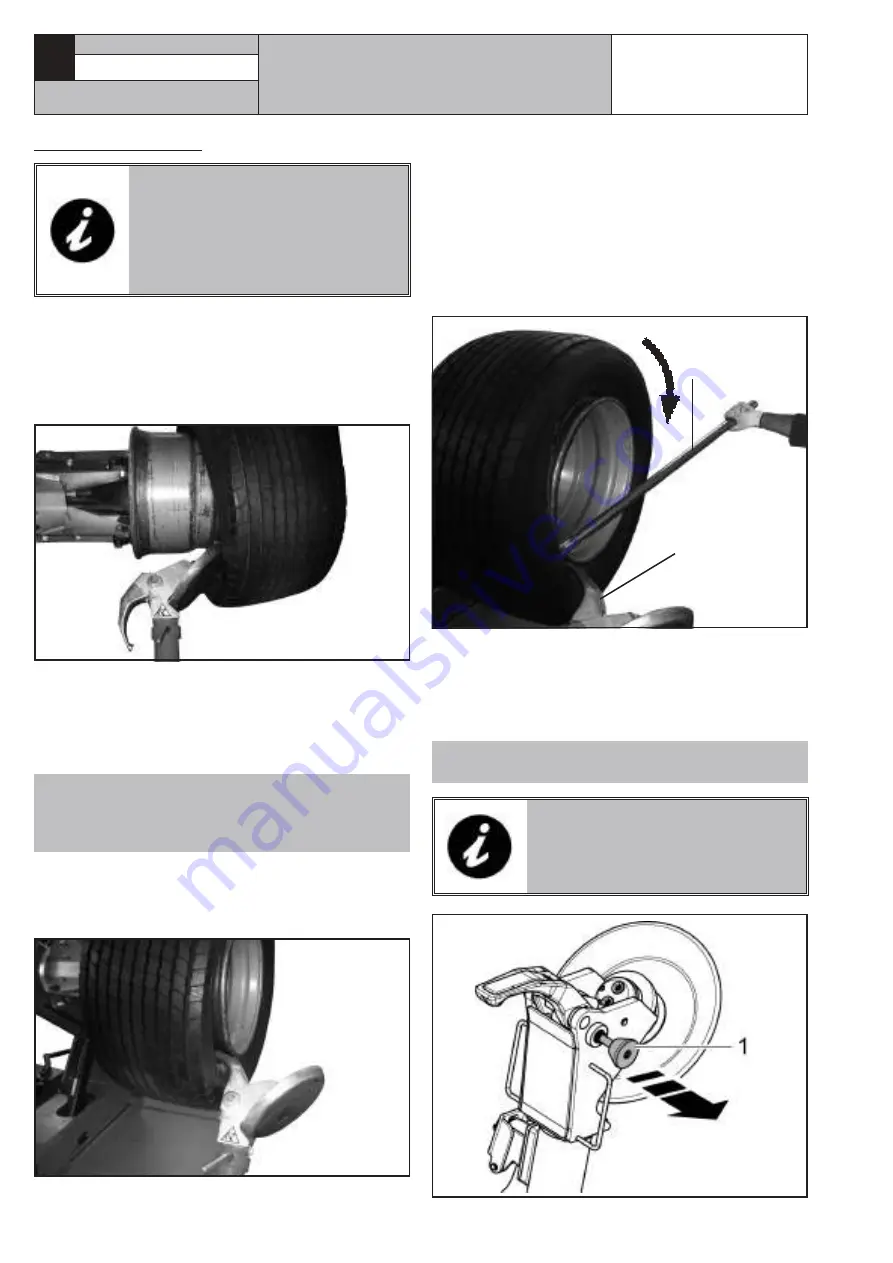

Only for GG40256T.15 - GG40256TD.15 -

GG60360T.15 - GG60360TD.15 versions

BEFORE STARTING DEMOUNTING

THE 1

ST

BEAD THE SPRING LO-

CKING DEVICE OF THE TOOL

MUST BE EXTRACTED OUTWARDS

(FIG. 35 REF. 1).

Fig. 35