INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 37 of 168

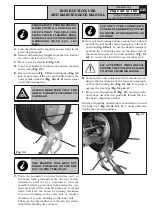

• Tilt up tool holder arm placing it in “out of work”

position (

Fig. 22 ref. 1

) after it has been unhooked.

• Lower the mandrel until the wheel rests on the fo-

otboard.

• Move to work position

B

(

Fig. 12

).

• Check the state of the tyre valve and centre it, if neces-

sary, in the rim hole by slightly turning the mandrel;

fix the valve with the supplied ring nut after having

removed the protective extension.

• Close the mandrel jaws completely, making sure the

wheel is held up to avoid dropping.

MAKE SURE THAT THE WHEEL’S

HOLD IS SECURE TO AVOID IT

FALLING DURING REMOVAL.

FOR HEAVY AND/OR VERY LAR

-

GE WHEELS USE AN ADEQUATE

LIFTING DEVICE.

• Translate the platform to release the wheel from the

mandrel.

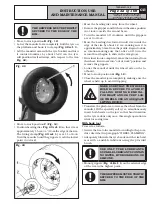

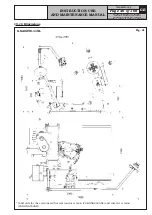

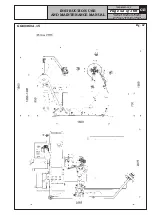

12.8 Wheels with bead wire

As an example

Fig. 51

and

52

illustrate sections and

compositions of types of wheels with bead wire cur-

rently being sold.

Fig. 51

Lock

ring

Lock

ring

Non split

side ring

Non split

side ring

Tapered

bead seat

ring

Three-piece flat base rim and

pertinent rings for tubed tyres

and SOLID tyres

Four-piece 5” tapered bead seat

rim and pertinent rings for tubed

and SOLID tyres

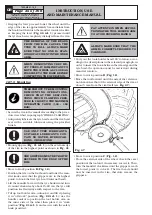

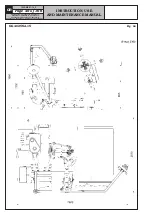

Fig. 52

Lock

ring

Lock

ring

Non split

ring

Non split

ring

Rubber seal-

ing ring

O-sealing

ring

12.8.1 Beading and demounting

NEVER STAND IN FRONT OF THE

WHEEL WHILE THE INFLATION

RING IS BEING EXTRACTED FROM

THE BEAD WIRE, SINCE IT MAY BE

EJECTED VIOLENTLY, CAUSING

SERIOUS INJURIES OR WOUNDS.

THROUGHOUT TYRE MOUNTING/

DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (160 - 180

BAR).

• Mount the wheel on the mandrel as described in

“WHEEL CLAMPING” and make sure it is deflated.

• Move to work position

D

(

Fig. 12

).

• Place the tool arm in “working position” (

Fig. 21

ref. 1

) in the tyre inner side, and make sure it is

locked by the provided safety stop (

Fig. 1, 2, 3, 4,

5, 6 or 7 ref. 8

).

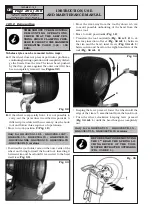

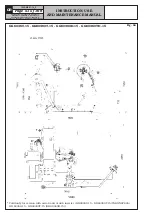

• Position the beading disc on rim edge (see

Fig. 53

).

Fig. 53

• Turn the mandrel and smear the entire bead seat

of the rim with lubricant. While doing this, jerk the

beading disc forward until the first bead is removed

(as these wheels feature inner tubes, carry out the

operation carefully, paying special attention to when

the bead dislodges, trying to stop disc advancement

immediately to avoid compromising the integrity of

the inner tube and valve).

• Place the tools holder arm in “out of work” position

(

Fig. 22 ref. 1

), operate the handle control in order

to position the tools holder arm on the wheel outer

side, then place it in “working position” (

Fig. 21

ref. 1

) again and lock it with the safety hook pro-

vided.

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15