III. ENGINE REPAIR

55

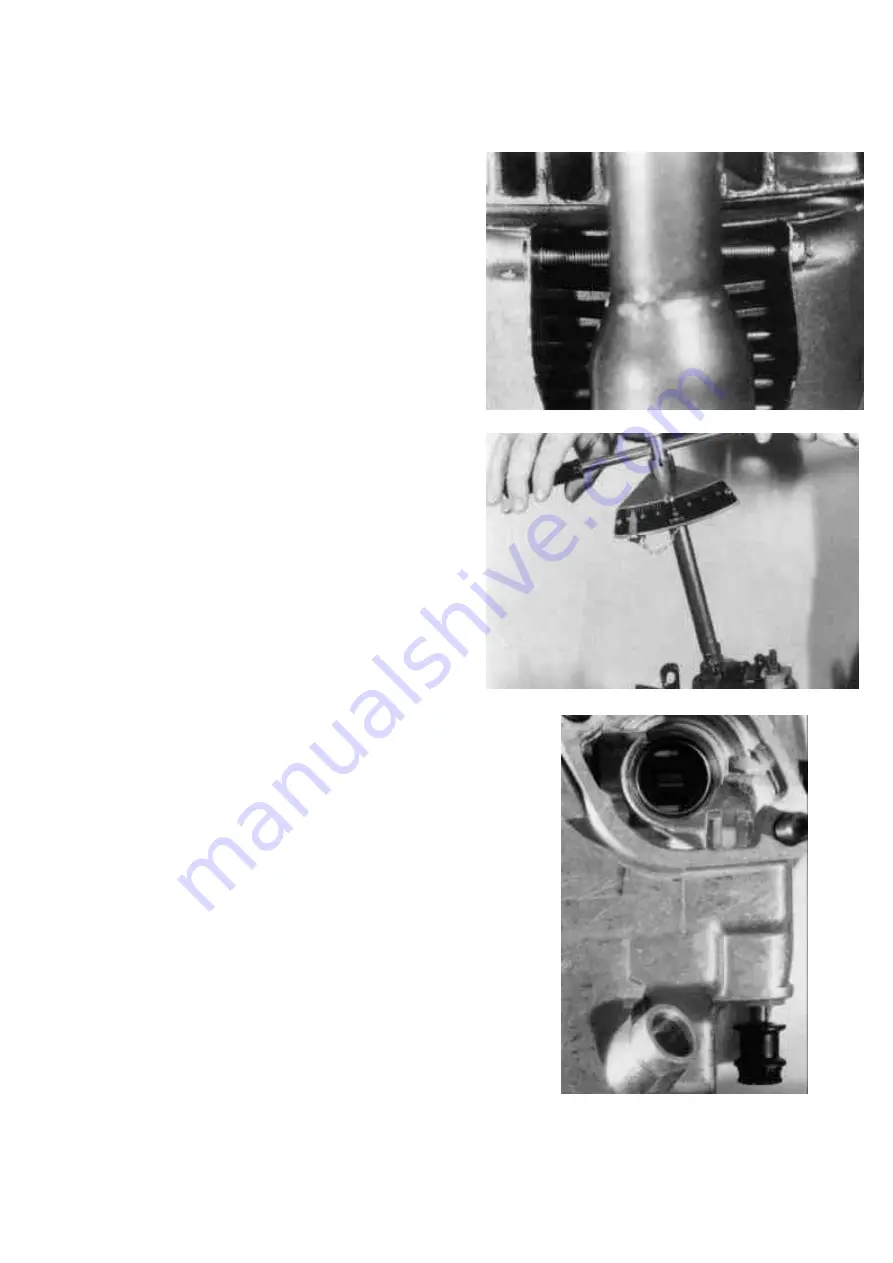

18. Cylinder shields and air

guides

Install both halves of cylinder shields and

the clamping bolt. Do not overtighten the

bolt. It is sufficient when the bold protrudes

about 1-2 mm (0.0394“-0.0787“) out of the

locknut. Install the two air guides on top of

the crankcase.

(Figure 36)

19. Fuel injector

Replace the special washer located in the

cylinder head fuel injector seat.

Attention: Use one gasket only, make

sure that the old one has been taken out.

Install the injector and the clamp. Torque

the two nuts as specified.

(Figure 37)

20. Injection pump

Place acceleration lever in full load position

and pull excess fuel button. The internal

spring pushes the control lever against the

housing. Place rod of the „fuel injection“.

When sliding in the pump the pin of the rod

directly grips into the yoke of the control

lever. Reinstall the injection pump by using

the same number and types of shims as

were on the engine before (see III.5 for

complete injection timing info.)

Attention: First install the paper gasket,

then the shims onto the stud. Shims

should not be in direct contact with the

housing due to insufficient sealing

function.

(Figure 38)

Summary of Contents for 15D Series

Page 8: ...III 1 DISASSEMBLY 10...

Page 9: ...II TECHNICAL DATA 11...

Page 15: ......

Page 27: ...III ENGINE REPAIR 28 III 2 DIMENSION TABLE WEARING PARTS...

Page 28: ...III ENGINE REPAIR 29...

Page 29: ...III ENGINE REPAIR 30...

Page 30: ...III ENGINE REPAIR 31...

Page 31: ...III ENGINE REPAIR 32...

Page 32: ...III ENGINE REPAIR 33...

Page 33: ...III ENGINE REPAIR 34...

Page 34: ...III ENGINE REPAIR 35...

Page 35: ...III ENGINE REPAIR 36...

Page 36: ...III ENGINE REPAIR 37...

Page 37: ...III ENGINE REPAIR 38...

Page 38: ...III ENGINE REPAIR 39...

Page 39: ...III ENGINE REPAIR 40...

Page 40: ...III ENGINE REPAIR 41...

Page 41: ...III ENGINE REPAIR 42 III 3 ENGINE REASSEMBLY...

Page 73: ...74...

Page 74: ...75...

Page 75: ...76...

Page 76: ...77...