1

Revision date: 09.21.18

©2018 FarmTek

®

All Rights Reserved. Reproduction

is prohibited without permission.

*Actual system may differ slightly from what is shown.

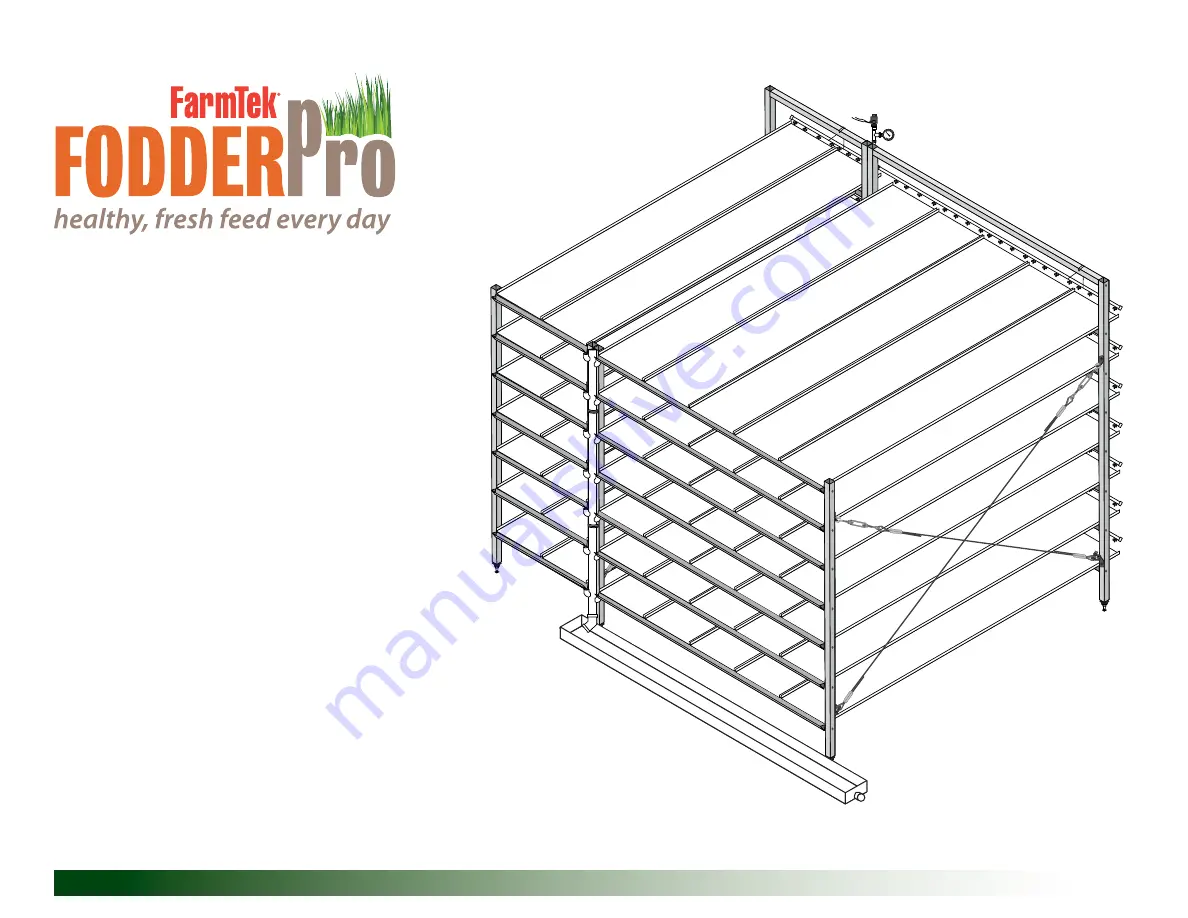

FodderPro 3.0 Commercial

Feed Systems–113542

"...grow your own nutrient-rich fodder..."

psi

0

40

20

60

80

10

0