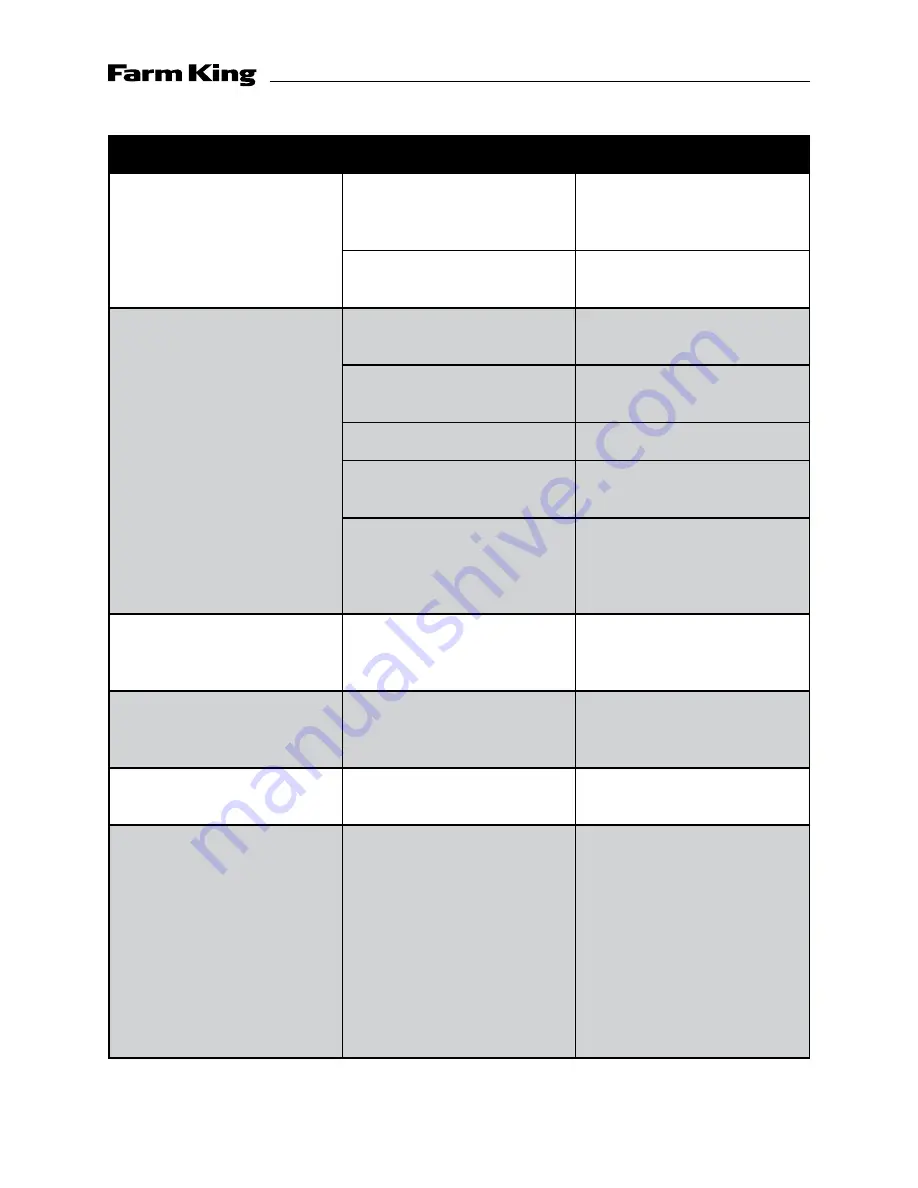

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Loss of hydraulic fluid due

to leakage

Fittings and tubes leaking

Tighten loose fittings and

replace worn hoses of

cracked tubing

Leakage between flange and

housing

Repair or replace

Low discharge of the

hydraulically driven liquid

pump

Pump not primed

Check vent line and clean if

necessary to top of tank

Air leaks in suction line

Check and reseal inlet

fittings

Blocked/clogged line strainer

Clean out and replace

Impeller plugged or loose

Inspect and clear obstruction

or tighten

Bypass adjustment set

improperly

Adjust bypass screw

on side of hydraulic

motor to manufacturer’s

specifications

Poor spray pattern, nozzles

dribble

Nozzles too large

Strainer clogged

See nozzle supplier

Clean strainer

Spray atomizing and

blowing around

Nozzle too small

Tractor speed too fast

See nozzle supplier

Reduce speed

Spray streaming

(No uniform pattern)

Nozzle partially clogged

Remove and clean nozzles

and strainer

Will not spray

Controller not setup

Valves not in correct

position

Poor hydraulics or no

hydraulic power

Liquid supply blocked

Suction line collapsed

See control manual

See Section B

Troubleshoot hydraulic

system

Clean strainer

Inspect and replace

Maintenance, Service & Troubleshooting - Section E

49

Summary of Contents for 1600

Page 1: ...Operator and Parts Manual 1600 High Clearance Sprayer 04 2010 SXL 26030 ...

Page 5: ...Safety Instruction Section A 5 ...

Page 11: ...Safety Decal Placement Safety Instructions Section A 11 ...

Page 12: ...Notes Safety Instructions Section A 12 ...

Page 13: ...Operation Instructions Section B 13 ...

Page 29: ...Connection Startup Section C 29 ...

Page 38: ...Connection Startup Section C Notes 38 ...

Page 39: ...Storage Section D 39 ...

Page 43: ...Maintenance Service Troubleshooting Section E 43 ...

Page 50: ...Maintenance Service Troubleshooting Section E Notes 50 ...

Page 51: ...Parts Schematics Section F 51 ...

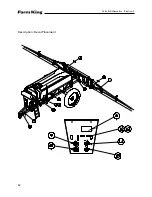

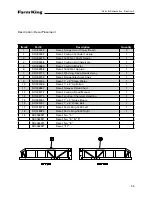

Page 52: ...19 Description Decal Placement Parts Schematics Section F 52 ...

Page 54: ...Description Trailer Sprayer Light Kit Assembly Parts Schematics Section F 54 ...

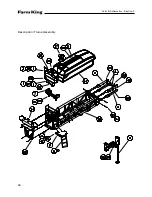

Page 56: ...Description Frame Assembly Parts Schematics Section F 56 ...

Page 58: ...Description Drawbar Assembly Parts Schematics Section F 58 ...

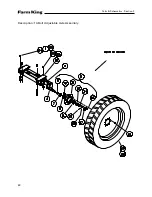

Page 60: ...Description 10 Bolt Adjustable Axle Assembly Parts Schematics Section F 60 ...

Page 62: ...Description Cradle Assembly Parts Schematics Section F 62 ...

Page 64: ...Description Tank Spreader and Sight Gauge Parts Schematics Section F 64 ...

Page 66: ...Parts Schematics Section F Description Fold Over the Top Boom Center Section Assembly 66 ...

Page 68: ...Description Fold Boom Primary Section Assembly Parts Schematics Section F 68 ...

Page 70: ...Description Fold Boom Secondary Breakaway Assembly Parts Schematics Section F 70 ...

Page 72: ...Parts Schematics Section F Notes 72 ...

Page 74: ...Description Sprayer Hydraulic Routing Parts Schematics Section F 74 ...

Page 76: ...Description Fold Over The Top Boom Hydraulic Valve Breakdown Parts Schematics Section F 76 ...

Page 79: ...Parts Schematics Section F Notes 79 ...

Page 82: ...Description Spray Boom Cylinder Assembly Parts Schematics Section F 82 ...

Page 84: ...Description Boom Rephasing Cylinder Assembly Parts Schematics Section F 84 ...

Page 86: ...Description Pump Plumbing Parts Schematics Section F 86 ...

Page 88: ...Parts Schematics Section F Description Tank Plumbing 88 ...

Page 90: ...Description Raven Control Plumbing Parts Schematics Section F 90 ...

Page 93: ...Parts Schematics Section F Notes 93 ...

Page 94: ...Description Valve Mounting 94 Parts Schematics Section F ...

Page 96: ...Description Fold Over the Top Boom Plumbing Kit Parts Schematics Section F 96 ...

Page 98: ...Description Manual Fence Row Plumbing Parts Schematics Section F 98 ...

Page 100: ...Description Eductor Assembly Parts Schematics Section F 100 ...

Page 103: ...Warranty Section G 103 ...