WARNING

004774

KEEP HANDS AND

BODY AWAY FROM

AREAS WHICH

EJECT FLUIDS UNDER

HIGH PRESSURE

CAUTION

USE CYLINDER LOCKUP WHEN

SERVICING OR STORING UNIT

Hydraulics

1. Inspect cylinder shafts for corrosion or damage. Repair

or replace shaft to avoid hydraulic leaks or cylinder

failure.

2. Inspect hydraulic hoses. Replace any hose that shows

signs of wear or damage.

3. Removing hydraulic hoses for any reason requires that

you plumb them back to their original position. Failure

to do this may result in incorrect operation and may

damage the sprayer. See Section F for the hydraulic

plumbing schematic.

IMPORTANT

Failure to plumb the parallel cylinders correctly may

cause damage to the Henschen suspension.

Electrical & Control System

Use of dielectric grease is strongly urged for all electrical

wire connections. All connections should be greased at

the beginning of the season. Poor electrical connections

due to corrosion is the leading cause of failure of sprayer

equipment in this environment.

Packard style connections on certain options are designed

to be weather resistant. This feature greatly reduces the

corrosion associated with electric connectors. Use of

dielectric grease is optional on these connections.

Maintenance, Service & Troubleshooting - Section E

DANGER

TO AVOID INJURY OR DEATH

KEEP EVERYONE CLEAR OF

MACHINE WHEN FOLDING

OR UNFOLDING WINGS

45

Summary of Contents for 1600

Page 1: ...Operator and Parts Manual 1600 High Clearance Sprayer 04 2010 SXL 26030 ...

Page 5: ...Safety Instruction Section A 5 ...

Page 11: ...Safety Decal Placement Safety Instructions Section A 11 ...

Page 12: ...Notes Safety Instructions Section A 12 ...

Page 13: ...Operation Instructions Section B 13 ...

Page 29: ...Connection Startup Section C 29 ...

Page 38: ...Connection Startup Section C Notes 38 ...

Page 39: ...Storage Section D 39 ...

Page 43: ...Maintenance Service Troubleshooting Section E 43 ...

Page 50: ...Maintenance Service Troubleshooting Section E Notes 50 ...

Page 51: ...Parts Schematics Section F 51 ...

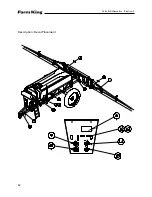

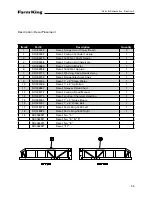

Page 52: ...19 Description Decal Placement Parts Schematics Section F 52 ...

Page 54: ...Description Trailer Sprayer Light Kit Assembly Parts Schematics Section F 54 ...

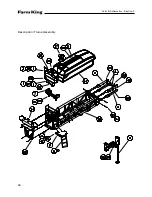

Page 56: ...Description Frame Assembly Parts Schematics Section F 56 ...

Page 58: ...Description Drawbar Assembly Parts Schematics Section F 58 ...

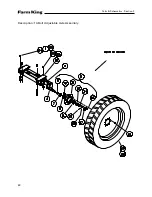

Page 60: ...Description 10 Bolt Adjustable Axle Assembly Parts Schematics Section F 60 ...

Page 62: ...Description Cradle Assembly Parts Schematics Section F 62 ...

Page 64: ...Description Tank Spreader and Sight Gauge Parts Schematics Section F 64 ...

Page 66: ...Parts Schematics Section F Description Fold Over the Top Boom Center Section Assembly 66 ...

Page 68: ...Description Fold Boom Primary Section Assembly Parts Schematics Section F 68 ...

Page 70: ...Description Fold Boom Secondary Breakaway Assembly Parts Schematics Section F 70 ...

Page 72: ...Parts Schematics Section F Notes 72 ...

Page 74: ...Description Sprayer Hydraulic Routing Parts Schematics Section F 74 ...

Page 76: ...Description Fold Over The Top Boom Hydraulic Valve Breakdown Parts Schematics Section F 76 ...

Page 79: ...Parts Schematics Section F Notes 79 ...

Page 82: ...Description Spray Boom Cylinder Assembly Parts Schematics Section F 82 ...

Page 84: ...Description Boom Rephasing Cylinder Assembly Parts Schematics Section F 84 ...

Page 86: ...Description Pump Plumbing Parts Schematics Section F 86 ...

Page 88: ...Parts Schematics Section F Description Tank Plumbing 88 ...

Page 90: ...Description Raven Control Plumbing Parts Schematics Section F 90 ...

Page 93: ...Parts Schematics Section F Notes 93 ...

Page 94: ...Description Valve Mounting 94 Parts Schematics Section F ...

Page 96: ...Description Fold Over the Top Boom Plumbing Kit Parts Schematics Section F 96 ...

Page 98: ...Description Manual Fence Row Plumbing Parts Schematics Section F 98 ...

Page 100: ...Description Eductor Assembly Parts Schematics Section F 100 ...

Page 103: ...Warranty Section G 103 ...