MHLL05 Rev A

012920

11

Step 1:

Determine the location of the end anchorages and, in accordance with Section 3.2, evaluate their strength. Determine the span

length of the system and determine the minimum required clearance for safe use in accordance with Section 2.7.

Step 2:

Install the end anchorage connectors. The FallTech 4-Person Temporary HLL system comes with 2 pass-through anchor straps for

wrapping around columns. If using pass through anchor straps, ensure strap is wrapped at least twice around the end anchorage, see

Figure 9. This will help prevent sliding of the anchor straps during use. If using alternative anchorage connectors, please ensure the

connectors are compliant and conform to the requirements of Section 3.2. Not all anchorage connectors are designed for use with

horizontal lifeline systems. In all cases, refer to the user’s instruction manual for the end anchorage connectors to be used.

Step 3:

Secure the HLL system to the anchorage connectors with the provided end attachment carabiners.

4.5

Product Assembly and Installation:

System installation requires end anchor points that are a minimum of 6,000 lbs. (26.7 kN) in both

vertical and horizontal directions for three and four workers and 5,000 lbs. (22.2 kN) for one and two workers, see Figure 8. The

lifeline shall be installed to limit free fall to 6’ or less*. When using SRDs the lifeline must be positioned overhead. The horizontal lifeline

should be positioned in a manner to minimize free fall while allowing ease of use. Movement away from the lifeline should be limited

to reduce the potential for swing fall. Lifeline end anchors should be installed at approximately the same elevation so that the lifeline

itself is not sloped more than 5 degrees.

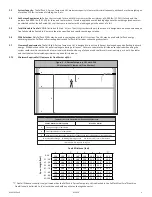

Figure 8 - Anchorage Strength Requirements

5,000lbs (22.2kN) Minimum

for one and two workers

6,000lbs (26.7kN) Minimum

for three and four workers

Or

5,000lbs (22.2kN) Minimum

for one and two workers

6,000lbs (26.7kN) Minimum

for three and four workers

Or

5,000lbs (22.2kN) Minimum

for one and two workers

6,000lbs (26.7kN) Minimum

for three and four workers

Or

5,000lbs (22.2kN) Minimum

for one and two workers

6,000lbs (26.7kN) Minimum

for three and four workers

Or

Figure 9 - Pass-Through Anchor Strap Installation