INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

20

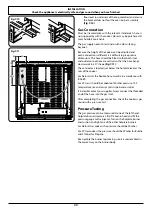

floor level to underside of the top member) and ensure

the bracket does not foul the oven burner assembly

(Fig.7-10)

.

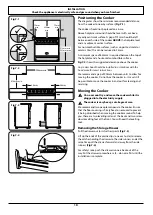

Gas Connection

Must be in accordance with the relevant standards. A hose is

not supplied by with the cooker. Hoses may be purchased at

most builders’ merchants.

The gas supply needs to terminate with a down facing

bayonet.

Because the height of the cooker can be adjusted and

each connection is different it is difficult to give precise

dimensions. The hose should be fitted so that both inlet

and outlet connections are vertical so that the hose hangs

downwards in a ‘U’ shape

(Fig.7-11)

.

The connector is located just below the hotplate level at the

rear of the cooker.

For Natural Gas the flexible hose must be in accordance with

B.S.669.

For LP Gas it should be capable of 50mbar pressure, 70°C

temperature rise and carry a red stripe, band or label.

If in doubt contact your supplier. Screw connect the threaded

end of the hose into the gas inlet.

After completing the gas connection, check the cooker is gas

sound with a pressure test.

Pressure Testing

The gas pressure can be measured at one of the left-hand

hotplate burner injectors. Lift off a burner head and fit the

pressure gauge to the injector. Turn on the hotplate burner

and turn on and light one of the other hotplate burners.

For Natural Gas cookers the pressure should be 20mbar.

For LP Gas cookers the pressure should be 29mbar for Butane

and 37mbar for Propane.

Reassemble the burner top making sure it is reassembled in

the correct way on the burner body.

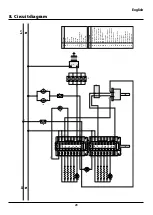

ArtNo.062-0002 - 90SC - Prof+ - Gas connection

��

���

���

��

���

Fig.7-11

ArtNo.070-0005 - Stability bracket

Fig.7-10