Panel PC.

CNC 8065

3.

·51·

(R

EF

: 1801)

PPC-21W.

3.4.3

Securing the module.

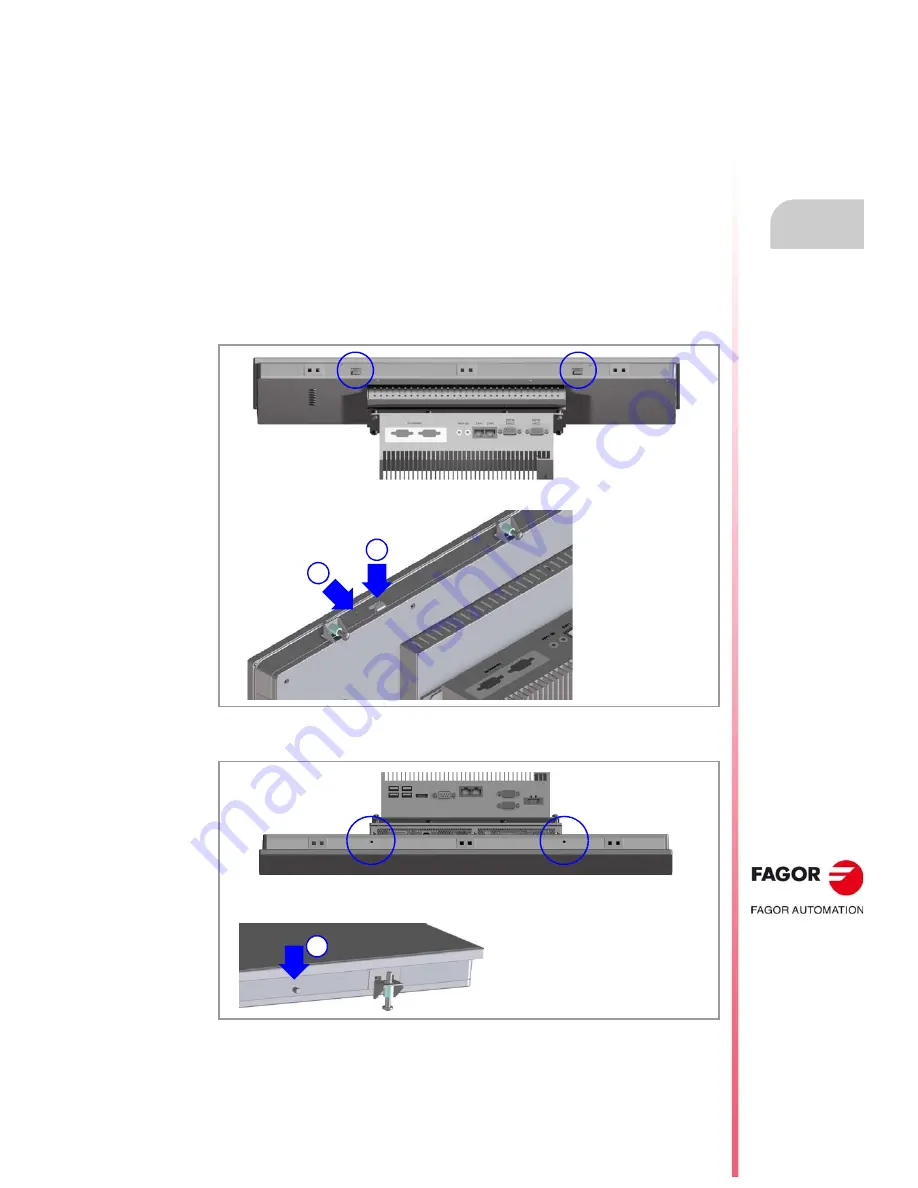

The module must be installed in a proper enclosure that may be located on the machine or

on an external support. To insert the unit into the enclosure, it must have a big enough hole

to allow to insert it easily, without obstacles and without forcing the unit. Once the unit has

been inserted into the enclosure, secure it from the inside with the tension jacks. To properly

secure it, use all the tension jacks on the back of the unit. Apply a tightening torque of 0.7 Nm.

Mounting the equipment.

Follow the instructions below.

1

Before inserting the equipment inside the enclosure, use the two upper screws (A) to

attach the temporary fastening hooks (B) in the desired position. These hooks facilitate

the assembly by temporarily securing the module until it is permanently supported at the

rear using the 12 fastening attachments. These two hooks should never be used as the

final attachment fixture.

2

Adjust the two lower stop screws (C) to hold the PPC-21W at the correct height.

A

B

C

Summary of Contents for 8060 M Power

Page 1: ...Ref 1801 8065 CNC Panel PC...

Page 10: ...BLANK PAGE 10...

Page 12: ...BLANK PAGE 12...

Page 16: ...BLANK PAGE 16...

Page 18: ...BLANK PAGE 18...

Page 20: ...BLANK PAGE 20...

Page 22: ...Panel PC CNC 8065 1 22 REF 1801 PREVIOUS INFORMATION...

Page 42: ...Panel PC CNC 8065 2 42 REF 1801 MONITOR 21 MULTITOUCH...

Page 72: ...Panel PC CNC 8065 3 72 REF 1801 PPC 21W...

Page 90: ...Panel PC CNC 8065 5 90 REF 1801 FAGORCONNECT APPLICATION...

Page 91: ...Panel PC CNC 8065 91 User notes REF 1801...

Page 92: ...Panel PC CNC 8065 92 User notes REF 1801...