P a g e

|

2

STEP 1

Please ensure that the door is free swinging, not binding and any closers (such as surface mount, in-

head pivot closers, hinge closers) are removed prior to commencement of installation.

STEP 2

Depending on the type of arm being used, there will be inside the box a 1:1 Scale Mounting Template

(See below). Please use this template for the position of the mounting holes, both for the operator

and the arm. If for any reason, this is not available please refer to the 950N2 manual and pages 13

through to 16 for the mounting holes positions.

Please also use appropriate fixings for the material that you are fixing the operator to. In General,

60mm of Softwood, 40mm of Hardwood, 10mm of Aluminium or 6mm of Steel.

STEP 3

Once the operator and arm are mounted to the door and header, connect the main power to the

950N2 ensure that the earth is securely connected. (See below)

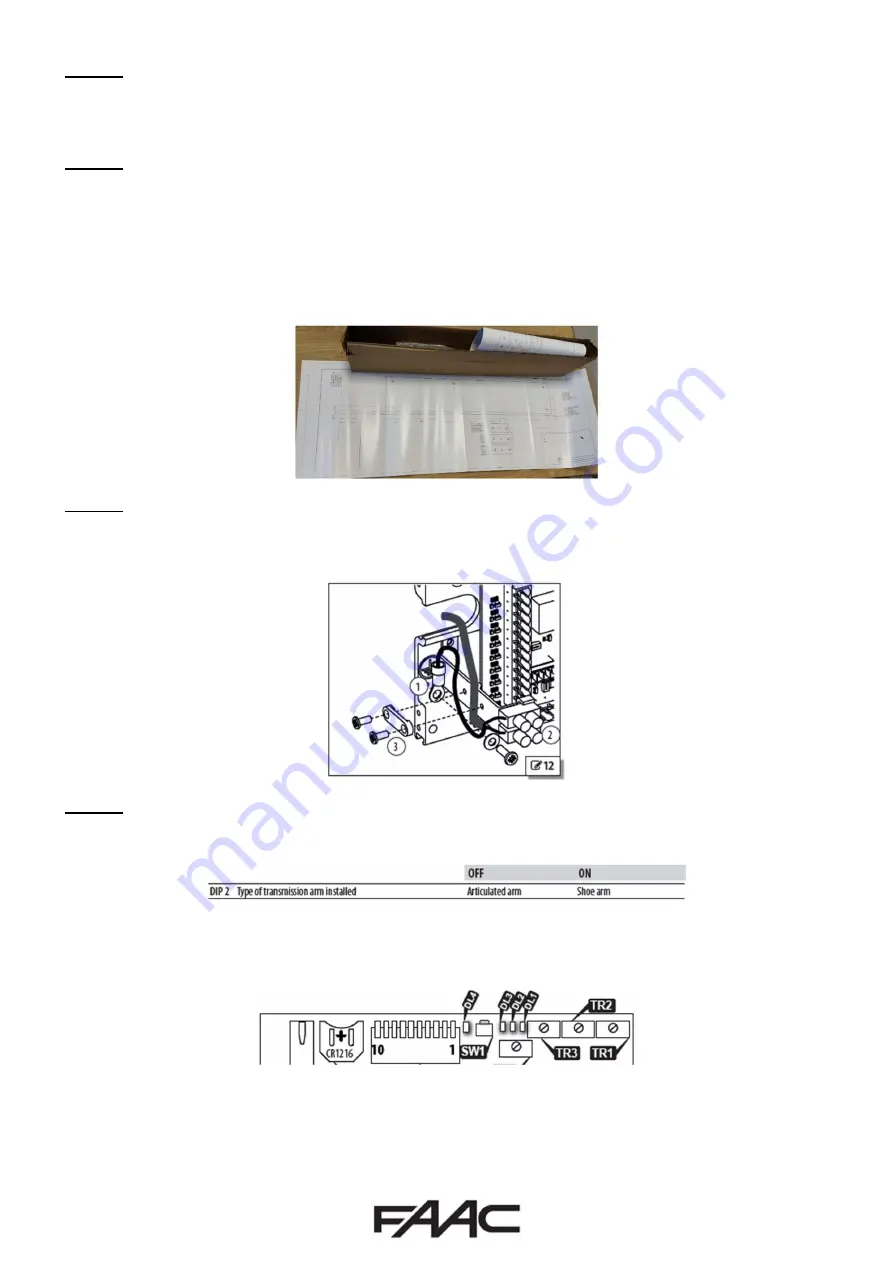

STEP 4

Depending on the arm used, adjust DIPSWITCH “2” accordingly as per below.

Once adjusted, DL4 on the Logic Board will illuminate “YELLOW” (See below). This is to identify that

a change is made on the DIPSWITCH or TRIMMER banks. The changes will only take effect when SW1

(See below) is pressed for 1.5secs on the Logic Board.

Please note that if the KP EVO is used for Programming, DL4 will illuminate “YELLOW” but

DO NOT

press SW1 as this will revert back to DIPSWITCH or TRIMMER setting.